Sigma-shaped cold-formed thin-walled steel section upright column skeleton system tent and producing method thereof

A cold-formed thin-walled steel and column technology, applied in tents/canopies, building types, buildings, etc., can solve problems such as poor wind resistance, small accommodation space, damage, etc., to improve bearing capacity, increase column strength, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

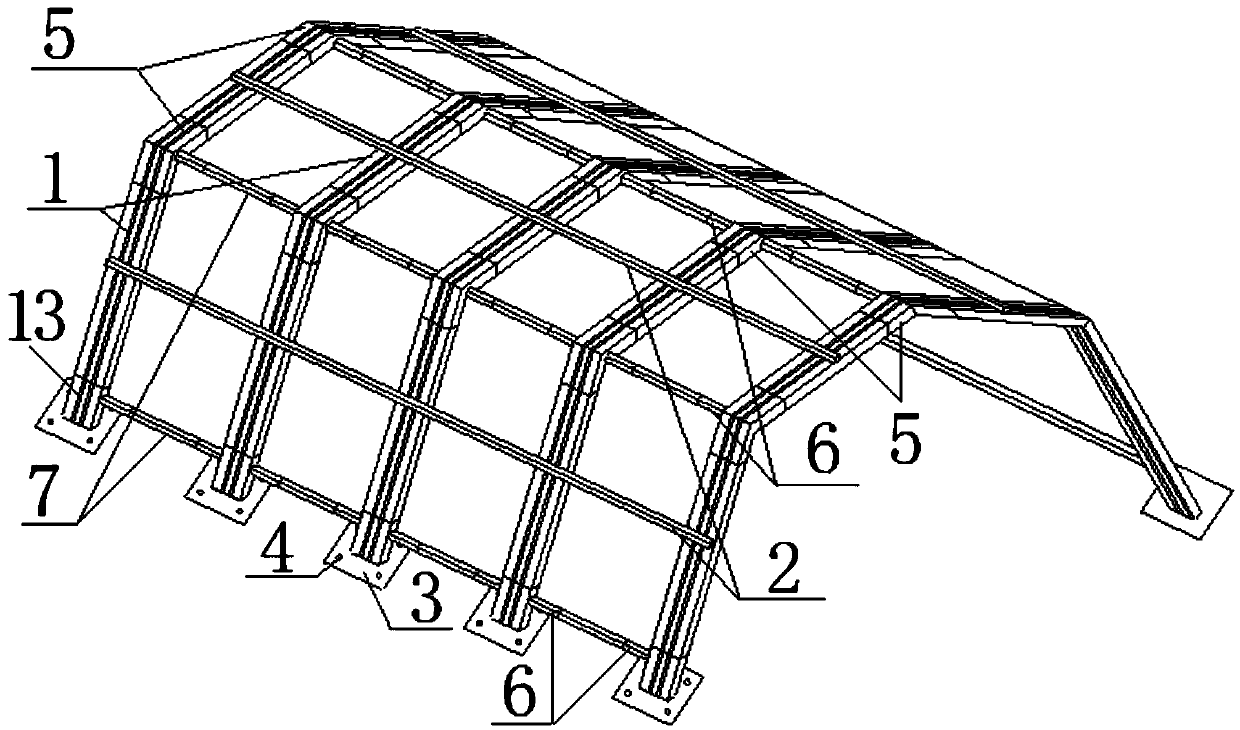

[0033] Such as Figure 1-Figure 6 As shown, the Σ-type cold-formed thin-walled steel column skeleton system tent of the present invention includes more than two vertically arranged parallel rigid frames, and the adjacent two rigid frames are connected by rectangular steel pipes 2 and short square steel pipes 7. Each rigid frame is composed of a roof rigid frame, shoulder rigid frames on both sides, and prefabricated column feet. The shoulder rigid frames are respectively installed on both sides of the roof rigid frame, and the lower ends of the shoulder rigid frames are respectively connected to the prefabricated column feet.

