Plier-shaped shoe washing brush

A shoe-washing brush, pincer-shaped technology, applied in the direction of brushes, bristles, bristle brackets, etc., to reduce labor intensity, reduce wear, and increase the area of brushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

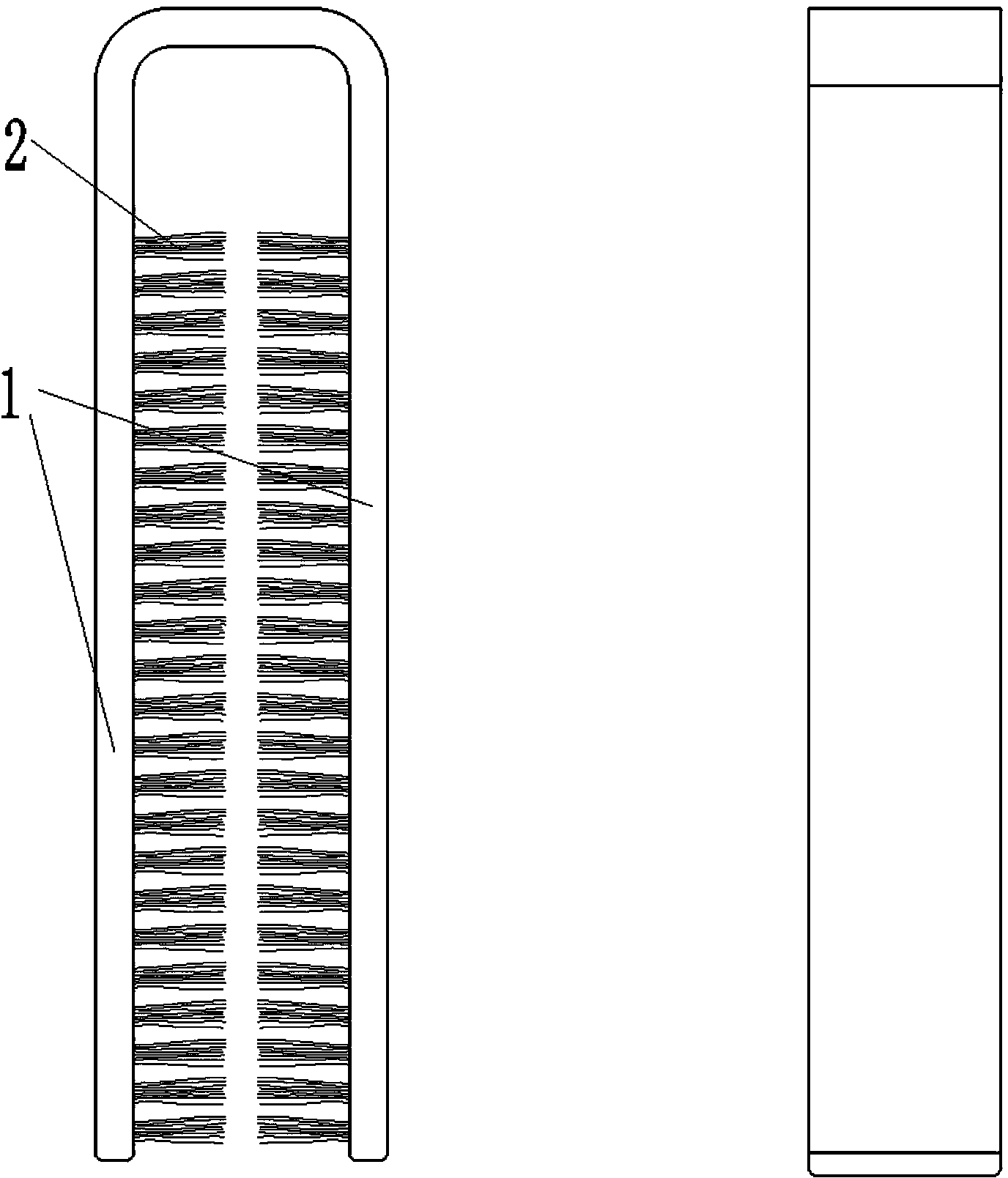

[0025] Embodiment 1: as shown in the accompanying drawings of the description figure 1 , The pincer-shaped shoe washing brush is composed of (1) brush plate and (2) bristles, the upper ends of the two (1) brush plates are directly connected, and the lower ends are open to form a pincer shape, with (2) bristles inside the pincer shape. This embodiment can be produced by one-time molding and then hair-planting. It can also be bent into pincers and then hair-planted by strip materials. It can also be bent or processed after multiple parts are planted and then welded, glued, screwed, riveted. and other ways to reduce the difficulty of hair transplantation. This structure has the characteristics of low production cost and good durability. When using the upper part of the pliers-shaped shoe washing brush, the clamping force can be provided by the elastic force of the brush plate and the connection, and a greater clamping force can be applied to increase the clamping force. force. ...

