Low-smell composition of automobile seat electric slide rail lubricating grease and preparation method thereof

A car seat and composition technology, applied in the field of lubricating grease, can solve the problems of VOC, slow lifting speed, excessive content of toxic and harmful substances, etc., and achieve good antirust performance, good long life, and excellent high and low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

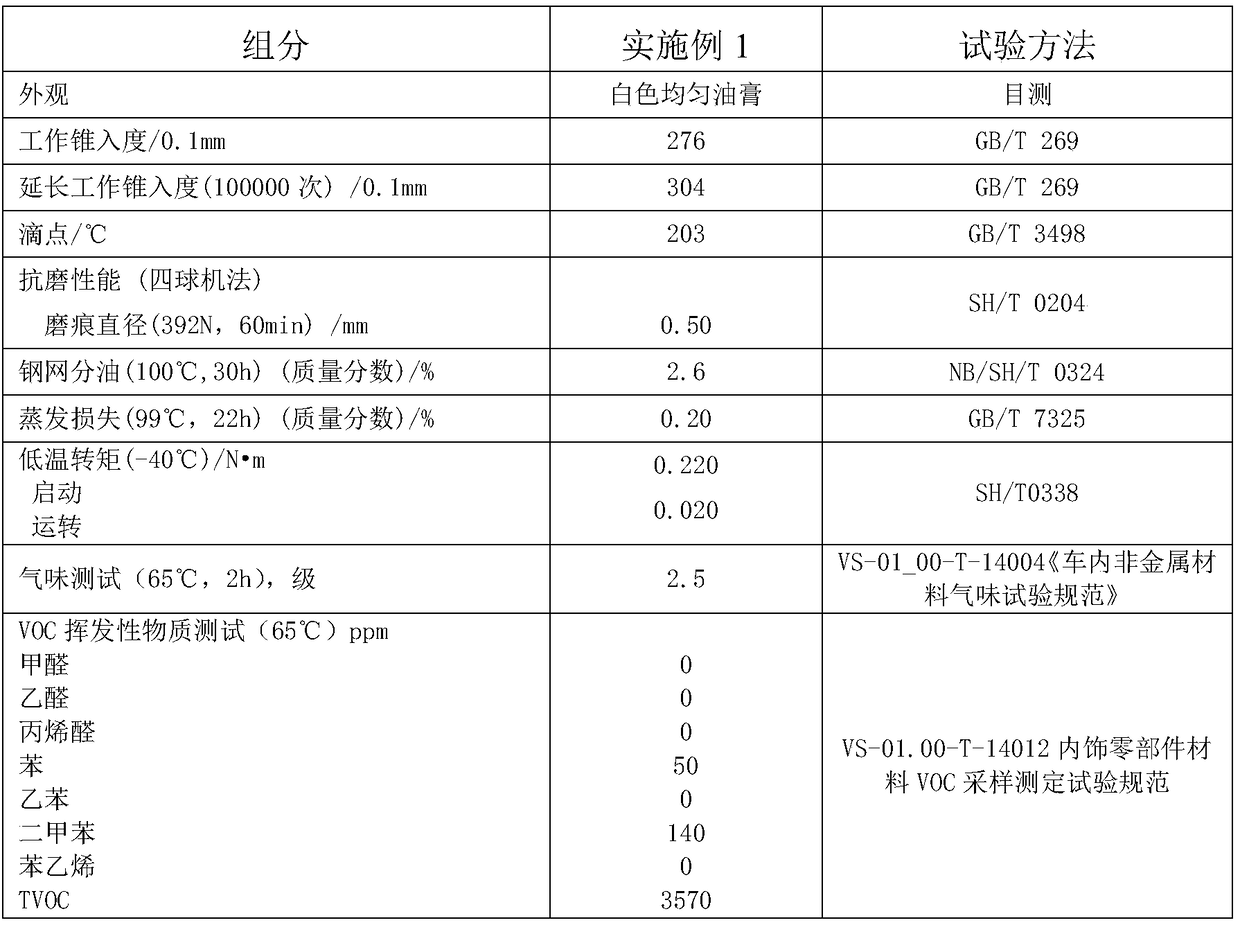

Embodiment 1

[0036] base oil 60%,

[0037] Thickener 40%,

[0038] According to the total amount of the above two components, add the following additive mass percentages:

[0039] Structure improver 0.5%,

[0040] Antioxidant 0.5%,

[0041] Rust inhibitor 0.5%;

[0042] Add 1200g of poly-a-olefin synthetic oil, 160g of lauryl hydroxystearic acid and 10g of glycerin into the reaction kettle, start stirring, heat to 85°C, add 22.2g of lithium hydroxide aqueous solution, and react under these conditions for 120 minutes; the reaction is over Finally, add 640g of polytetrafluoroethylene, heat to 160°C for secondary reaction, and control the reaction time at 30 minutes; after the reaction, raise the temperature to 202°C, keep the temperature for 2 minutes and then cool naturally, so that the temperature of the material is controlled at 165°C In between, keep the temperature constant for 30 minutes; after the constant temperature is over, stop the heat medium, cool naturally to 98°C, add 10g ...

