Multi-temperature-zone refrigerator comprising work recovery pulse tube cryocooler and refrigerating method

A pulse tube refrigerator and multi-temperature zone technology, which is applied in refrigerators, household refrigerators, household refrigeration devices, etc., can solve the problem that the refrigeration function of ordinary refrigerators cannot meet the requirements of food refrigeration, and achieve high reliability and high efficiency , the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

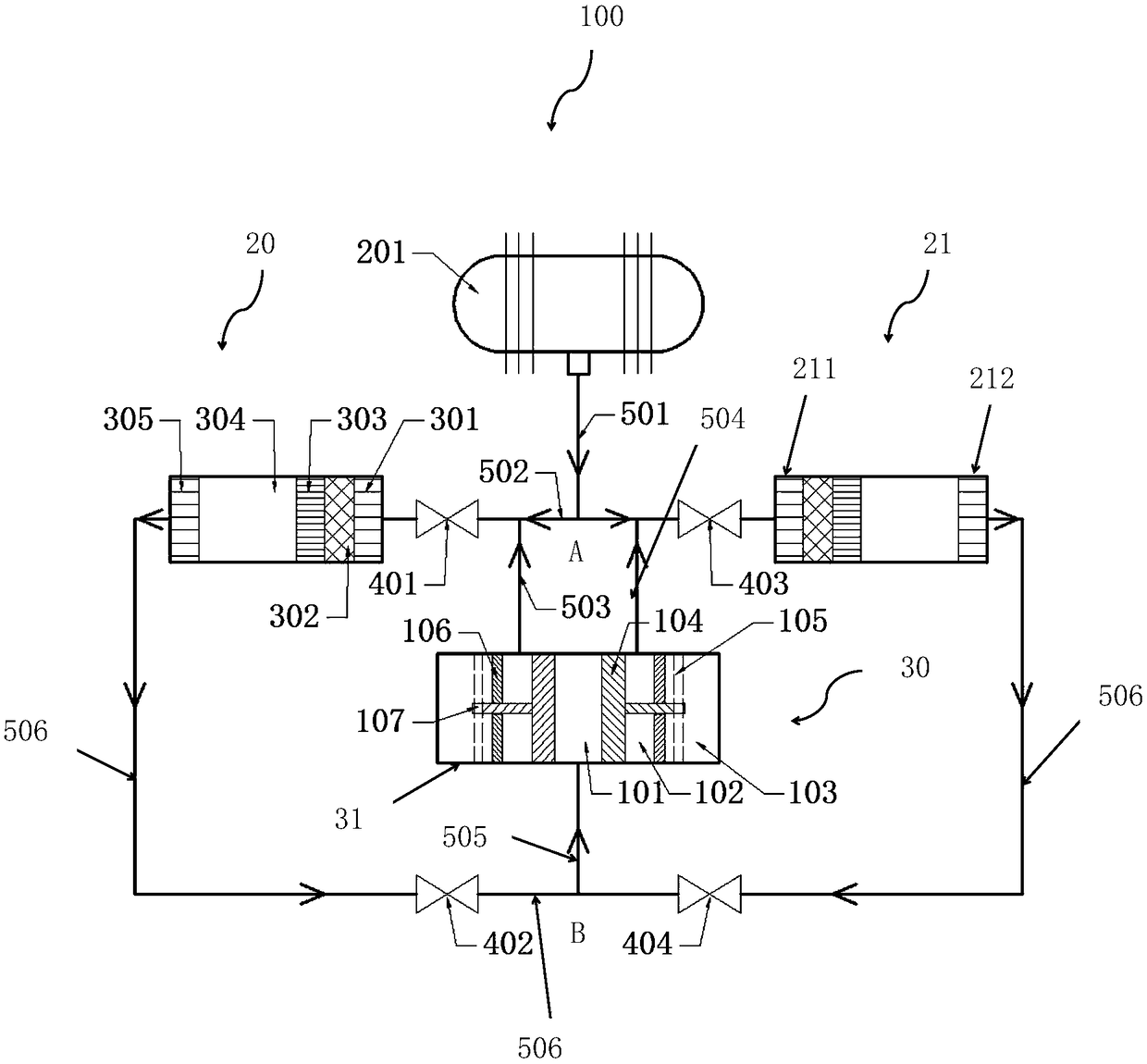

