Vehicle universal joint outer star wheel, manufacturing process thereof and cold finishing mold

A universal joint and alien wheel technology, which is used in the manufacture of tools, wheels, vehicle parts, etc., can solve the problems of difficulty in meeting the quality requirements of auto parts, poor organization and poor compactness, and low material utilization. The effect of saving raw materials, cavity strength and impact resistance, and high internal tissue density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

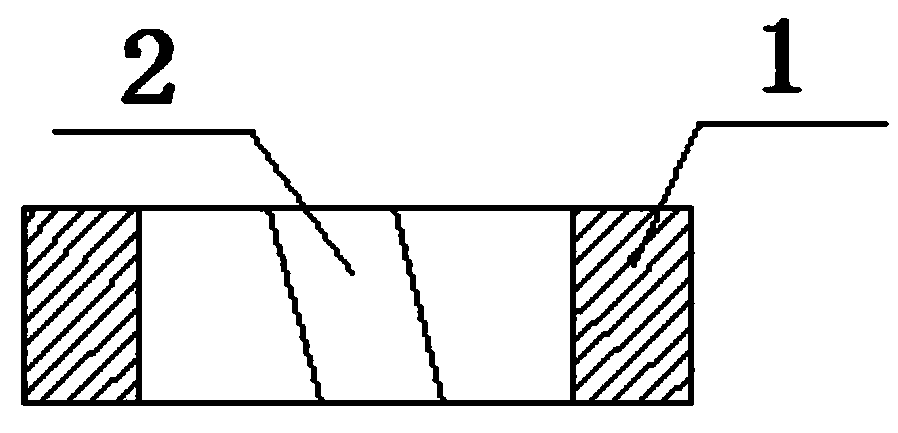

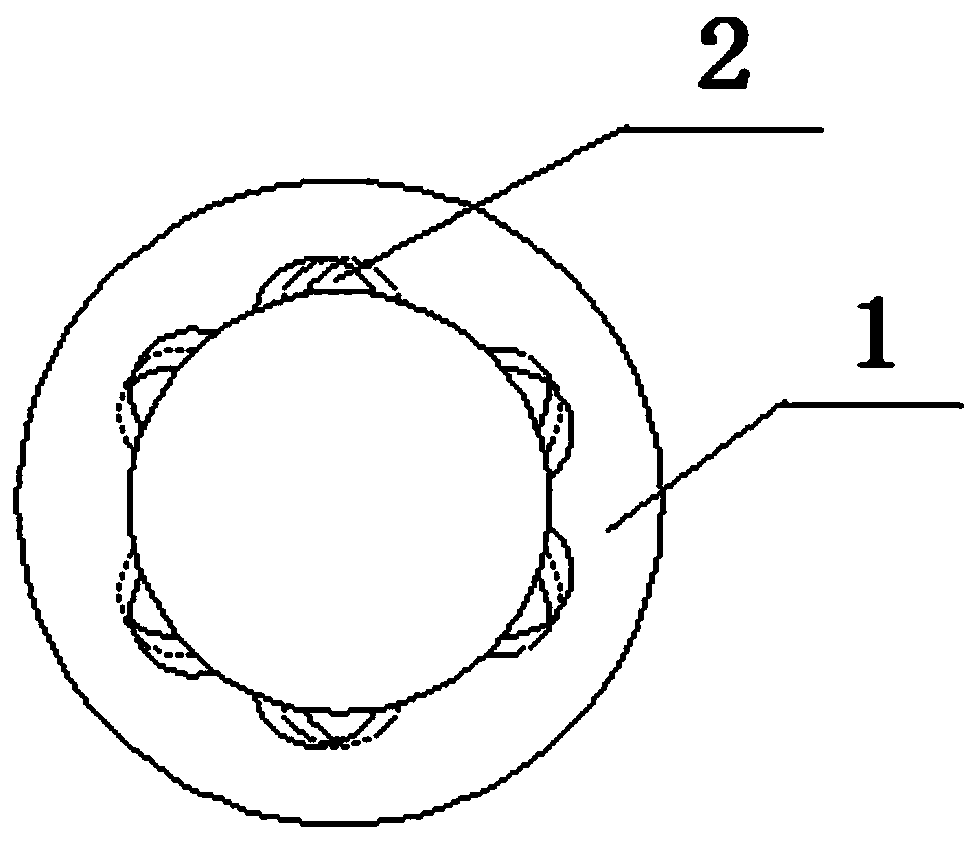

[0025] Example: see figure 1 with figure 2 As shown, a car universal joint outer planetary wheel includes a hollow cylindrical body 1, and the inner surface of the hollow cylindrical body 1 is evenly provided