A compression-resistant structure of a deep-water propulsion motor

A propulsion motor, deep water technology, applied in electrical components, electromechanical devices, electric components and other directions, can solve problems such as the inability to meet the working requirements of deep water motors, unscientific and reasonable sealing structure, etc., to achieve the effect of enhanced pressure resistance and smooth driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

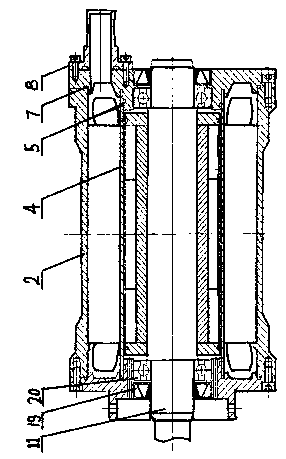

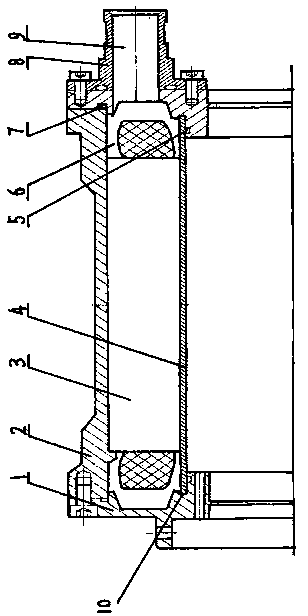

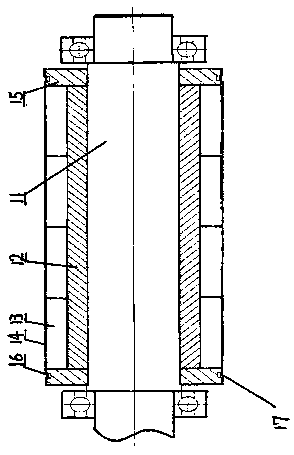

[0014] The present invention is described in detail below in conjunction with accompanying drawing:

[0015] A frame anti-compression structure of a deep-water propulsion motor, including a motor shaft 11, a frame 2, a motor end cover 1 and a stator 3, the stator 3 is arranged in the frame 2, and is fixed on the left and right ends of the frame 2 Connected to the motor end cover 1, a shielding cylinder 4 is arranged in the inner cavity of the stator 3, and an annular groove 10 is provided on the inner surface of the two motor end covers 1 outside the motor shaft, and the left end of the shielding cylinder 4 Embedded in the annular groove inside the left end cover, the right end of the shielding cylinder 4 is embedded in the annular groove inside the right end cover, the two motor end covers, the frame 2 and the shielding cylinder 4 form a closed space 6, at the right end of the motor An oil pipe adapter 8 is arranged on the cover, and the oil injection hole in the oil pipe ada...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com