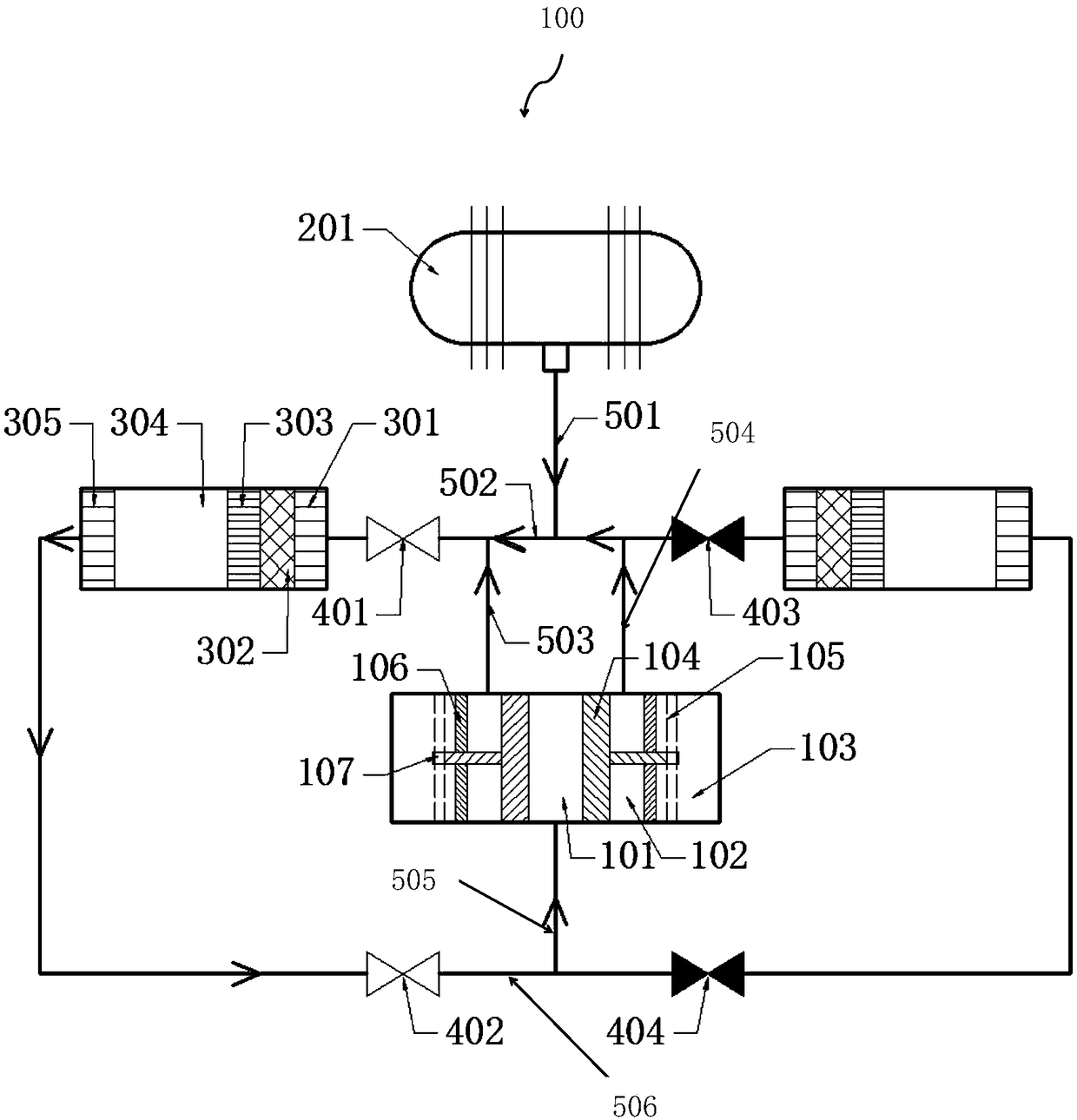

[0029] A multi-temperature zone refrigerator using a work recovery pulse tube refrigerator includes a refrigerator cabinet and a refrigeration system.

[0030] The refrigerator box has a first freezer compartment 401, a second freezer compartment and a cooling vent.

[0031] The refrigeration system includes a refrigerator part 100, a cooling part, a heat dissipation part and a control part.

[0032] The refrigerator part 100 is installed in the refrigerator box and is located on the top of the box.

