Preparation method for hydrophobic self-cleaning anti-reflection film with high hardness and super wear-resistance

A technology of super wear-resistant and anti-reflection film, applied in the direction of coating, etc., can solve the problem of light transmittance decline, and achieve the effects of low cost, simple preparation process, high hardness and refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Preparation of AlO(OH) sol: use absolute ethanol as solvent and aluminum isopropoxide (purity ≥ 98%) as precursor, heat absolute ethanol to 80°C, stir at 600 rpm, Add aluminum isopropoxide about 1 / 400 of the number of solvent moles in one second, reflux and stir for 30 minutes, then heat up to 90°C, add concentrated nitric acid (HNO 3 , 36%), refluxed for 6 hours, cooled, then sealed and stored, and aged for 96 hours at room temperature to obtain a transparent and stable aluminum sol. The molar ratios of added absolute ethanol, aluminum isopropoxide, and nitric acid are 100:1:0.25, respectively.

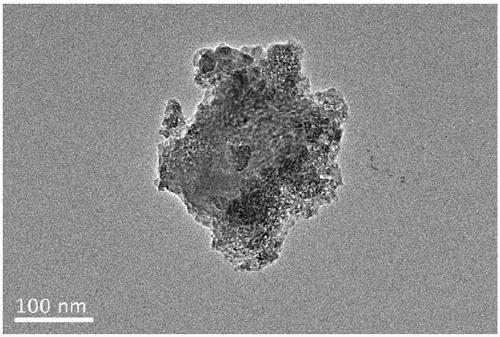

[0030] Al-wisker / SiO2 2 Preparation of sol: take the prepared aluminum sol, add methyltriethoxysilane (MTES, 96%) and oxalic acid solution (0.01mol / L) drop by drop under stirring at 30°C, stir for 1h, and age at 30°C 5 days. The volume ratio of AlO(OH) sol, MTES and oxalic acid added is 5:1:0.5.

