Preparation method of highly dispersed Pd-IL/Al2O3 catalyst and application of same in selective hydrogenation reaction of acetylene

A catalyst, acetylene technology, used in physical/chemical process catalysts, catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of low ethylene selectivity, improve conversion rate, prevent excessive hydrogenation , the effect of superior catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

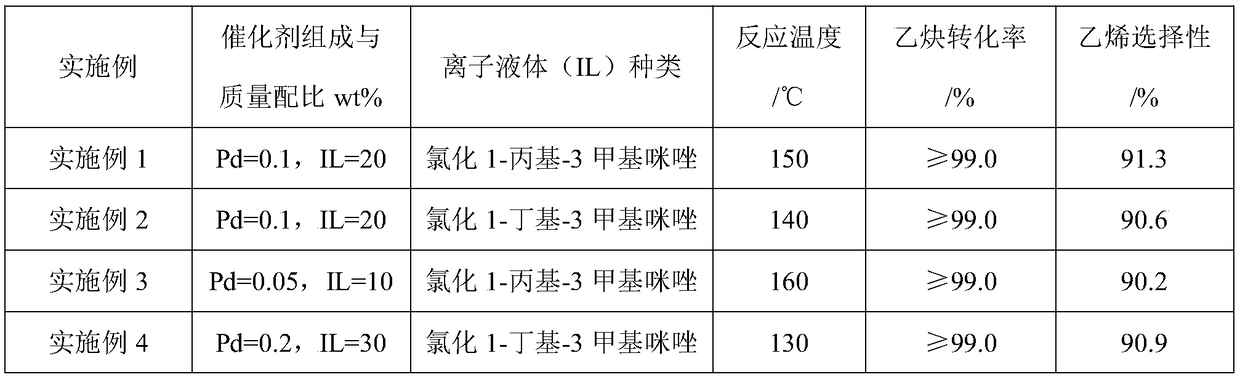

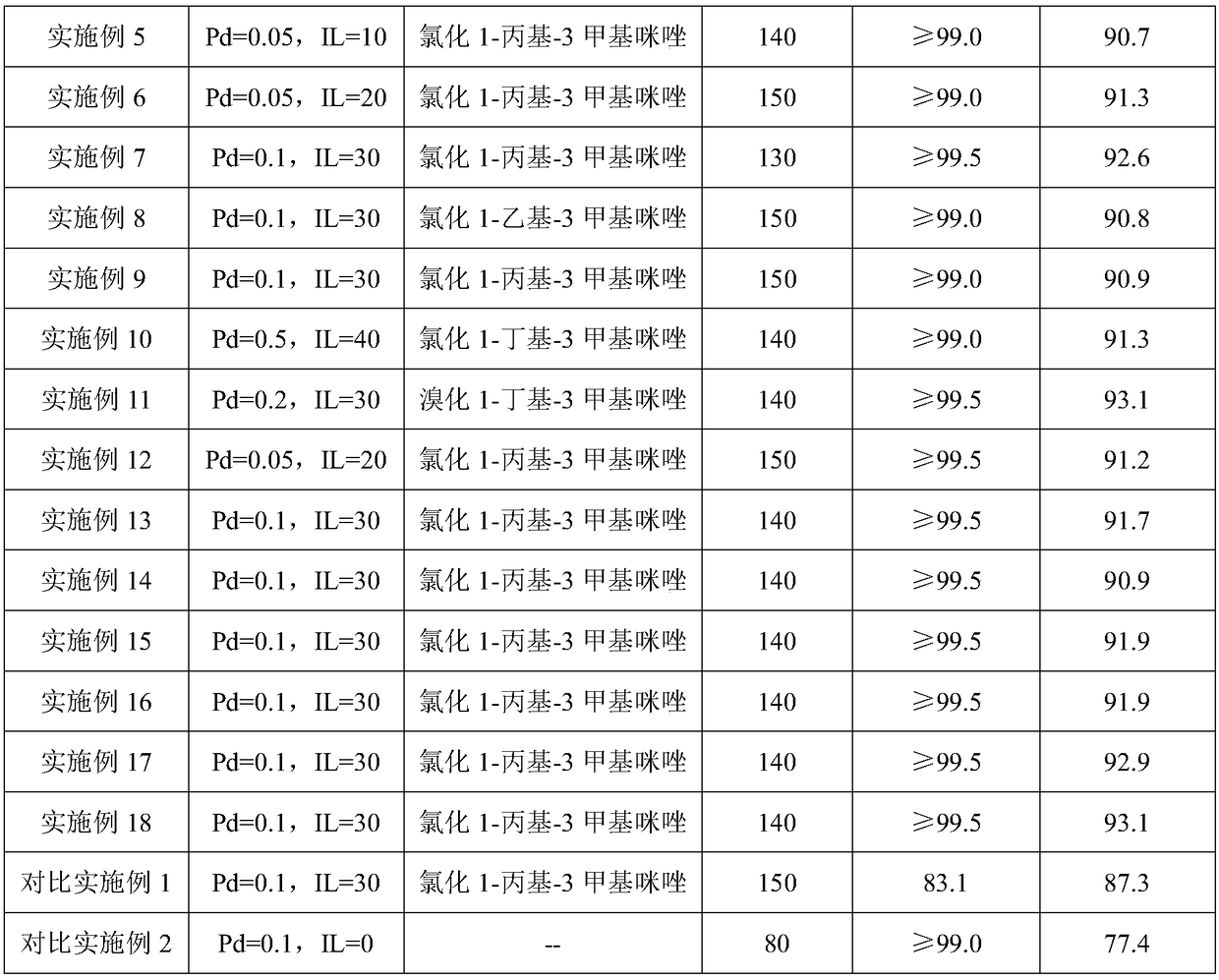

Embodiment 1-4

[0024] Using the impregnation method, according to the load listed in Table 1, the metered palladium dichloride is mixed with DMF, after stirring evenly, the alumina carrier (specific surface area is 384m 2 / g) Evenly pour into the impregnating liquid, and use ultrasonic to make it disperse evenly. Immerse at room temperature for 12 hours and dry at 110°C for 12 hours to obtain a certain load of Pd / Al 2 o 3 catalyst. The dried Pd / Al 2 o 3 Put the catalyst into a tube furnace and bake it in the air, and bake it at 300°C for 2 hours to get highly dispersed Pd / Al 2 o 3 catalyst.

[0025] Using the impregnation method, weigh the ionic liquid (IL) according to the load listed in Table 1, and dissolve it in deionized water; after stirring evenly, weigh a certain amount of highly dispersed Pd / Al obtained by roasting 2 o 3 Catalyst, evenly poured into the well-mixed solution, and ultrasonically dispersed evenly, the wet carrier was impregnated at room temperature for 12h, and ...

Embodiment 5-7

