Structure for lower portion of vehicle body

A body, front and rear technology of the body, applied to the superstructure, superstructure sub-assemblies, vehicle components, etc., can solve the problem of difficulty in ensuring the minimum ground clearance of the muffler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

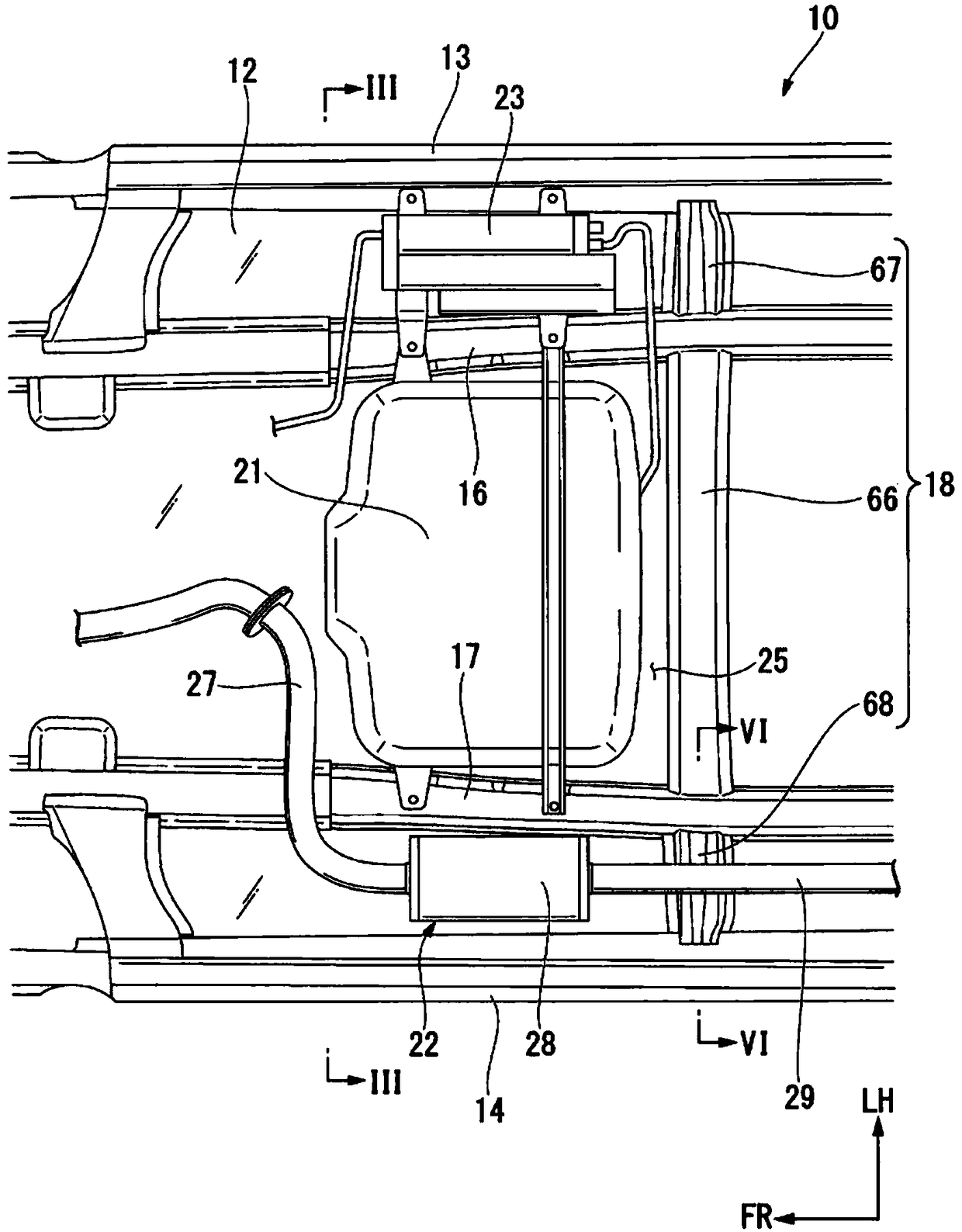

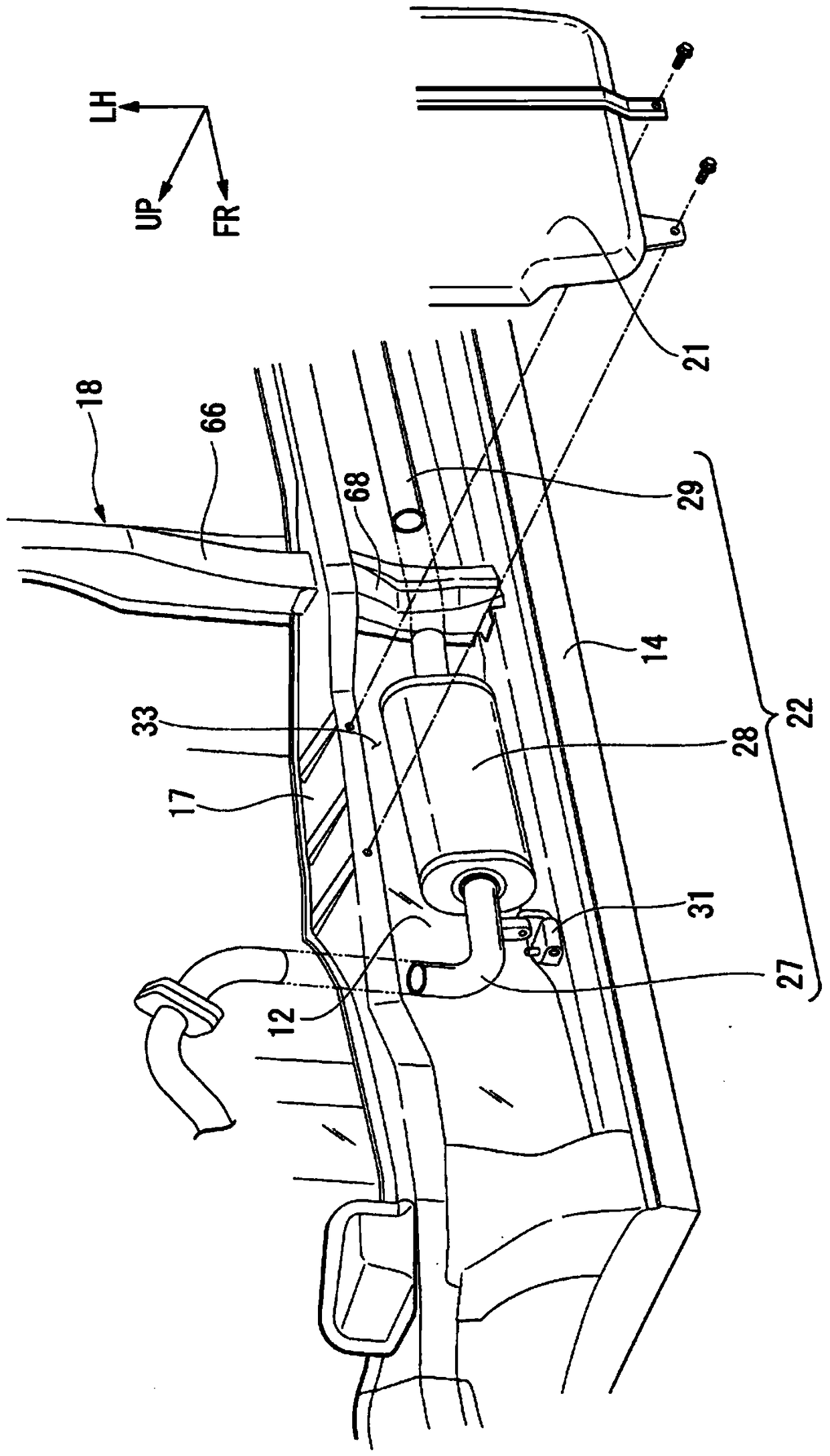

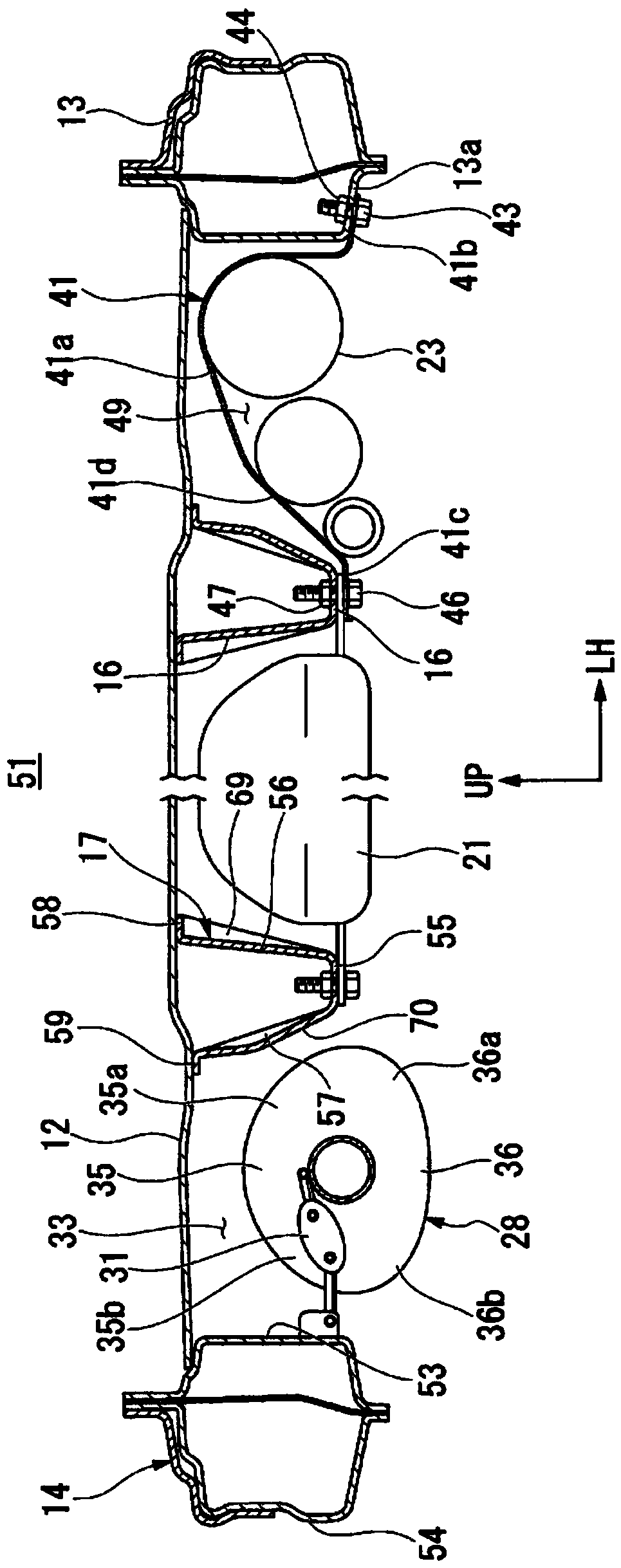

[0062] Such as figure 1 As shown, the vehicle body lower structure 10 includes a floor 12 , a left side sill 13 provided on the left side of the floor 12 , a right side sill 14 provided on the right side of the floor 12 , and a left floor frame 16 provided inside the left side sill 13 . , and the right floor frame 17 provided inside the right side sill 14 .

