Injection molding apparatus and injection molding method

A technology of injection molding and forming molds, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of increased material cost, and achieve the effect of suppressing long-term and uniform conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]

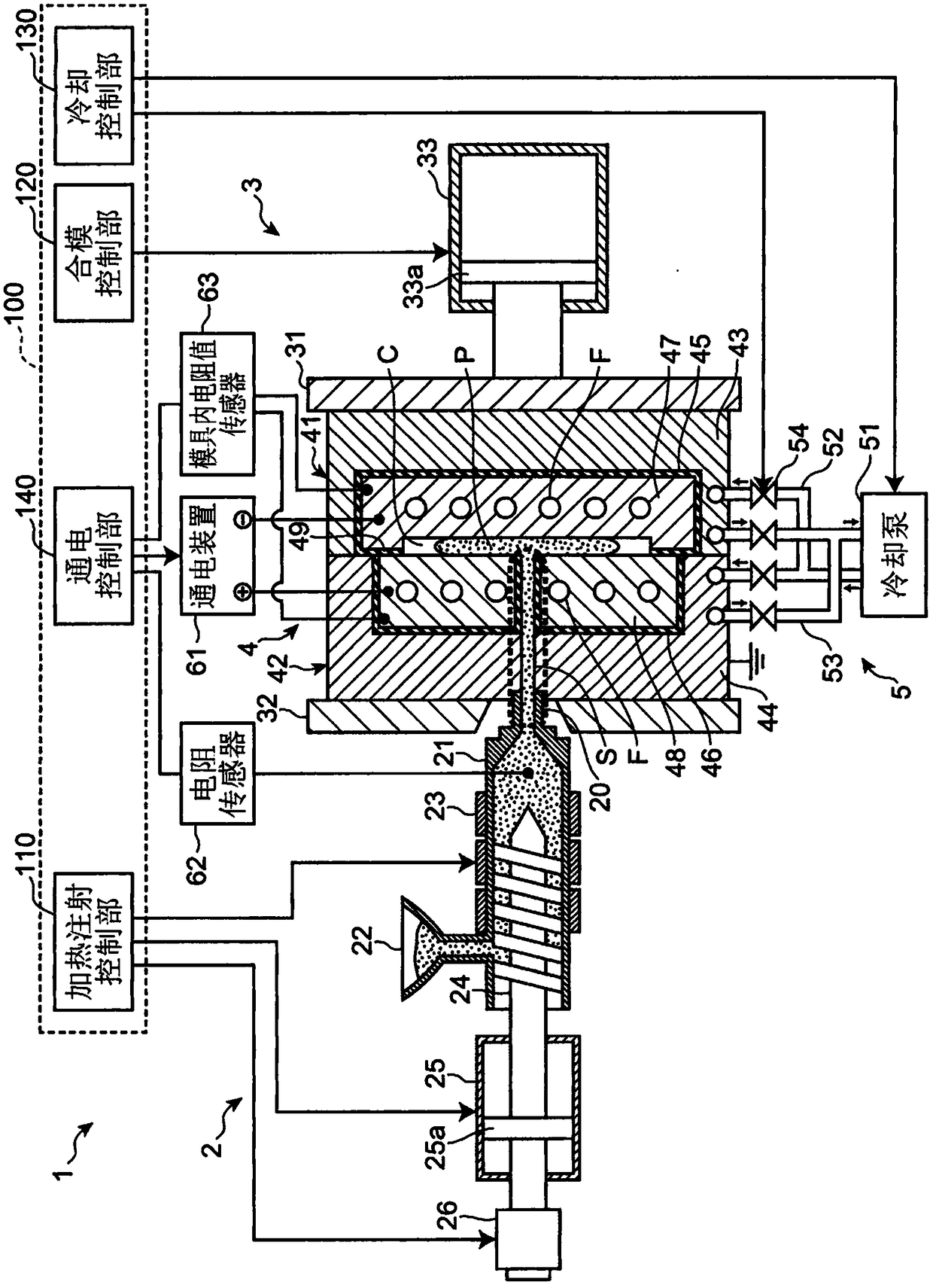

[0031] First, before describing the characteristic configuration of the injection molding apparatus of the present embodiment, the general configuration of the injection molding apparatus of the present embodiment will be described with reference to the drawings.

[0032] like figure 1 As shown, the injection molding apparatus 1 of this embodiment has the heating injection apparatus 2 and the mold clamping apparatus 3 provided so that the heating injection apparatus 2 may be opposed. The heating injection device 2 and the mold clamping device 3 are installed on a base frame (not shown).

[0033] (heated injection device)

[0034] The heated injection device 2 includes an injection cylinder 21 . A funnel 22 is attached to the upper part of the injection cylinder 21, and the funnel 22 is used for supplying the pelletized thermoplastic resin into the injection cylinder 21, and this thermoplastic resin becomes a raw material of a molded article. Around the injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com