Fumagillin extraction and purification method

A fumagillin and purification method technology, applied in the direction of organic chemistry, can solve the problems of complex operation steps, many impurities, high cost, etc., and achieve the effect of simple process operation, high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

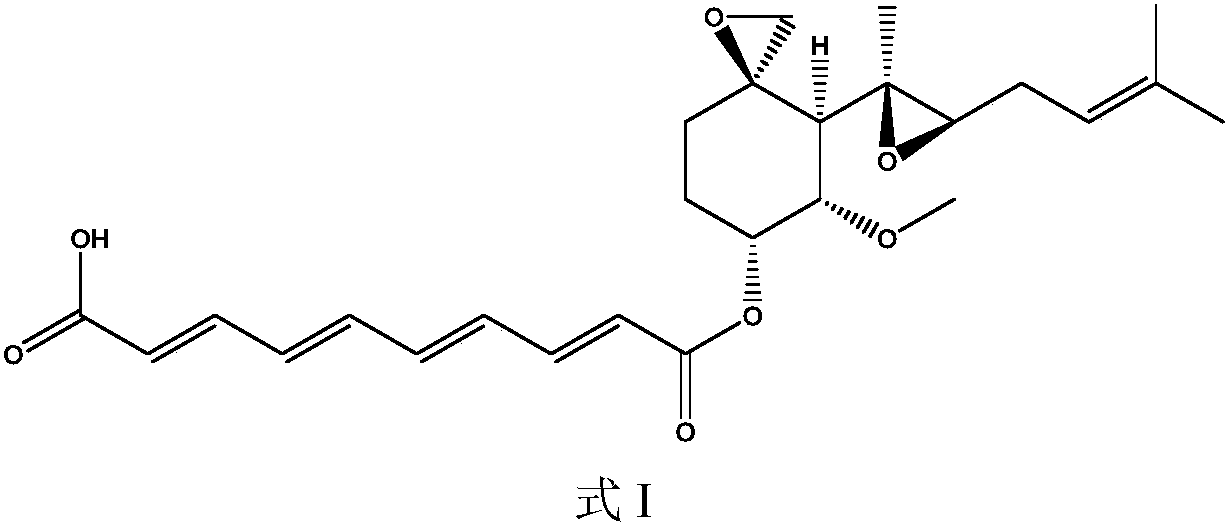

Image

Examples

Embodiment 1

[0042] The preparation of embodiment 1 fumagillin fermented liquid

[0043] The strain used in the fermentation culture in the examples of the present invention is a new fumagillin-producing strain, which is Penicillium sp. HS-NF-684Z, and its preservation number is CGMCC No. 14144.

[0044] The microbial strain of Penicillium HS-NF-684Z was preserved on July 24, 2017 in the General Microbiology Center of the China Committee for the Collection of Microbial Strains (Address: No. 3, Yard 1, Beichen West Road, Chaoyang District, Beijing, Microbiological Research, Chinese Academy of Sciences Institute), the preservation number is CGMCC No.14144, the classification name is Penicillium sp., and it is registered in the register to prove its survival.

[0045] The fumagillin fermented liquid culture process of the present invention is as follows:

[0046] (1) Preparation and cultivation of slant colonies

[0047] Potato glucose agar medium (g / L) was used as the slant medium: potato ...

Embodiment 2

[0055] Example 2 Fumagillin extraction and purification (carried out under dark)

[0056] Step a): get 30L of fumagillin fermented liquid (obtained according to the method described in Example 1), the total titer of fumagillin in the cell and extracellular is 1010mg / L (extracellular fumagillin effect valence is 216mg / L), add 45L MTBE (methyl tert-butyl ether), stir for 1h, let stand for 8h, separate liquid, collect MTBE extract phase 42L, take MTBE extract phase and analyze by HPLC, fumagillin concentration is 584.5 mg / L, the extraction yield was 81.0%;

[0057] Step b): Concentrate the MTBE extract phase obtained in step a) to 1.1 L at a concentration temperature of 30°C, then lower the temperature to 0°C, stir for 8 hours, and filter to obtain 50.0 g of fumagillin wet solid;

[0058] Step c): Dissolve the fumagillin wet solid obtained in step b) with 200ml of a mixed solvent of dichloromethane and methanol (the volume ratio of dichloromethane to methanol is 1:1), and filter...

Embodiment 3

[0060] Example 3 Fumagillin extraction and purification (carried out under dark)

[0061] Step a): get 30L of fumagillin fermented liquid (obtained according to the method described in Example 1), the total titer of fumagillin in the cell and extracellular is 1032mg / L (extracellular fumagillin effect valence is 180mg / L), add 90L ETBE (ethyl tert-butyl ether), stir for 5h, let stand for 10h, separate liquid, collect ETBE extract phase 84L, get ETBE extract phase and analyze by HPLC, fumagillin concentration is 310.2 mg / L, the extraction yield was 84.2%;

[0062] Step b): Concentrate the ETBE extract phase obtained in step a) to 2.8L, the concentration temperature is 30°C, then lower the temperature to 15°C, stir for 12h, and filter to obtain 52.6g of fumagillin wet solid;

[0063] Step c): Dissolve the fumagillin wet solid obtained in step b) with 420ml of a mixed solvent of dichloromethane and methanol (the volume ratio of dichloromethane to methanol is 5:1), and filter to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com