Preparation method of infrared absorption material and coating capable of being used for infrared stealth

A technology of absorbing materials and infrared rays, applied in radiation-absorbing coatings, chemical instruments and methods, polyurea/polyurethane coatings, etc., can solve the problems of inconvenient operation and pollution of solvent-based coatings, and achieve uniform distribution, broad application prospects, and resistance The effect of suppressing the transition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

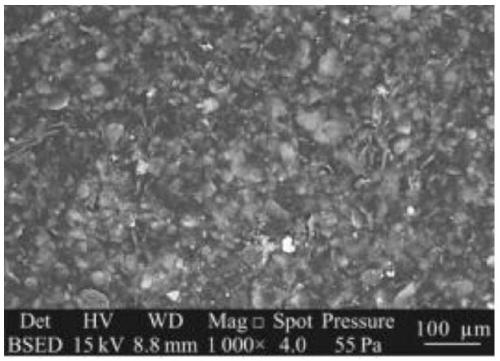

Image

Examples

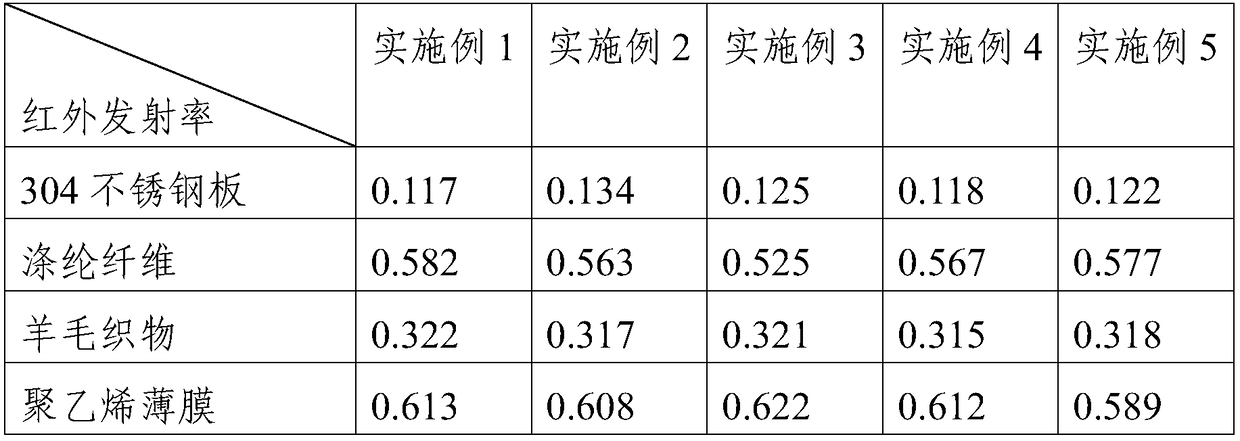

Embodiment 1

[0033] A method for preparing an infrared absorbing material, specifically: adding 16.82 g of samarium nitrate and 2.25 g of glycine into a container, then adding 400 ml of distilled water and 2 g of SRE-4010-100, ultrasonically dispersed for 45 minutes, and then adding a mass concentration of 30% 20ml of yttrium nitrate aqueous solution, continue to ultrasonically disperse for 50min, add 10ml of concentrated ammonia water drop by drop at 65°C water bath, react for 6h, then transfer to muffle furnace for high-temperature calcination, the calcination temperature is 1000°C, take it out for grinding after calcination, Pass through a 800-mesh sieve to get the infrared absorbing material.

[0034] A coating that can be used for infrared stealth, including infrared absorbing material, water-based acrylic resin, water-based polyurethane resin, nano hollow ceramic microspheres, dispersant 3218, NP-10, and hydroxypropyl methylcellulose;

[0035] The preparation method comprises the fol...

Embodiment 2

[0040] A method for preparing an infrared absorbing material, specifically: adding 16.82g of samarium nitrate and 2.25g of glycine into a container, then adding 600ml of distilled water and 2g of YF-02, ultrasonically dispersing for 40min, and then adding nitric acid with a mass concentration of 35% 20ml of yttrium aqueous solution, continue ultrasonic dispersion for 50min, add 15ml of 32.5% urea aqueous solution drop by drop at 70°C water bath, react for 5h, then transfer to muffle furnace for high-temperature calcination, calcination temperature is 1050°C, after calcination, take it out for grinding , through a 800-mesh sieve, the infrared absorbing material can be obtained.

[0041] A coating that can be used for infrared stealth, including infrared absorbing material, water-based acrylic resin, water-based polyurethane resin, nano hollow ceramic microspheres, dispersant 3218, NP-10, and hydroxypropyl methylcellulose;

[0042] The preparation method comprises the following ...

Embodiment 3

[0047] A method for preparing an infrared absorbing material, specifically: adding 16.82g of samarium nitrate and 2.25g of glycine into a container, then adding 400ml of distilled water and 2g of P-105, ultrasonically dispersing for 60min, and then adding nitric acid with a mass concentration of 40% 20ml of yttrium aqueous solution, continue ultrasonic dispersion for 60min, keep warm in a water bath at 60°C, add 15ml of concentrated ammonia water drop by drop, react for 8h, then transfer to a muffle furnace for high-temperature calcination, the calcination temperature is 1030°C, after the calcination, take it out and grind it, after 800 Mesh sieve, the infrared absorbing material can be obtained.

[0048] A coating that can be used for infrared stealth, including infrared absorbing material, water-based acrylic resin, water-based polyurethane resin, nano hollow ceramic microspheres, dispersant 3218, NP-10, and hydroxypropyl methylcellulose;

[0049] The preparation method comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com