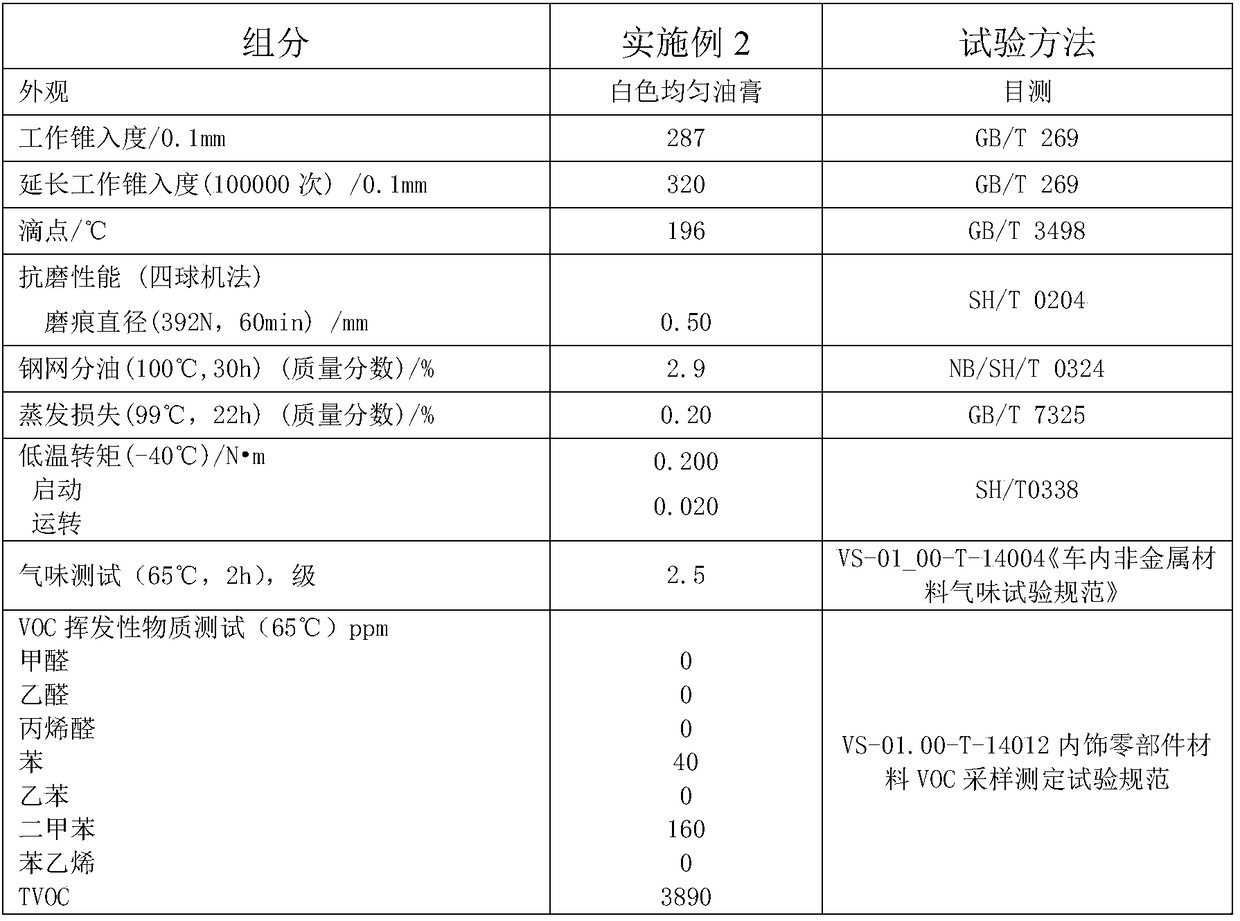

Embodiment 2

[0047] base oil 65%,

[0048] Thickener 35%,

[0049] According to the total amount of the above two components, add the following additive mass percentages:

[0050] Structure improver 0.5%,

[0051]Antioxidant 0.5%,

[0052] Rust inhibitor 0.5%;

[0053] Add 1300g of poly-a-olefin synthetic oil, 140g of lauryl hydroxystearic acid and 10g of glycerin into the reaction kettle, start stirring, heat to 85°C, add 20g of lithium hydroxide aqueous solution, and react under these conditions for 120 minutes; , add 560g polytetrafluoroethylene, heat to 160°C for secondary reaction, control the reaction time at 30 minutes; Keep the temperature constant for 30 minutes; after the constant temperature is over, stop the heat medium, cool naturally to 98°C, add 10g of anti-rust agent dodecenyl succinate; when the temperature drops to 43°C, add 10g of antioxidant 2,6-di tert-butyl-p-cresol, stirred for 40 minutes; after the stirring, the reaction material was oiled through a three-roll ...

Embodiment 3

[0058] base oil 62%,

[0059] Thickener 38%,

[0060] According to the total amount of the above two components, add the following additive mass percentages:

[0061] Structure improver 0.5%,

[0062] Antioxidant 0.5%,

[0063] Rust inhibitor 0.5%;

[0064] Add 1240g of poly-a-olefin synthetic oil, 152g of lauryl hydroxystearic acid and 10g of glycerin into the reaction kettle, start stirring, heat to 85°C, add 21g of lithium hydroxide aqueous solution, and react under these conditions for 120 minutes; , add 608g polytetrafluoroethylene, heat to 160°C for secondary reaction, the reaction time is controlled within 30 minutes; Keep the temperature constant for 30 minutes; after the constant temperature is over, stop the heat medium, cool naturally to 98°C, add 10g of anti-rust agent dodecenyl succinate; when the temperature drops to 43°C, add 10g of antioxidant 2,6-di tert-butyl-p-cresol, stirred for 40 minutes; after the stirring, the reaction material was oiled through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com