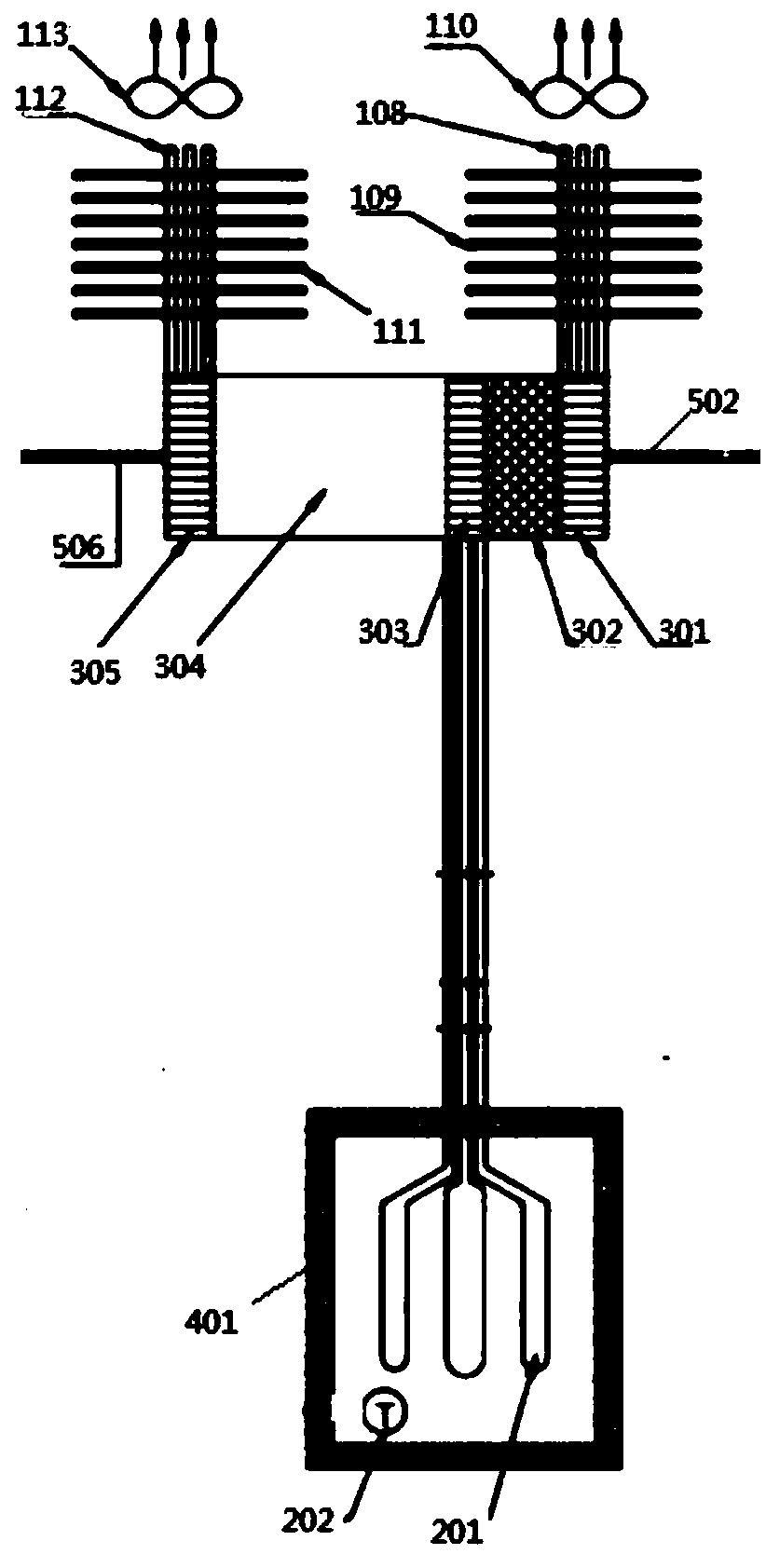

[0033] like figure 1 As shown, the refrigerator unit 100 includes an opposed compression linear compressor 201 , a first cold finger unit 20 , a second cold finger unit 21 , and a work recovery unit 30 .

[0034] The opposing compression linear compressor 201 adopts an opposing arrangement of compression pistons to ensure maximum balance of the axial force of the linear compressor and reduce vibration.

[0035] The opposite compression linear compressor 201 has a compression c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com