Embodiment 2

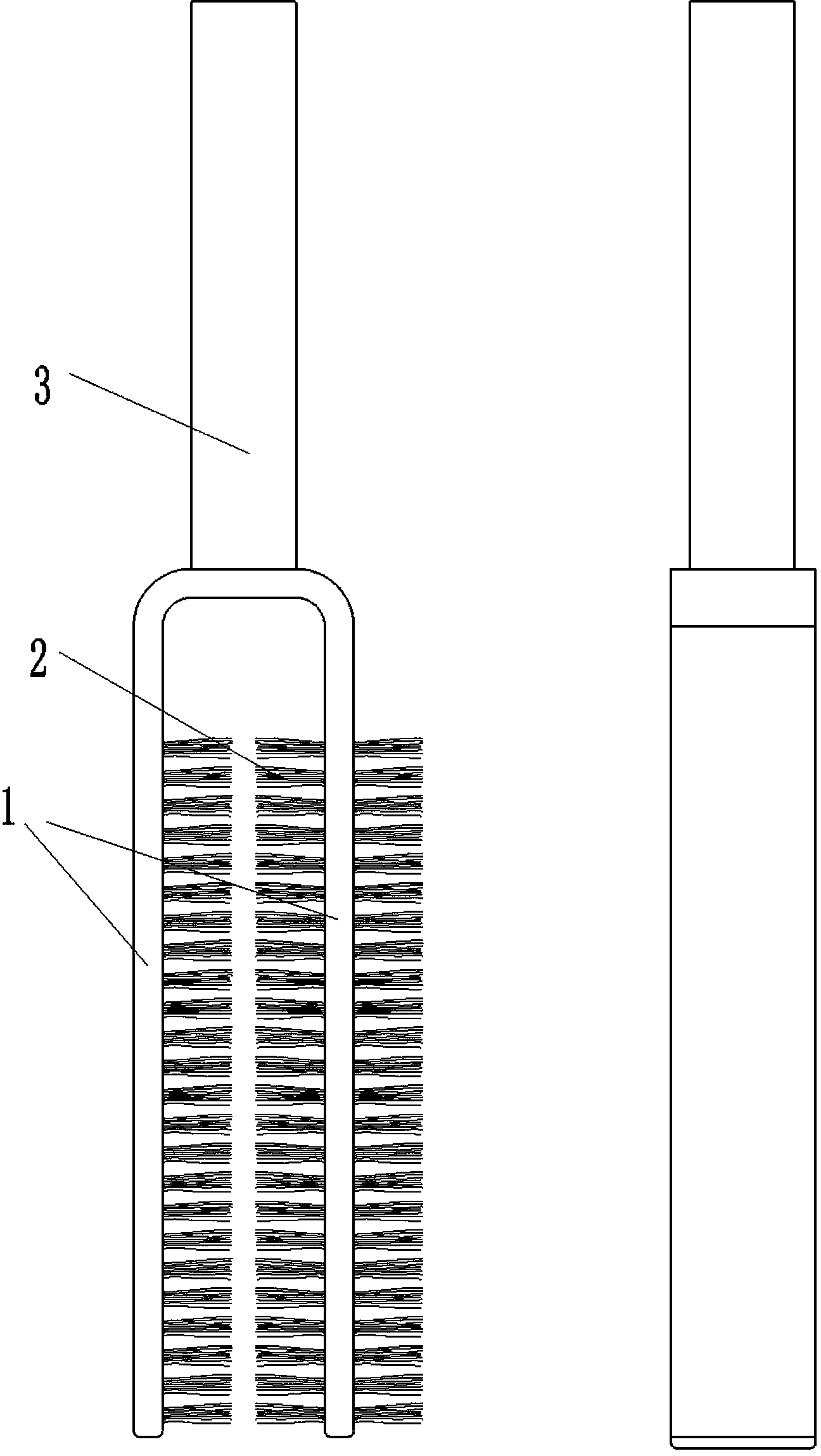

[0026] Embodiment 2: As shown in the accompanying drawings of the description figure 2 , The pliers-shaped shoe washing brush is composed of (1) brush plate, (2) bristles, and (3) handle. The upper ends of two (1) brush boards are directly connected, and the lower ends are open to form a pincer shape. There are (2) bristles on the inside of the pincer shape, and there are also bristles on one of the outer sides. The product can be produced by one-time molding and then wool-planting, or it can be injection-molded first, then wool-planted, and then bent, or processed into multiple parts, then wool-planted, and then connected by melting, gluing, threading, riveting, etc. to reduce the difficulty of wool planting. When in use, hold the handle with your hand, and the elastic force of the brush plate and the joint can provide a clamping force, and the outer bristles can be used to scrub the sole and the toe of the shoe. This structure has the characteristics of lower production co...