[0063] In addition, the vehicle body lower structure 10 includes a cross member 18 erected between the left side sill 13 and the right side sill 14 , a fuel tank 21 , an exhaust unit 22 , and a tank 23 .

[0064] The fuel tank 21 is provided in a region 25 below the floor panel 12 and in the center in the vehicle width direction. The area 25 is surrounded by the left floor frame 16, the right floor frame 17, and the beam 18 (specifically, the central beam 66). That is, the fuel tank 21 is provided on the inside of the left floor frame 16 in the vehicle width direction and on the inside of the right floor frame 17 in the...

no. 2 approach

[0161] The vehicle body lower structure 100 of the second embodiment will be described. In addition, in 2nd Embodiment, the same code|symbol is attached|subjected to the similar member same as 1st Embodiment, and detailed description is abbreviate|omitted.

[0162] Such as Figure 13 As shown, the vehicle body lower structure 100 assumes a state in which an in-vehicle component (muffler 28 ) is strongly sandwiched between the right side sill 102 and the right floor frame 17 .

[0163] In this case, the coefficient of friction of the inner side wall 103 of the right lower side sill 102 also needs to be considered.

[0164] The inner side wall 103 of the right side sill 102 has a predetermined coefficient of friction μ3. Therefore, when the impact load input to the right side sill 102 causes the upper deformation of the guide portion 77 (refer to Figure 9 (b)) In the upwardly deformed state, the muffler 28 is strongly sandwiched between the right side sill 102 and the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com