Zinc electrolysis negative plate scrubbing unit

A cathode plate, zinc electrolysis technology, applied in electrolysis components, electrolysis process, photography process, etc., can solve the problems that the brushing effect is not as ideal as wet brushing, increase the cost of enterprises, and the opening of the brush wheel is not adjustable, and achieve better brushing effect. , the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0059] The zinc electrolysis cathode plate brushing unit combines the horizontal plate feeding method to achieve precise positioning of the cathode plate, synchronous splints, and fast brushing of the plates, and the scrubbing effect is better.

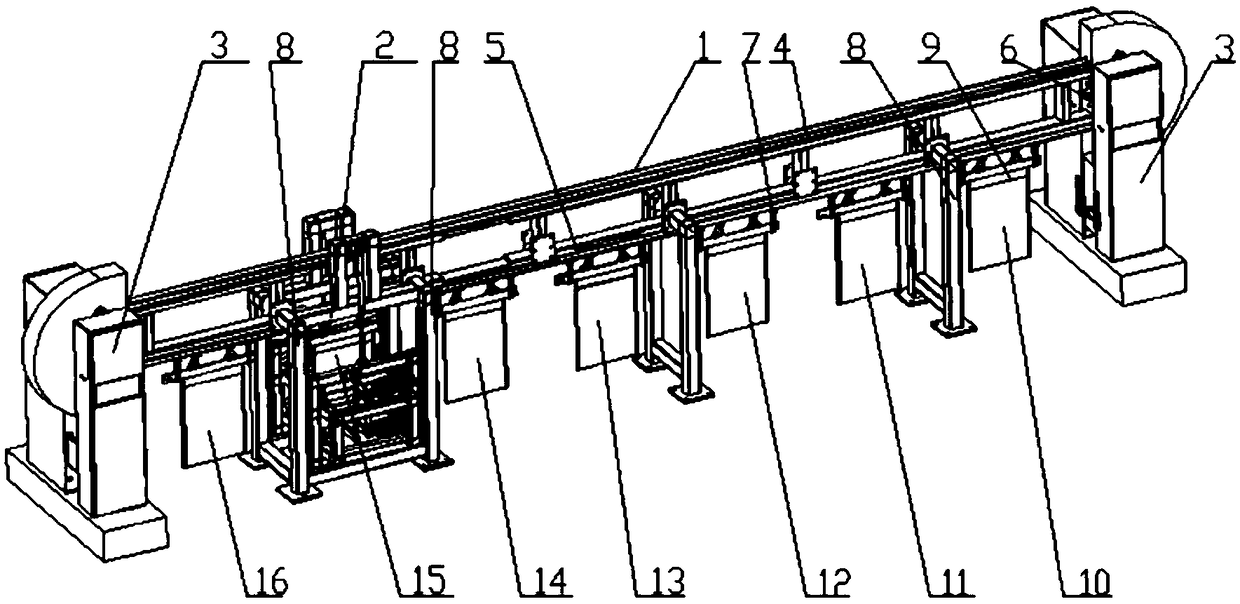

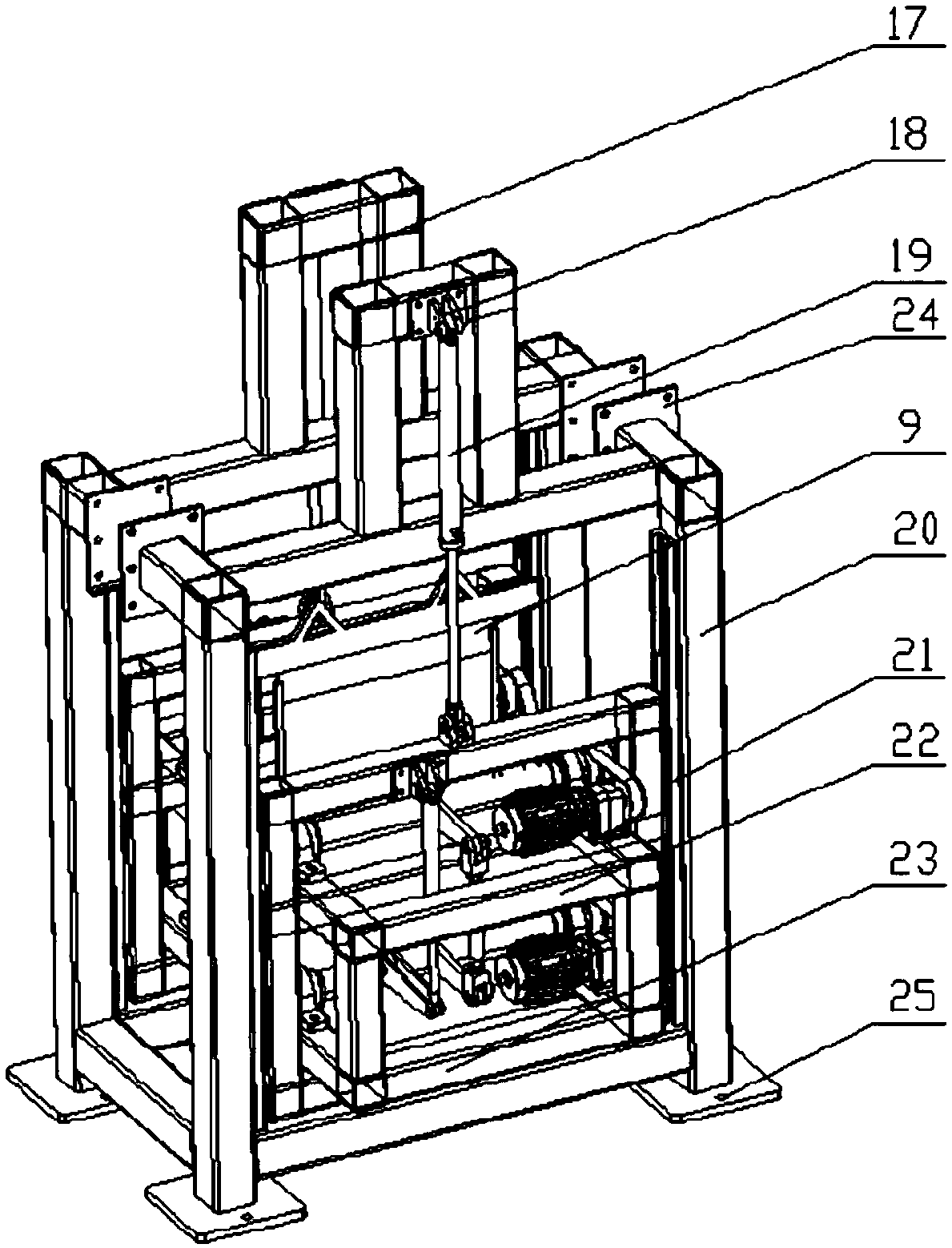

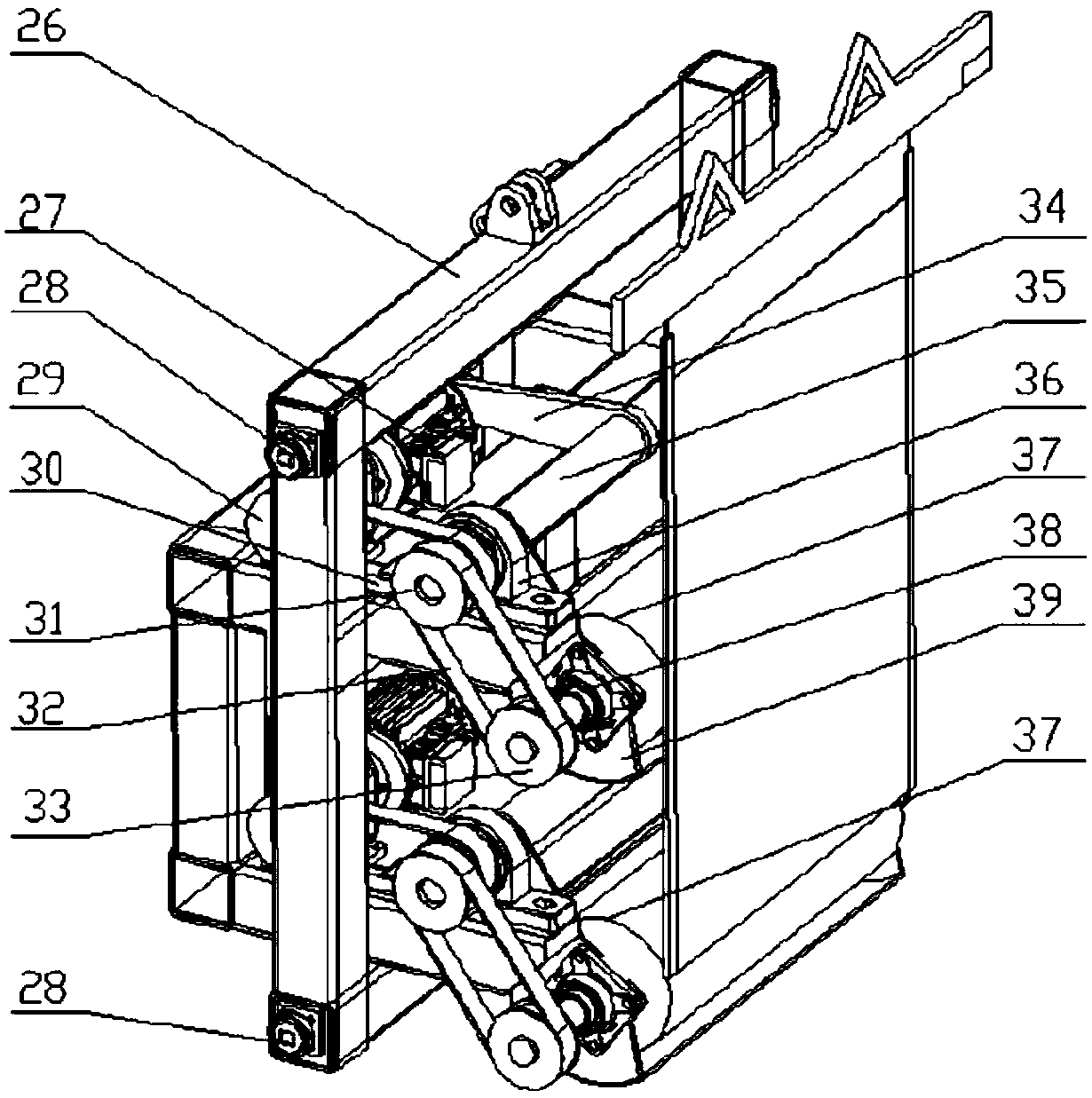

[0060] like figure 1 Shown is the structural diagram of a new type of high-efficiency cathode plate brushing unit.

[0061] The scrubbing unit of the present invention includes: a horizontally moving plate transfer system 1 and a plate brushing machine 2 .

[0062] The horizontal plate transfer system 1 includes: a drive head 3 , a chain support upper beam 4 , a chain support lower beam 5 , a sprocket chain assembly 6 , a cathode plate hook 7 , a support vertical beam 8 , and a cathode plate 9 .

[0063] The operation process of the horizontal plate transfer system is as follows: the cathode plate 9 is placed on the cathode plate hook 7 of the input station 10, the driving head 3 drives the sprocket chain assembly to step a certain d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com