Embodiment 3

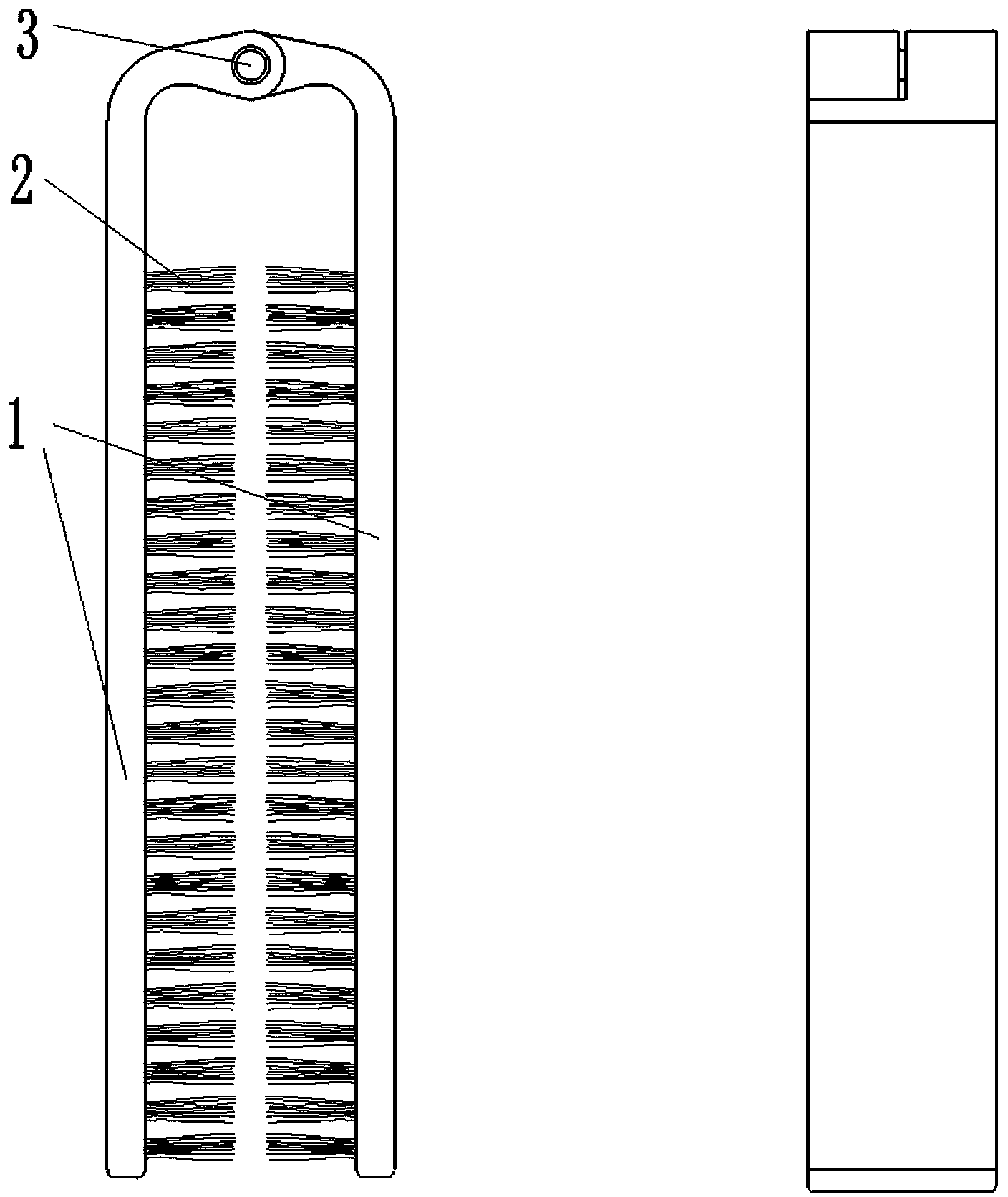

[0027] Embodiment three: as shown in the accompanying drawings of the description image 3 , The pincer-shaped shoe washing brush uses (3) hinge shafts to connect the upper ends of two (1) brush plates to form a pincer shape, and has (2) bristles inside the pincer shape. When in use, hold the upper part of the pliers-shaped shoe-washing brush, which can provide clamping force by the grip of the hand. After the two brush plates are opened, the bristles originally located on the inner side can be used to scrub the sole and toe of the shoe. This structure has the characteristics of lower production cost, better durability, and can be changed flexibly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com