Drying and impurity-removing machine for root of red-rooted salvia

A technology of drying and drying Danshen, which is applied in the direction of drying machine, drying gas arrangement, drying, etc., can solve the problems of damage to Danshen plants, low efficiency, etc., and achieve the effects of scientific research, rapid scrubbing and drying, and integrity assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

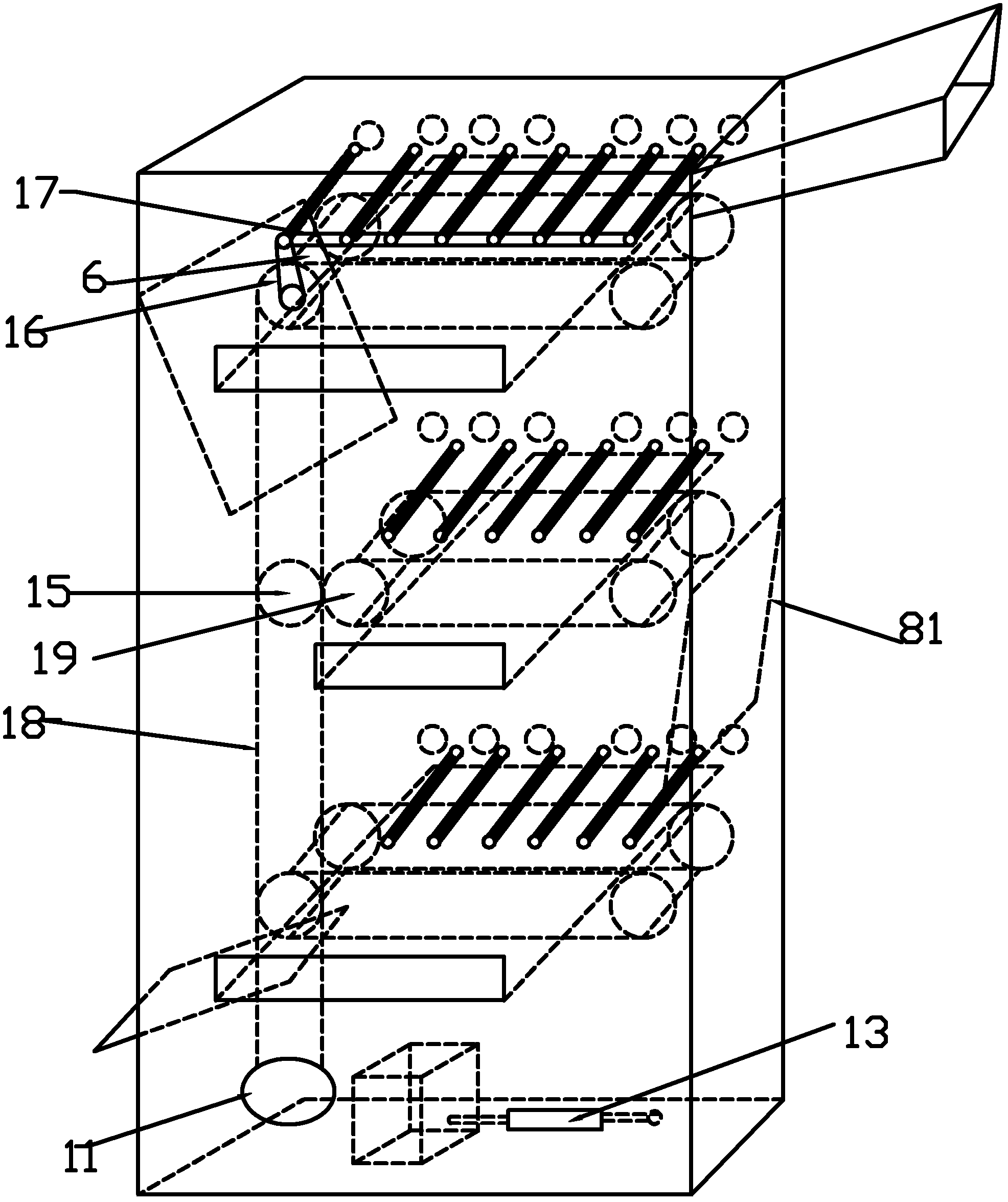

[0010] Such as figure 1 shown. A Danshen drying and impurity removal machine comprises a box body 1, and the outer wall of the box is provided with a material inlet 2, a blower port 4, a material outlet 10, a dust outlet 9 and other parts.

[0011] Inside the cabinet 1, there are upper, middle and lower three-layer conveying mesh belts 6, and each layer of conveying mesh belts is supported on the two side walls of the cabinet by the drive rollers 5 at both ends, and the shaft end of one of the drive rollers is provided with a drive roller The drive sprocket is driven by a motor to make each conveyor belt rotate in a specified direction. A row of brush rollers 3 are arranged above each conveying mesh belt, and the two ends of the brush rollers are supported on the two side walls of the box body, and a brush roller chain matched with the brush roller drive chain 17 is arranged on the same side of the brush rollers. wheel. When the brush roller sprocket wheel rotated, under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com