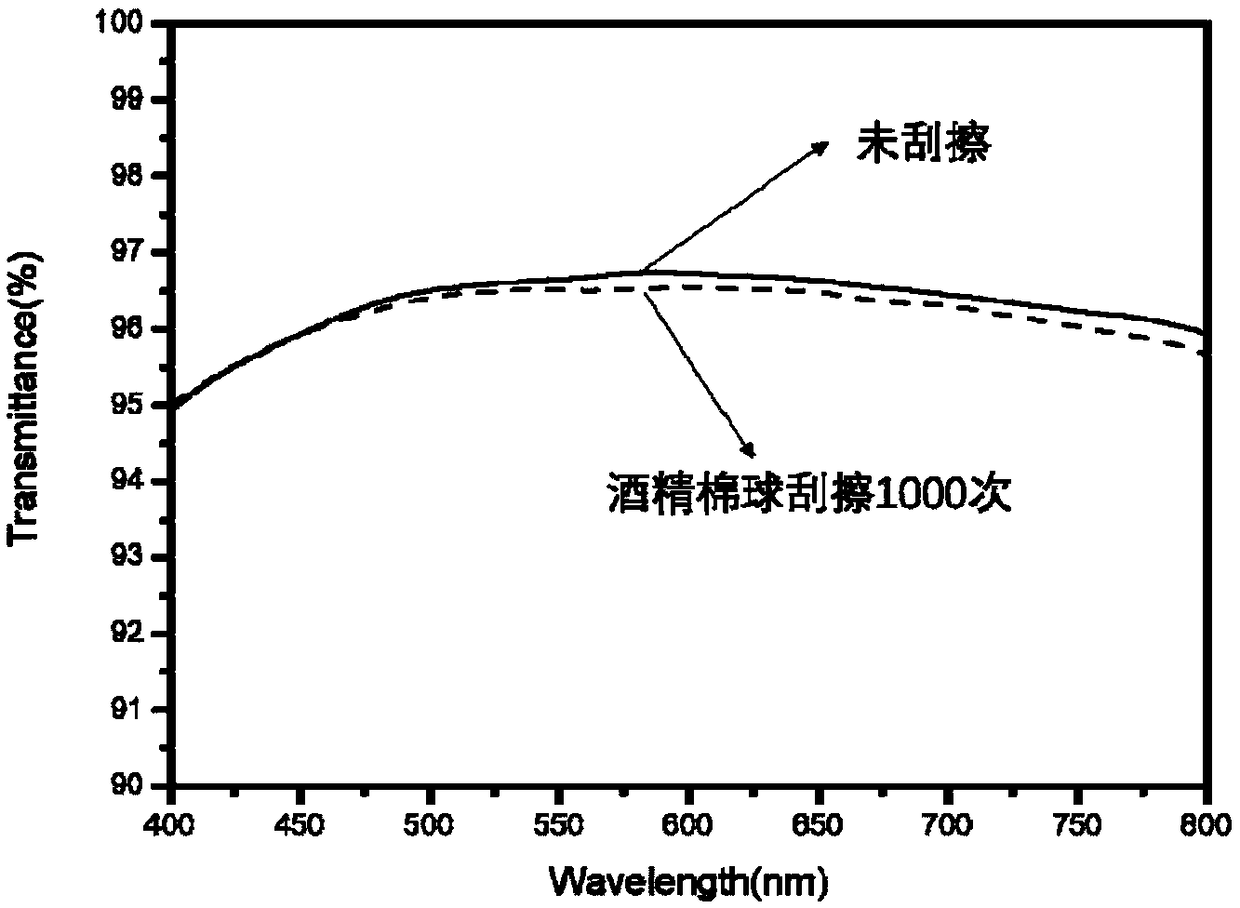

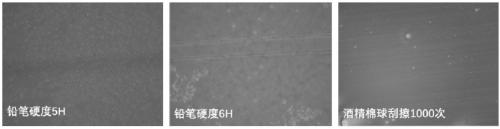

[0031] Al-wisker / SiO2 2 Preparation of the anti-reflection film: take high b...

Embodiment 2

[0033] Preparation of AlO(OH) sol: use absolute ethanol as solvent and aluminum isopropoxide (purity ≥ 98%) as precursor, heat absolute ethanol to 80°C, stir at 600 rpm, Add about 1 / 400 of the number of solvent moles in one second and slowly add aluminum isopropoxide, reflux and stir for 30 minutes, then raise the temperature to 90°C, add concentrated nitric acid (HNO 3 , 36%), refluxed for 6 hours, cooled, then sealed and stored, and aged for 96 hours at room temperature to obtain a transparent and stable aluminum sol. The molar ratios of added absolute ethanol, aluminum isopropoxide, and nitric acid are 100:1:0.25, respectively.

[0034] Al-wisker / SiO2 2 Preparation of sol: take the prepared aluminum sol, add methyltriethoxysilane (MTES, 96%) and oxalic acid solution (0.01mol / L) drop by drop under stirring at 30°C, stir for 1h, and age at 30°C 5 days. The volume ratio of AlO(OH) sol, MTES and oxalic acid added is 10:1:0.5.

[0035] Al-wisker / SiO2 2 Preparation of the an...

Embodiment 3

[0037] Preparation of AlO(OH) sol: use absolute ethanol as solvent and aluminum isopropoxide (purity ≥ 98%) as precursor, heat absolute ethanol to 80°C, stir at 600 rpm, Add aluminum isopropoxide about 1 / 400 of the number of solvent moles in one second, reflux and stir for 30 minutes, then heat up to 90°C, add concentrated nitric acid (HNO 3 , 36%), refluxed for 6 hours, cooled and sealed for storage, and aged for 96 hours at room temperature to obtain a transparent and stable aluminum sol. The molar ratios of added absolute ethanol, aluminum isopropoxide, and nitric acid are 100:1:0.25, respectively.

[0038] Al-wisker / SiO2 2 Preparation of sol: take the prepared aluminum sol, add methyltriethoxysilane (MTES, 96%) and oxalic acid solution (0.01mol / L) drop by drop under stirring at 30°C, stir for 1h, and age at 30°C 5 days. The volume ratio of AlO(OH) sol, MTES and oxalic acid added is 15:1:0.5.

[0039] Al-wisker / SiO2 2 Preparation of the anti-reflection film: take high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com