An asymmetric butterfly built-in permanent magnet synchronous motor

A permanent magnet synchronous motor, butterfly-shaped technology, applied in the direction of synchronous machine, synchronous machine parts, magnetic circuit, etc., can solve the problems of low torque density, large torque ripple, etc., achieve high reluctance torque ratio, high speed The effect of low torque ripple and reducing the harmonic content of air gap magnetic density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

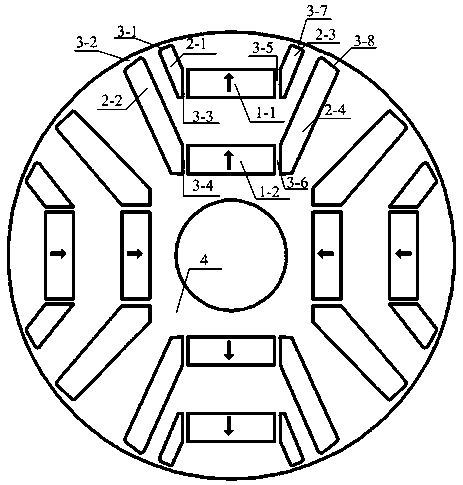

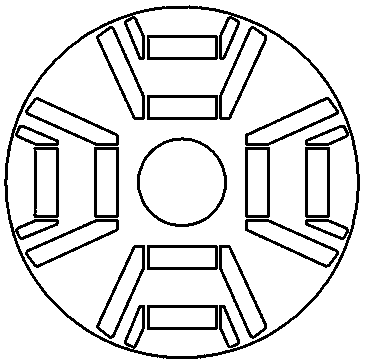

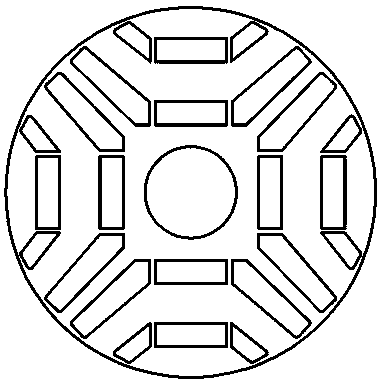

[0014] An asymmetric butterfly-shaped built-in permanent magnet synchronous motor, including double-layer permanent magnets, a magnetic isolation bridge, a magnetic isolation barrier and a rotor core, and the angles of the permanent magnet isolation magnetic barriers under different magnetic poles are designed in different shapes , that is, the structure of the magnetic isolation magnetic bridge under the same polarity is symmetrical, and the structure of the magnetic isolation magnetic bridge of the magnetic poles with different polarities is asymmetrical, which is similar to the wings of a butterfly; Short wings, the size of the magnetic barrier under the other pole is larger, which is long wings. This asymmetric shape can increase the reluctance torque without adding permanent magnets, thereby increasing the average torque output of the motor. The asymmetrical design can also reduce the harmonic content of the air gap magnetic density and effectively reduce the torque rippl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com