Cooling system capable of improving engine warming-up speed and lowering oil consumption

A technology of warm-up speed and fuel consumption, applied in the direction of engine cooling, engine starting, coolant flow control, etc., can solve the problems of increasing heat loss, incomplete combustion, increasing fuel consumption, etc., to reduce fuel consumption and emissions , The effect of fast heating oil consumption and reducing friction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

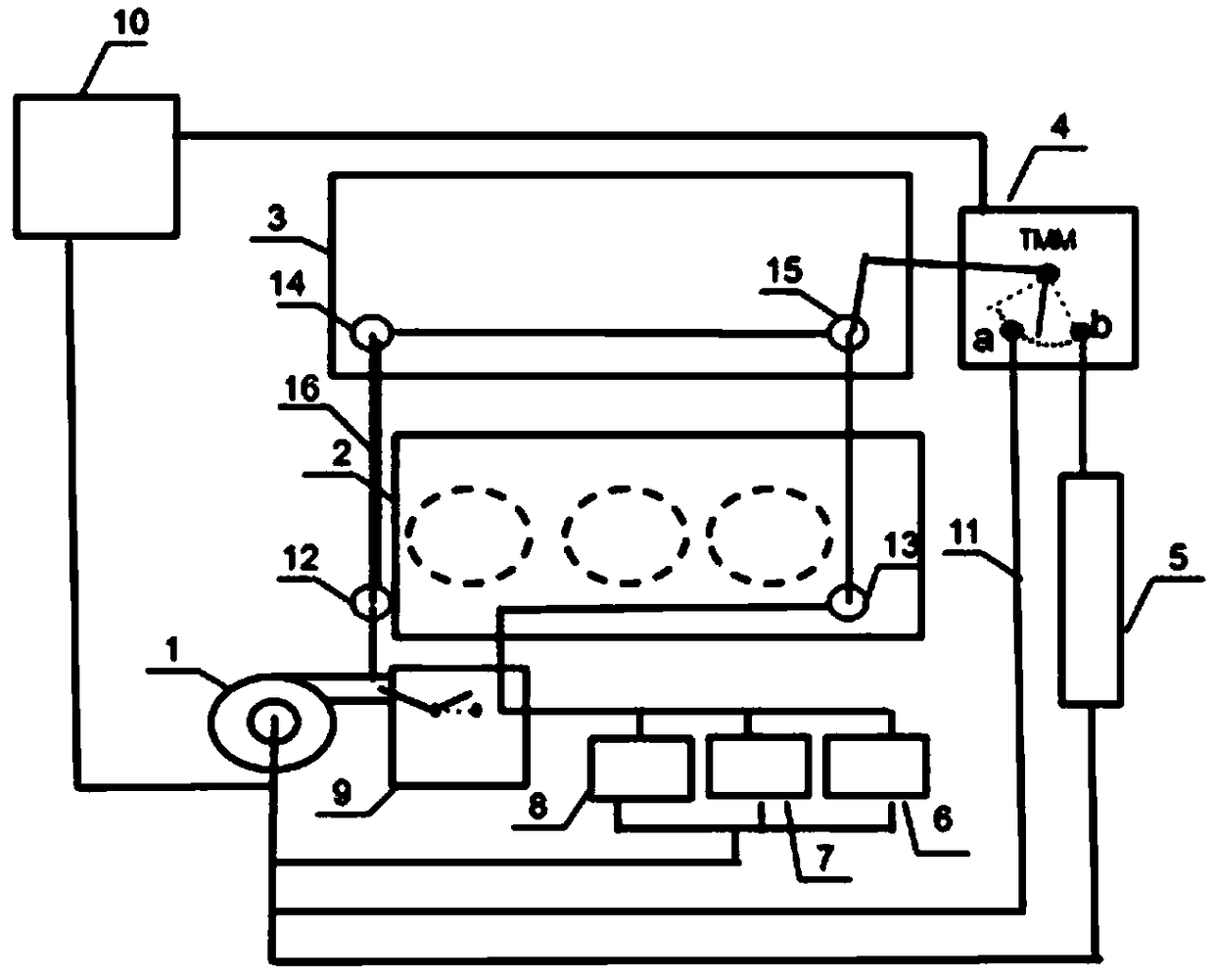

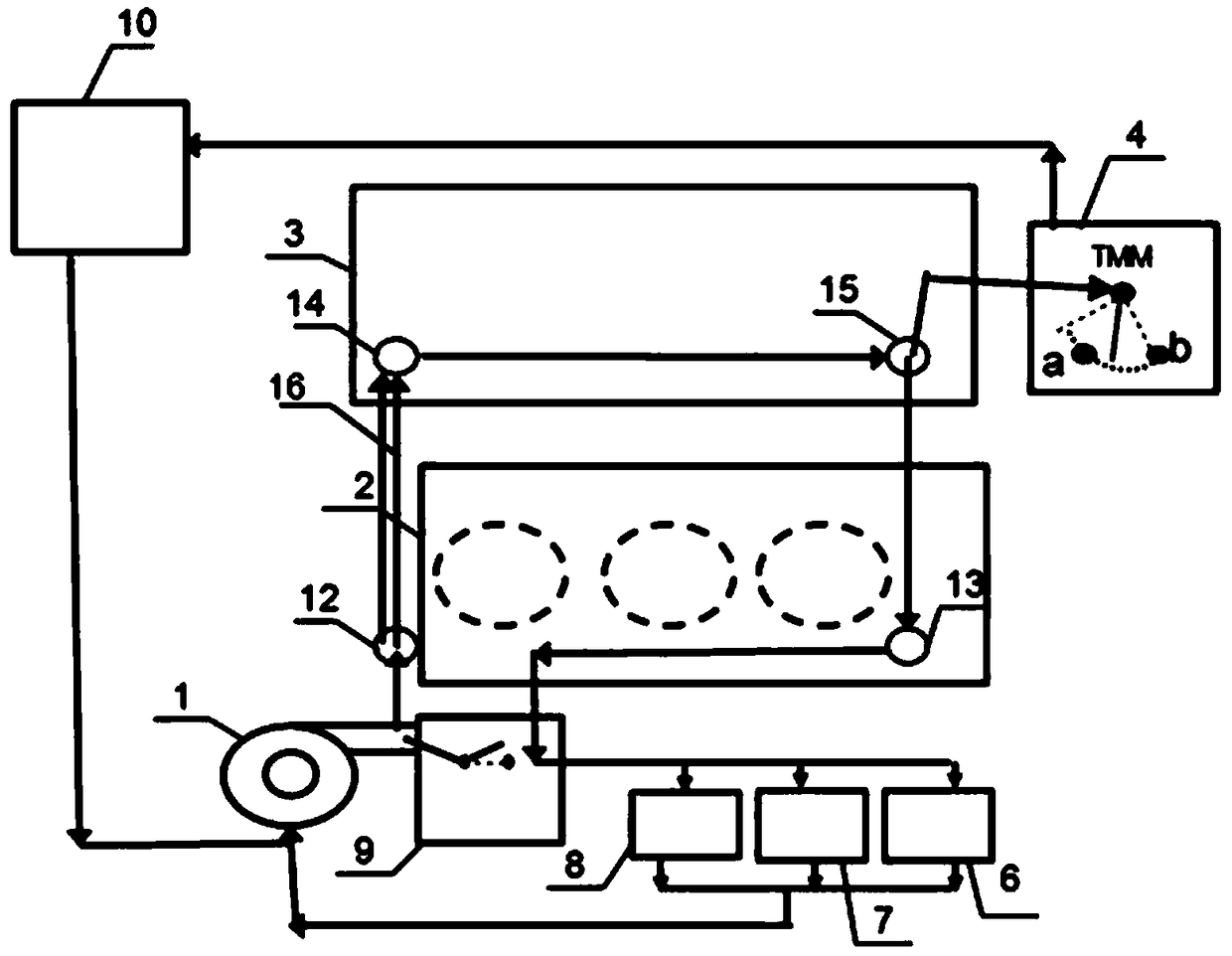

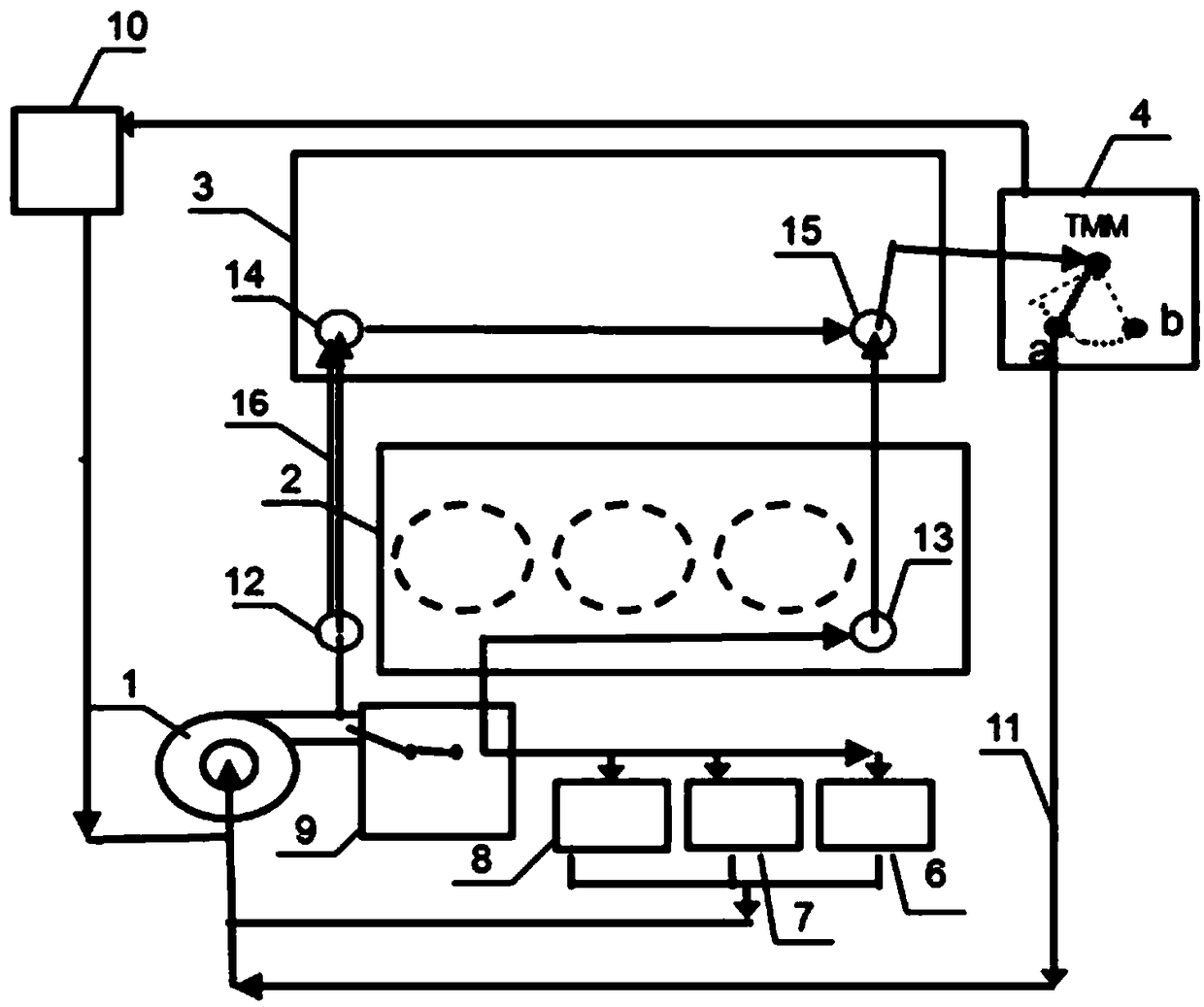

[0021] The structure of this system can be found in figure 1 , the system includes the following components: engine water pump 1, engine block, block water jacket 2, cylinder head water jacket 3, thermostat 4, radiator 5, HVAC 6, engine oil cooler 8, water storage pot 10 and solenoid valve 9.

[0022] Among them, the thermostat 4 adopts a thermal management thermostat TMM (thermal management module), which has a normally open water outlet and two switchable water outlets. Specifically, Schaeffler Audi A3 S3 or ITW Changan can be selected. Auto 1306040-B01 / B02 etc.

[0023] The solenoid valve 9 has a water inlet and two water outlets, for example, the product of Yuyao Sanye Valve Technology Co., Ltd. model 2W-200-20 can be selected.

[0024] In addition, an independent water passage 16 is set in the cylinder body, which is not connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com