with six outwardly inclined ballways 2 in the circumferential direction, and the outwardly inclined ballways 2 are elliptical grooves The structure, the center line of the outer slope 2 and the axis of the outer planetary wheel form an acute angle α, two adjacent outward slopes 2 are symmetrically arranged, and the hollow cylindrical body 1 is forged from the overall structure.

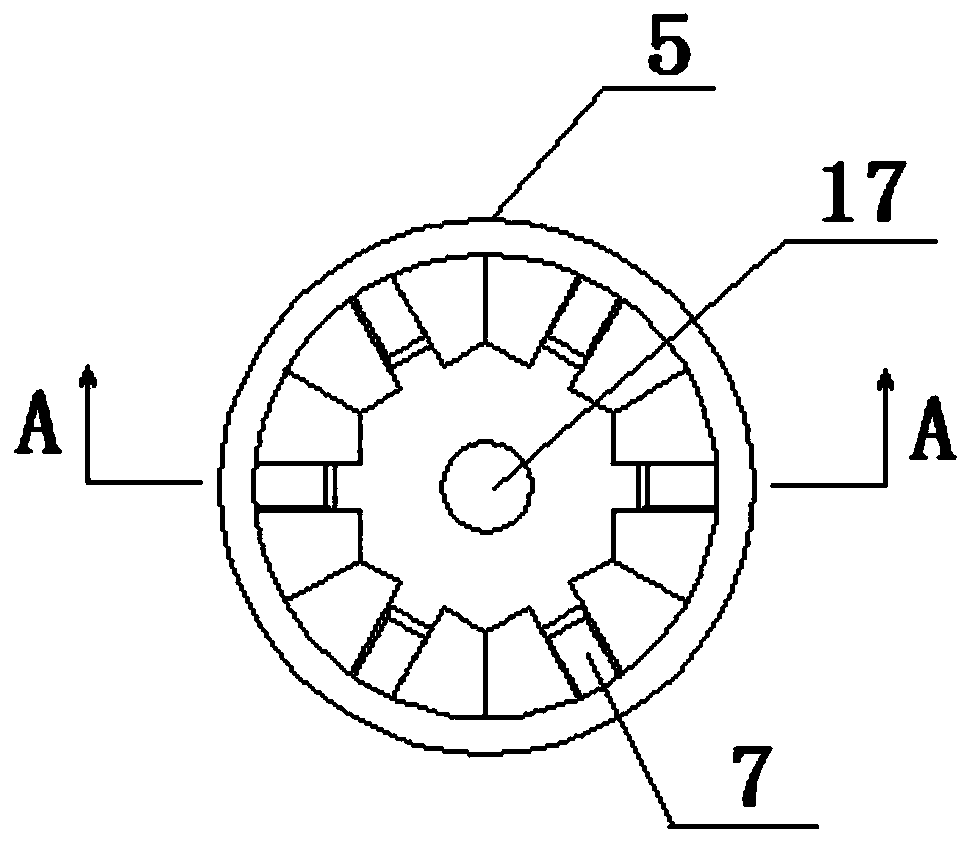

[0026] see image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, the manufacturing process includes the following steps: ① blanking, shot blasting: select the diameter of the bar, and cut the required length of the bar according to the size of the drawing; send the blank after making the blank into the shot blasting machine for sandblas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com