[0027] Using the impregnation method, according to the load listed in Table 1, the metered palladium dichloride is mixed with DMF, after stirring evenly, the alumina carrier (specific surface area is 384m 2 / g) Evenly pour into the impregnating liquid, and use ultrasonic to make it disperse evenly. Immerse at room temperature for 12 hours and dry at 110°C for 12 hours to obtain a certain load of Pd / Al 2 o 3 catalyst. The dried Pd / Al 2 o 3 The catalyst is put into a tube furnace and calcined in the air, and calcined at 500°C for 2 hours to obtain highly dispersed Pd / Al 2 o 3 catalyst.

[0028] Using the impregnation method, weigh the ionic liquid (IL) according to the load listed in Table 1, and dissolve it in deionized water; after stirring evenly, weigh a certain amount of highly dispersed Pd / Al obtained by roasting 2 o 3 Catalyst, evenly poured into the well-mixed solution, and ultrasonically dispersed evenly, the wet carrier was impregnated at room temperature for 1...

Embodiment 8-10

[0030] Using the impregnation method, according to the load listed in Table 1, the metered palladium dichloride is mixed with DMF, after stirring evenly, the alumina carrier (specific surface area is 384m 2 / g) Evenly pour into the impregnating liquid, and use ultrasonic to make it disperse evenly. Immerse at room temperature for 12 hours and dry at 110°C for 12 hours to obtain a certain load of Pd / Al 2 o 3 catalyst. The dried Pd / Al 2 o 3 Put the catalyst into a tube furnace and bake it in the air, and bake it at 700°C for 2 hours to get highly dispersed Pd / Al 2 o 3 catalyst.

[0031] Using the impregnation method, weigh the ionic liquid (IL) according to the load listed in Table 1, and dissolve it in deionized water; after stirring evenly, weigh a certain amount of highly dispersed Pd / Al obtained by roasting 2 o 3 Catalyst, evenly poured into the well-mixed solution, and ultrasonically dispersed evenly, the wet carrier was impregnated at room temperature for 12h, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com