Chassis system and logistics vehicle

A chassis and frame technology, which is applied in the field of chassis systems and logistics vehicles, can solve the problems of inconvenient cargo loading and unloading and high ground clearance of the frame, and achieve the effects of convenient cargo loading and unloading, reduced ground clearance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

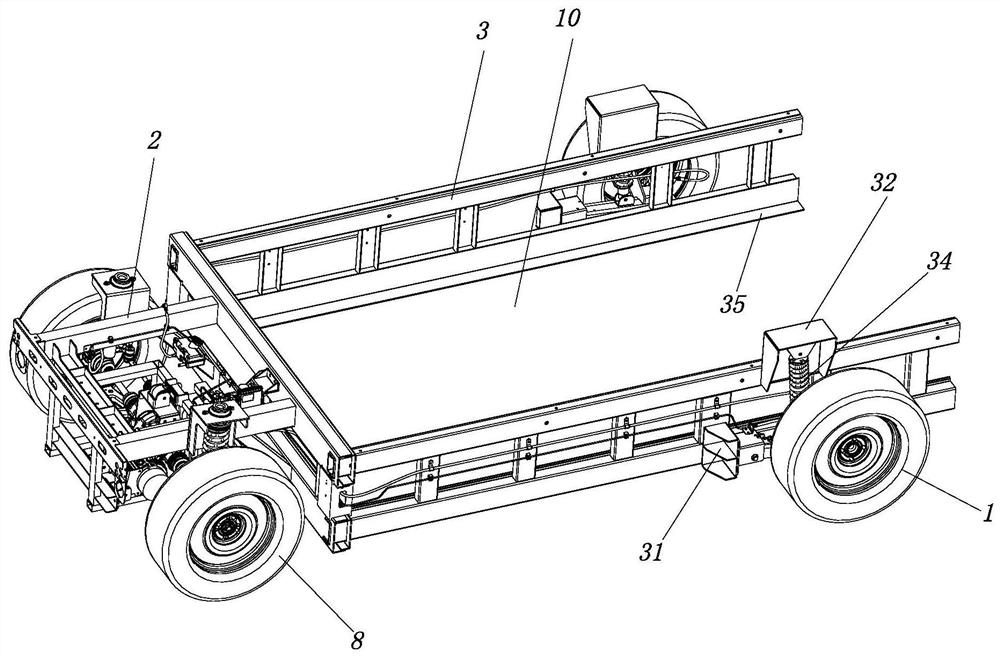

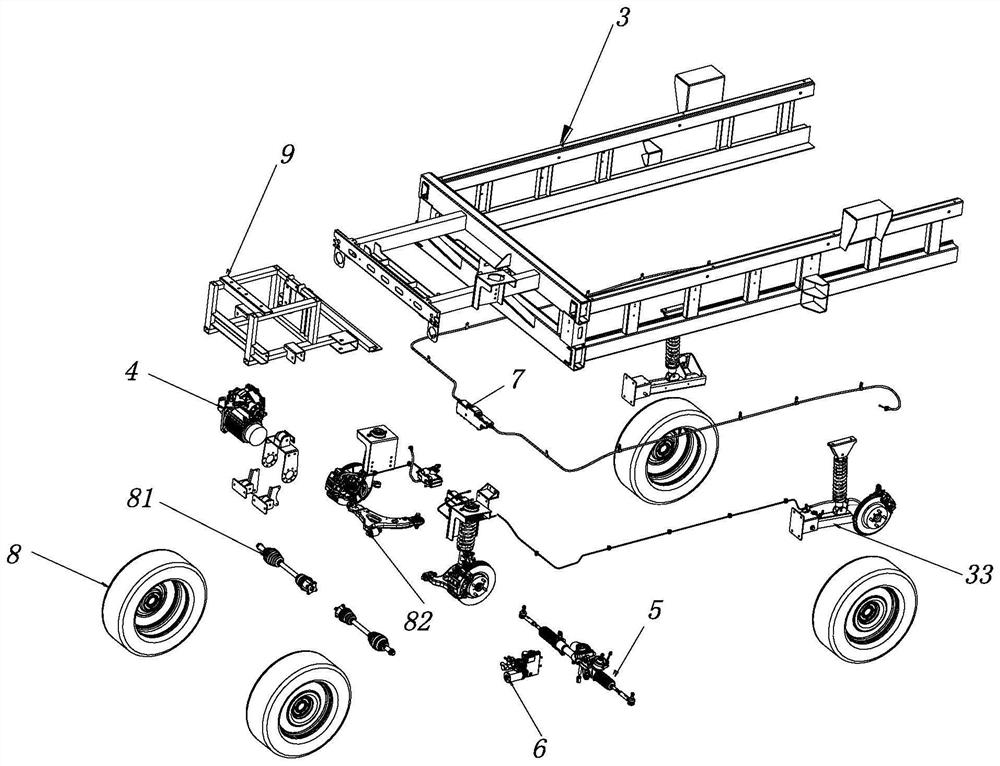

[0019] Figure 1 to Figure 2 An embodiment of the chassis system of the present invention is shown. The chassis system of this embodiment includes a vehicle frame. The vehicle frame includes a front frame 2 and two rear longitudinal beams 3 arranged in parallel. Cargo container layout area 10 (that is, the container is arranged in the area between two columns of longitudinal beams 3), the front end of rear longitudinal beam 3 is fixedly connected with front frame 2, and the rear end of rear longitudinal beam 3 is provided with mounting seat 31 and vibration damping The seat 32 and the mounting seat 31 are hinged with a trailing arm 33 , the rear wheel 1 is arranged on the trailing arm 33 , and a shock absorbing part 34 is arranged between the shock absorbing seat 32 and the trailing arm 33 .

[0020] The chassis system includes the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com