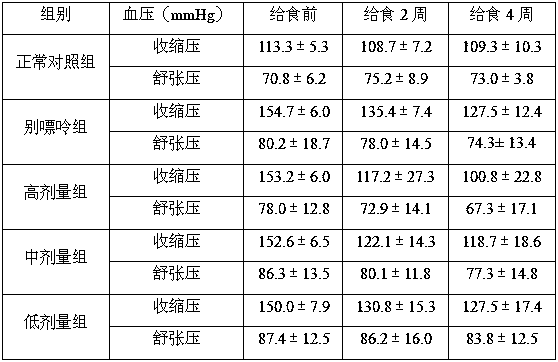

Pine needle enzymes, preparation method, blood-pressure-lowering total-nutrient formula food and edible method

A technology of formula food and pine needles, which is applied in the direction of vitamin-containing food ingredients, food ingredients, and the functions of food ingredients, and can solve the problems of no fortification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

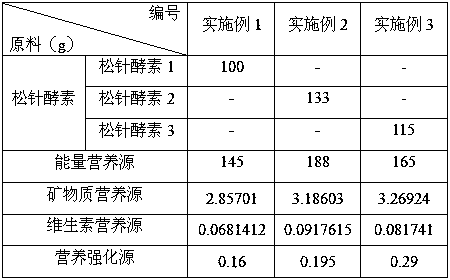

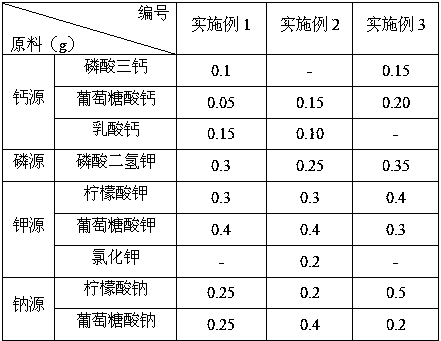

[0093] Pine needle enzyme embodiment 1~3 raw material components and ratio as shown in table 1:

[0094] Table 1 Raw material components and proportions of pine needle enzyme examples 1 to 3

[0095]

[0096] The preparation method embodiment 1 of pine needle enzyme

[0097] (1) According to the quality of the raw materials described in Example 1 in Table 1, wash the pine needles, pine pollen, edible flowers and edible fruits and vegetables with water, drain, mash, add the compound enzyme preparation and water, and carry out the enzyme preparation at 28°C. Decompose for 8 hours, filter with a filter membrane with a pore size of 1.5mm, and sterilize at 100°C for 10 minutes to obtain mixed pulp;

[0098] (2) According to the quality of each raw material described in Example 1 in Table 1, yeast was inoculated into the mixed pulp obtained in step (1), and left to ferment at 38°C for 12 days to obtain a fermentation broth;

[0099] (3) According to the quality of each raw mate...

Embodiment 2

[0101] (1) According to the quality of each raw material described in Table 1, Example 2, wash pine needles, pine pollen, edible flowers and edible fruits and vegetables with water, drain, mash, add compound enzyme preparation and water, and carry out enzyme Decompose for 4 hours, coarsely filter with a filter membrane with a pore size of 1.2mm, and sterilize at 110°C for 20 minutes to obtain mixed fruit pulp;

[0102] (2) According to the quality of each raw material described in Table 1, Example 2, yeast was inoculated into the mixed pulp obtained in step (1), and left to ferment at 40°C for 20 days to obtain a fermentation broth;

[0103] (3) According to the quality of each raw material described in Example 2 of Table 1, add lactic acid bacteria to the fermented liquid obtained in step (2), leave it to ferment for 20 days at 35°C, and post-ripen for 60 days to obtain pine needle enzyme 2.

Embodiment 3

[0105] (1) According to the quality of each raw material described in Example 3 in Table 1, wash pine needles, pine pollen, edible flowers and edible fruits and vegetables with water, drain, mash, add compound enzyme preparation and water, and carry out enzyme treatment at 30°C. Decompose for 6 hours, coarsely filter with a filter membrane with a pore size of 0.8mm, and sterilize at 105°C for 15 minutes to obtain mixed fruit pulp;

[0106] (2) According to the quality of each raw material described in Table 1, Example 3, yeast was inoculated into the mixed pulp obtained in step (1), and left to ferment at 42°C for 22 days to obtain a fermentation broth;

[0107] (3) According to the quality of each raw material described in Example 3 in Table 1, add lactic acid bacteria to the fermented liquid obtained in step (2), leave it to ferment at 40°C for 22 days, and post-ripen for 70 days to obtain pine needle enzyme 3.

[0108] The pine needle enzymes of Examples 1 to 3 of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com