Micro-pore acellular porcine aorta matrix

A technology for aorta decellularization, applied in medical science, tissue regeneration, prostheses, etc., can solve the problems of porcine aortic matrix residual toxicity, difficult endogenous growth of cells, and biomechanical damage, etc., to achieve the preservation of three-dimensional structure and Biomechanical properties, reduced residual toxicity, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following examples will specifically illustrate the microporous decellularized porcine aortic matrix of the present invention in conjunction with the accompanying drawings.

[0021] figure 1 It is a schematic diagram of porcine aorta and microporous decellularized porcine aortic matrix in an embodiment of the present invention.

[0022] figure 2 It is a scanning electron microscope schematic diagram of porcine aorta and microporous decellularized porcine aortic matrix in the embodiment of the present invention.

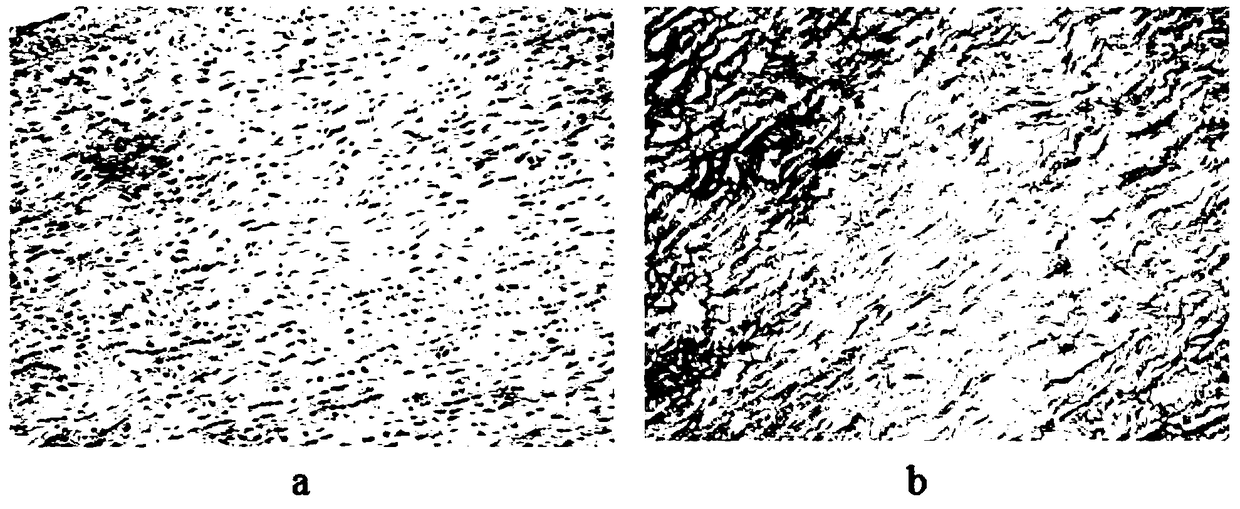

[0023] image 3 It is a histological schematic diagram of porcine aorta and microporous decellularized porcine aortic matrix in the embodiment of the present invention.

[0024] Such as Figure 1~3 as shown, figure 1 (a), figure 2 (a), image 3 (a) represents a normal porcine aorta, figure 1 (b), figure 2 (b), image 3 (b) rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com