Meat food preservation device and meat food shelf life extension method

A technology of meat food and fresh-keeping device, which is applied in the fields of food electrical processing, food science, preservation of meat/fish by radiation/electrical processing, etc., can solve the problems of high excitation voltage and high plasma temperature, and achieve mild processing conditions and reduced dangerous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

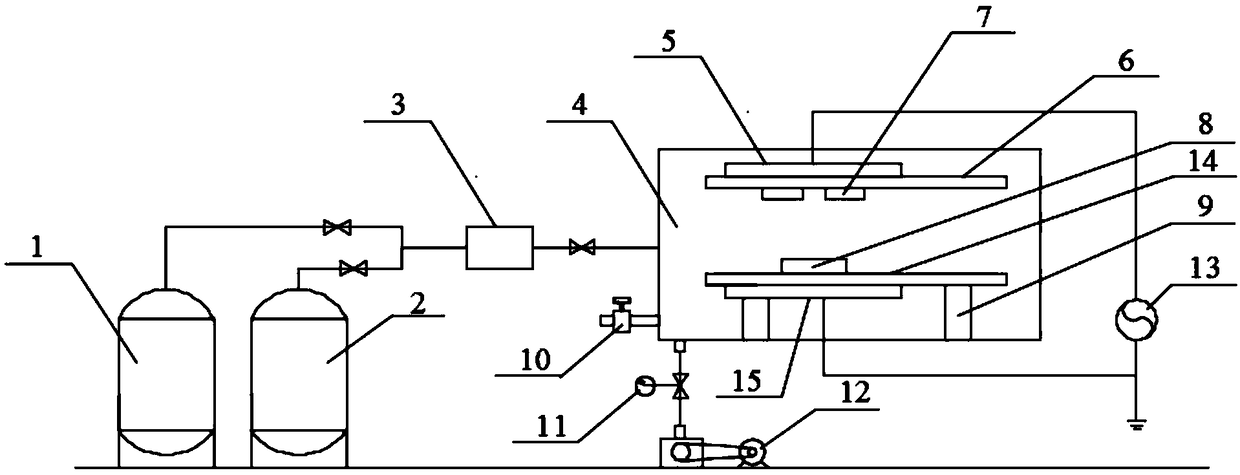

[0025] Such as figure 1 As shown, an upper high-voltage electrode 5 and a lower high-voltage electrode 15 are arranged oppositely up and down in the vacuum chamber 4, and the upper dielectric barrier layer 6 of a cylindrical quartz medium is coated around the upper high-voltage electrode 5, and the lower high-voltage electrode 15 A lower dielectric barrier layer 14 of a cylindrical quartz medium is coated around; an ultraviolet-visible lamp 7 is arranged below the upper dielectric barrier layer 6, and a sample is placed on the lower dielectric barrier layer 14; the lower high-voltage electrode 15 is supported by an insulating support 9 support. The vacuum chamber 4 communicates with the liquid nitrogen tank and the liquid oxygen tank respectively through a mixer. The vacuum chamber 4 is connected to the liquid nitrogen tank 1 and the liquid oxygen tank 2 through a mixer 3; the vacuum chamber 4 is also provided with a vent valve 10; the vacuum chamber 4 passes a vacuum pressur...

Embodiment 2

[0033] The meat preservation device adopted in this embodiment is the same as that in Embodiment 1. Specifically include the following steps:

[0034] (1) Obtaining the slaughtered fresh beef cut into 60×60×10mm and placing it in a tray;

[0035] (2) Adjust the vacuum system to obtain a certain degree of vacuum (5×10 2 Pa), and turn on the ultraviolet lamp to sterilize the environment;

[0036] (3) Turn on the DBD plasma equipment to obtain a high-voltage (100kV) plasma power supply, the frequency is controlled at 50Hz, the power is controlled at 500W, the gas flow rate is 15L / min, and the sample is processed for 8min. At the same time, the OES is controlled by the computer system and an infrared thermal imager to measure the plasma active components and the temperature of the sample after plasma treatment; in addition, the plasma gas source of this test is a mixed gas of liquid nitrogen and liquid oxygen, and the mixing ratio is 1:3.

[0037] (4) The processed samples were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com