Grouting repair construction method for underground continuous wall defect

An underground diaphragm wall and construction method technology, which is applied in basic structure engineering, basic structure repair, construction, etc., can solve the problems of rising concrete strength, high cost, dragging down the progress of the project, etc., and achieves easy on-site operation, convenient transportation and storage. , the effect of high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] The underground diaphragm wall defect grouting repair construction method of the present invention, its construction steps are:

[0020] 1) Construct water-stop curtains on both sides of the ground wall, and clean up the waste slurry and waste soil above the tank section

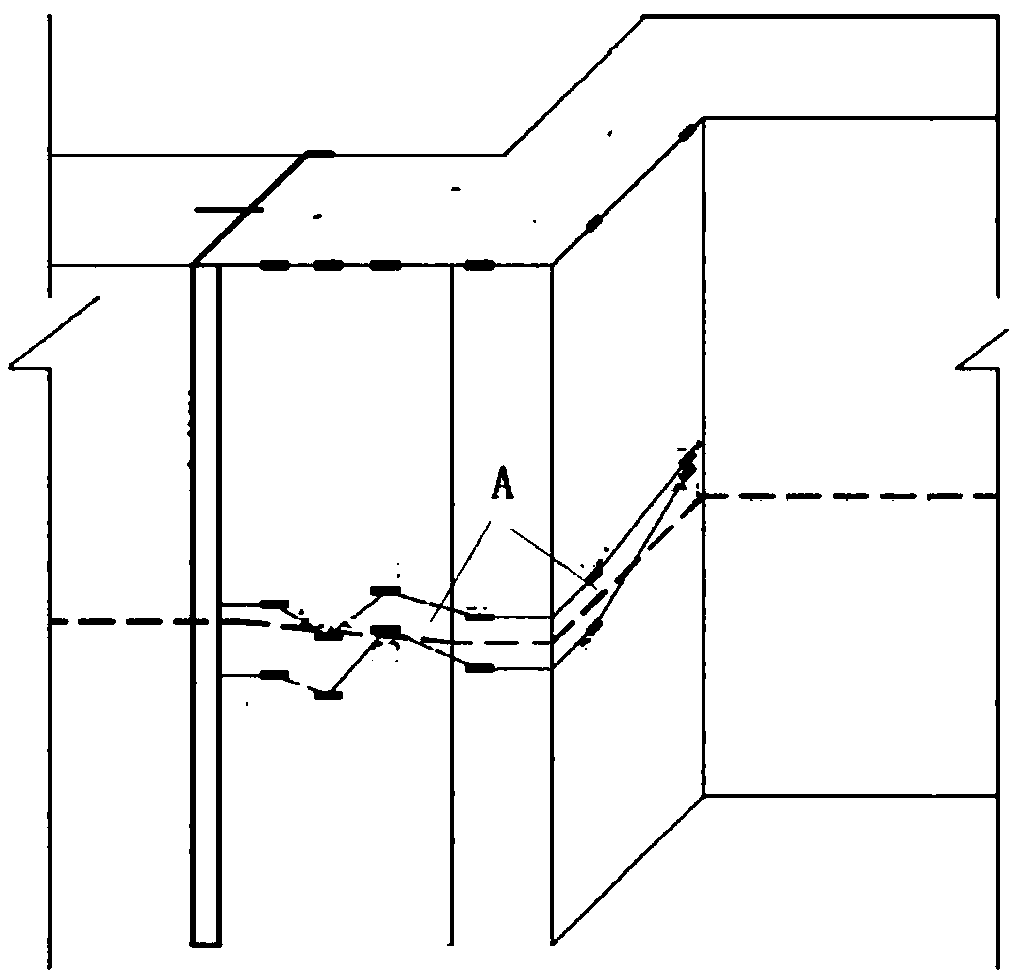

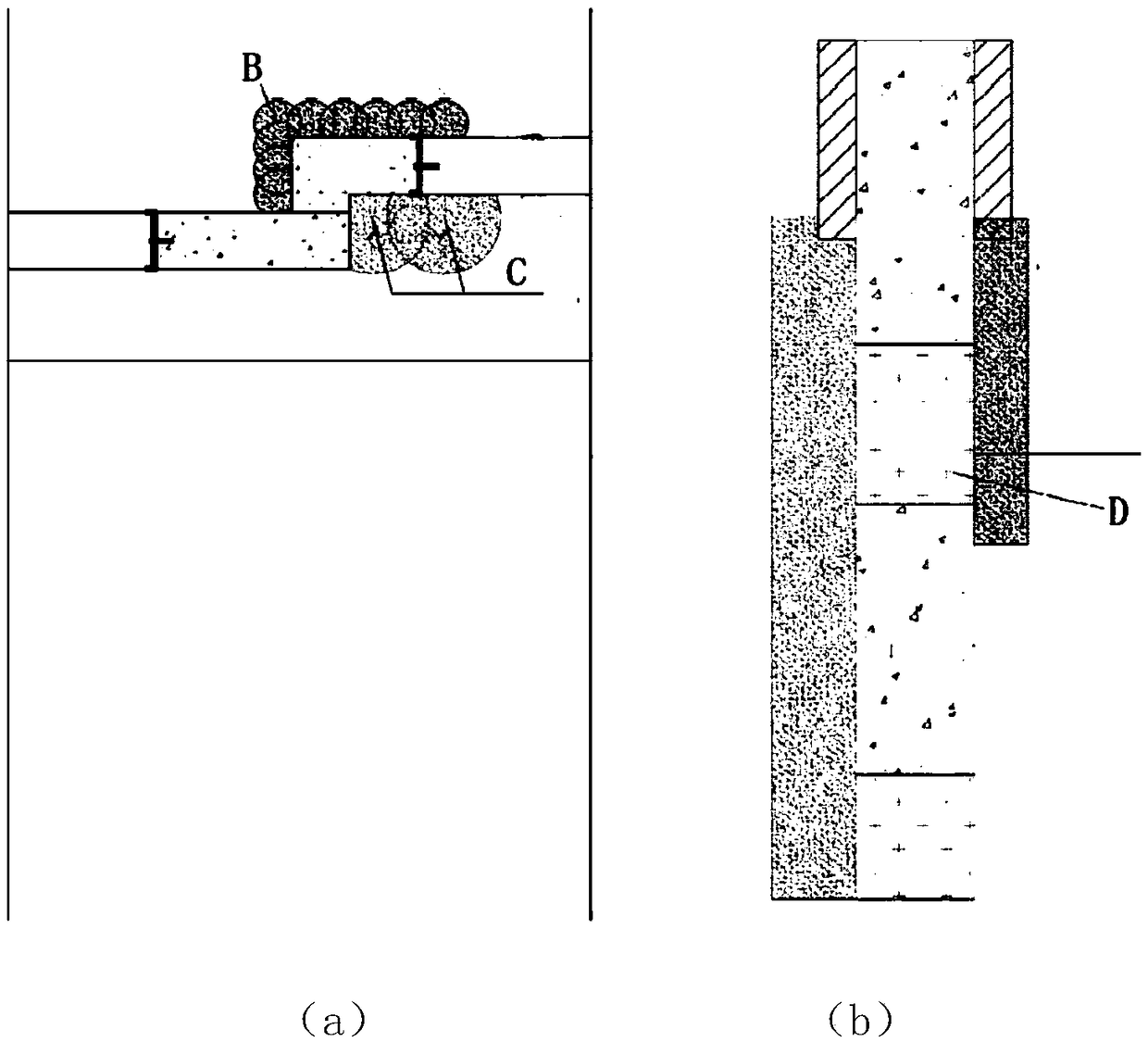

[0021] In order to prevent the grout from overflowing during the grouting process, first place the ground wall defect position A (see figure 1 ) construction of water-stop curtains on both sides, such as figure 2 As shown in (a) and (b), the conventional rotary spraying reinforcement B or MJS method can be used to reinforce C, so as to ensure the repair effect. In order to ensure that the defect location can be accurately located in the ground wall repair operation, the waste slurry and waste soil generated in the above process should be cleaned up first.

[0022] 2) Take t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com