Continuous beam bridge pier temporary consolidation structure and construction method

A temporary consolidation and pier technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as large differences in settlement, large settlement of flexible temporary bearings, and unloading reliability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0122] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

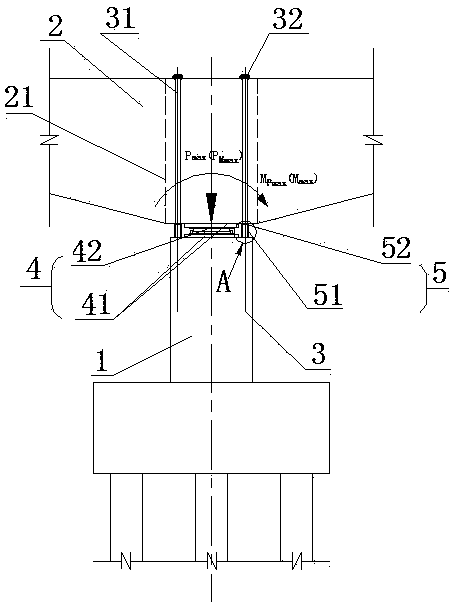

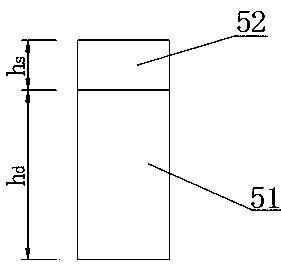

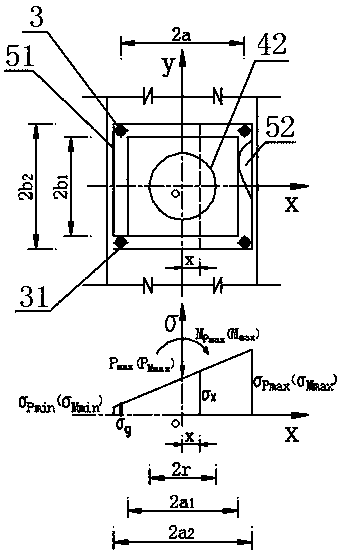

[0123] Such as Figure 1~Figure 3 As shown, 1. Bridge pier, 2. Continuous beam, 21.0 block, 3. Anchor steel bar, 31. Reserved hole, 32. Bolt, 4. Spherical support, 41. Support steel plate, 42. Support body, 5. Temporary support, 51. Spacer, 52. Tetrafluoro board.

[0124] Continuous girder bridge pier temporary consolidation structure and construction method, such as figure 1 As shown, it involves a bridge construction field, and its structure is mainly composed of a bridge pier 1 and a concrete continuous beam No. There are multiple spherical bearings 4 and temporary bearings 5 surrounding each spherical bearing between the number blocks 21, and there are also anchors anchored in the pier 1 and extending upward through temporary bearings 5 to 0. A plurality of anchoring steel bars 3 at the top of the block 21.

[0125] Wherein, each spherical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com