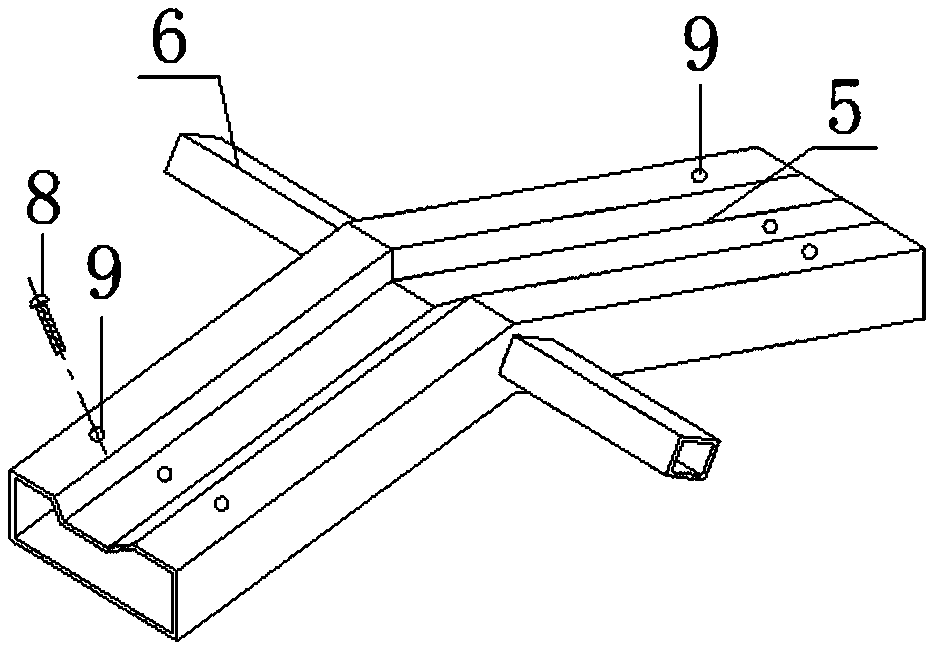

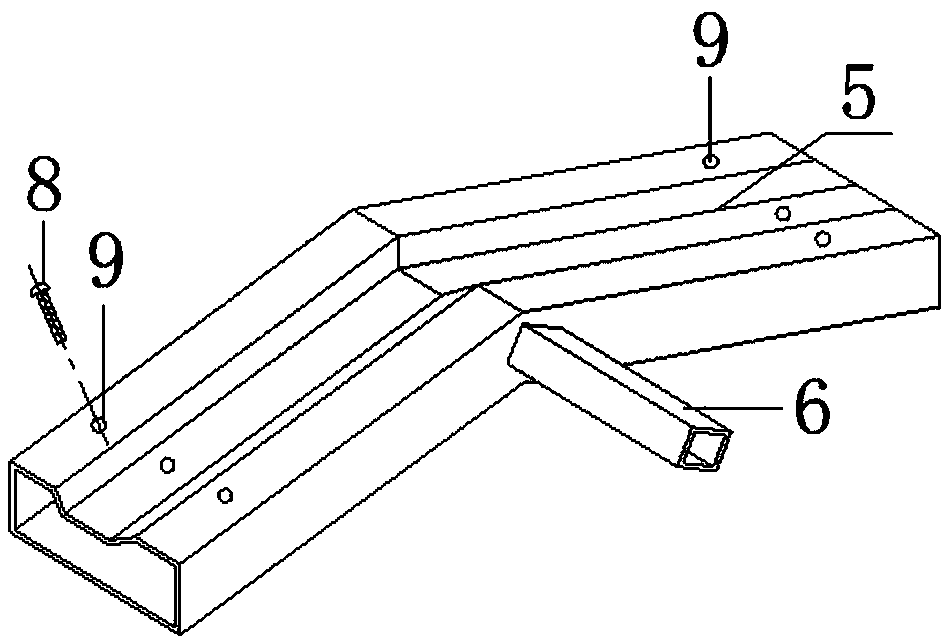

[0034] The joints of the roof rigid frame, the shoulder rigid frame on both sides, and the prefabricated column foot are directly inserted into the steel pipe connector 6 through the short square steel pipe 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com