A hollow structure silicon-carbon composite electrode material and a preparation method thereof

A silicon-carbon composite and electrode material technology, applied in battery electrodes, structural parts, nanotechnology for materials and surface science, etc., can solve problems such as uneven carbon source coating, easy agglomeration of particles, and environmental hazards, and achieve Improve cycle stability and power performance, uniform coating, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

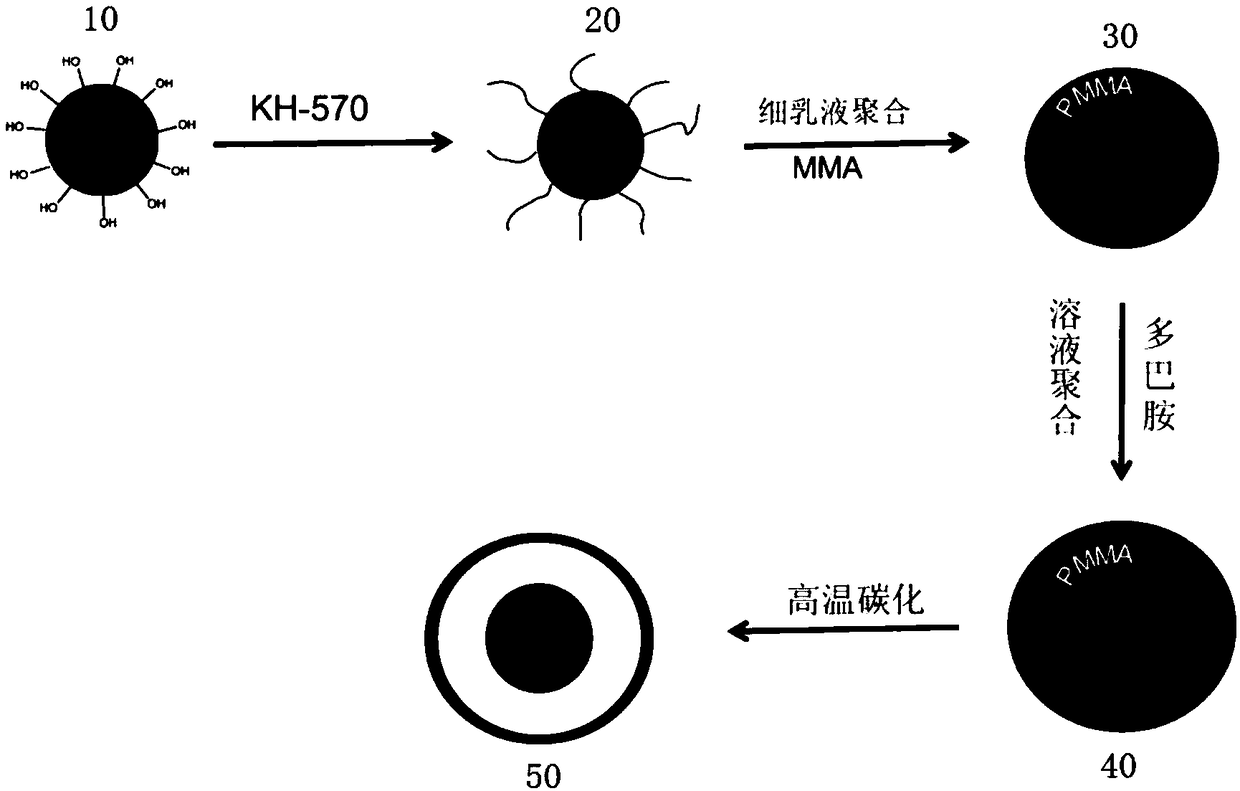

[0029] like figure 1 As shown, the preferred embodiment of the present invention discloses a method for preparing a hollow silicon-carbon composite electrode material, comprising the following steps:

[0030] S1: Disperse nano-silicon particles in an organic solvent to obtain a dispersion liquid, then add a coupling agent to the dispersion liquid and adjust the pH value to 3-4, wash and dry in sequence to obtain lipophilic modified silicon nano-particles;

[0031] Specifically, the particle size of the nano-silicon particles is 50-80nm, the organic solvent is a common organic solvent such as ethanol, and the mass of the coupling agent added is 3-10% of the mass of the nano-silicon particles. The washing process is specifically: using alcohol Washing is performed sequentially with the mixed solution and pure water whose water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com