Inclined vertical type retractable board machine for PCB production line

A PCB board and production line technology, which is applied in the field of inclined vertical retractable board machine, can solve the problems of traces on the surface of the PCB board, affecting the appearance of the PCB board, affecting the working efficiency of the production line, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

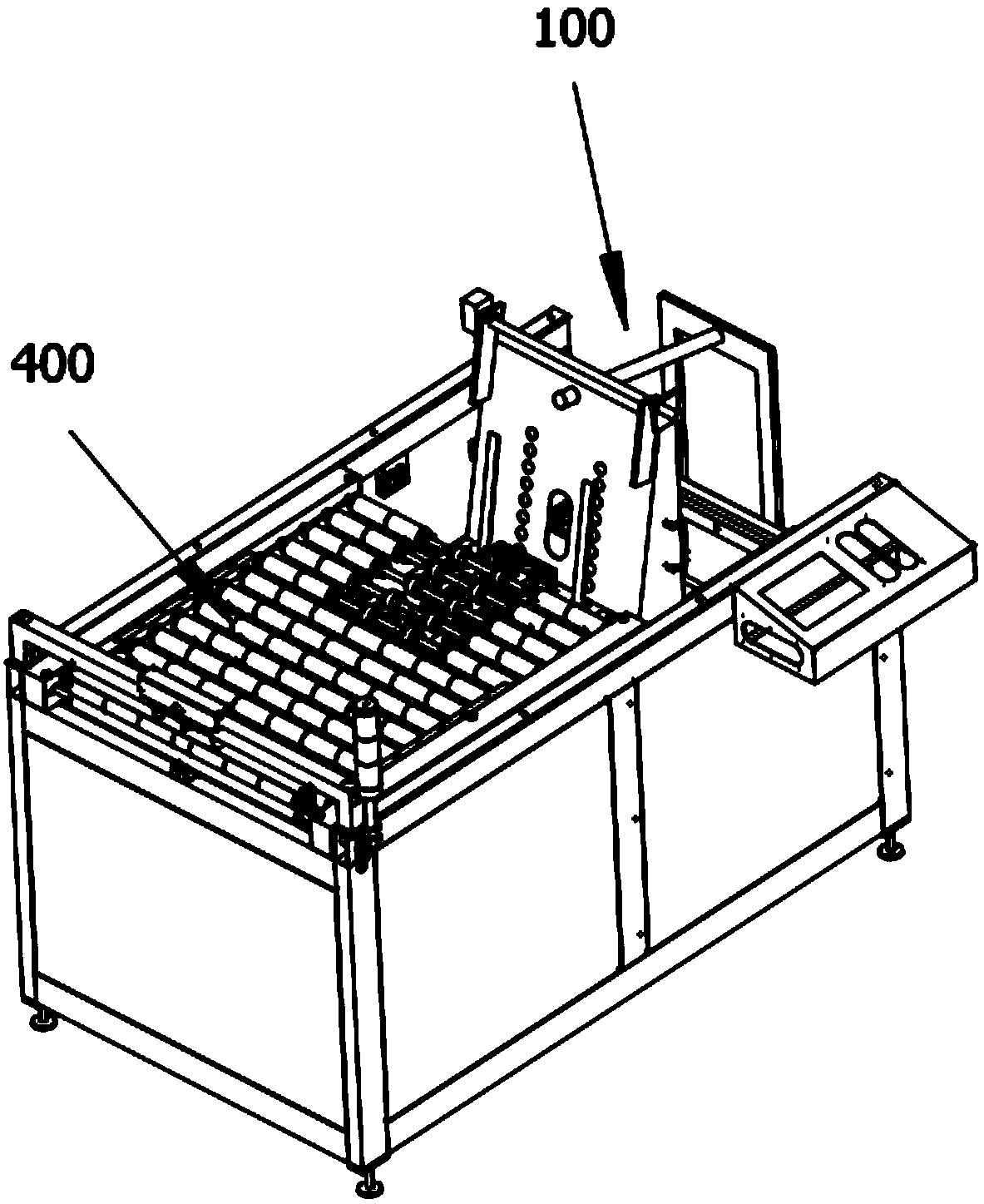

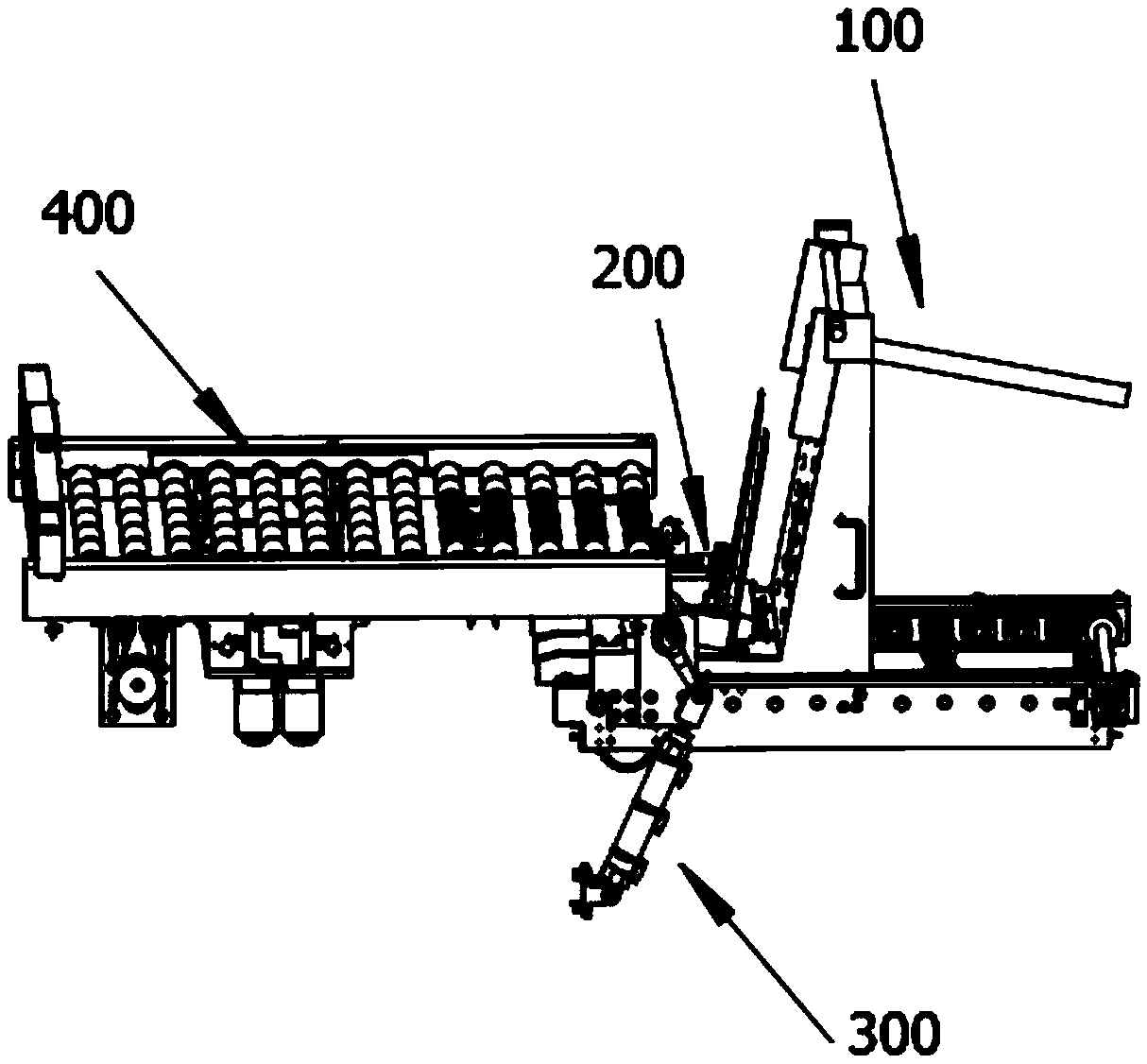

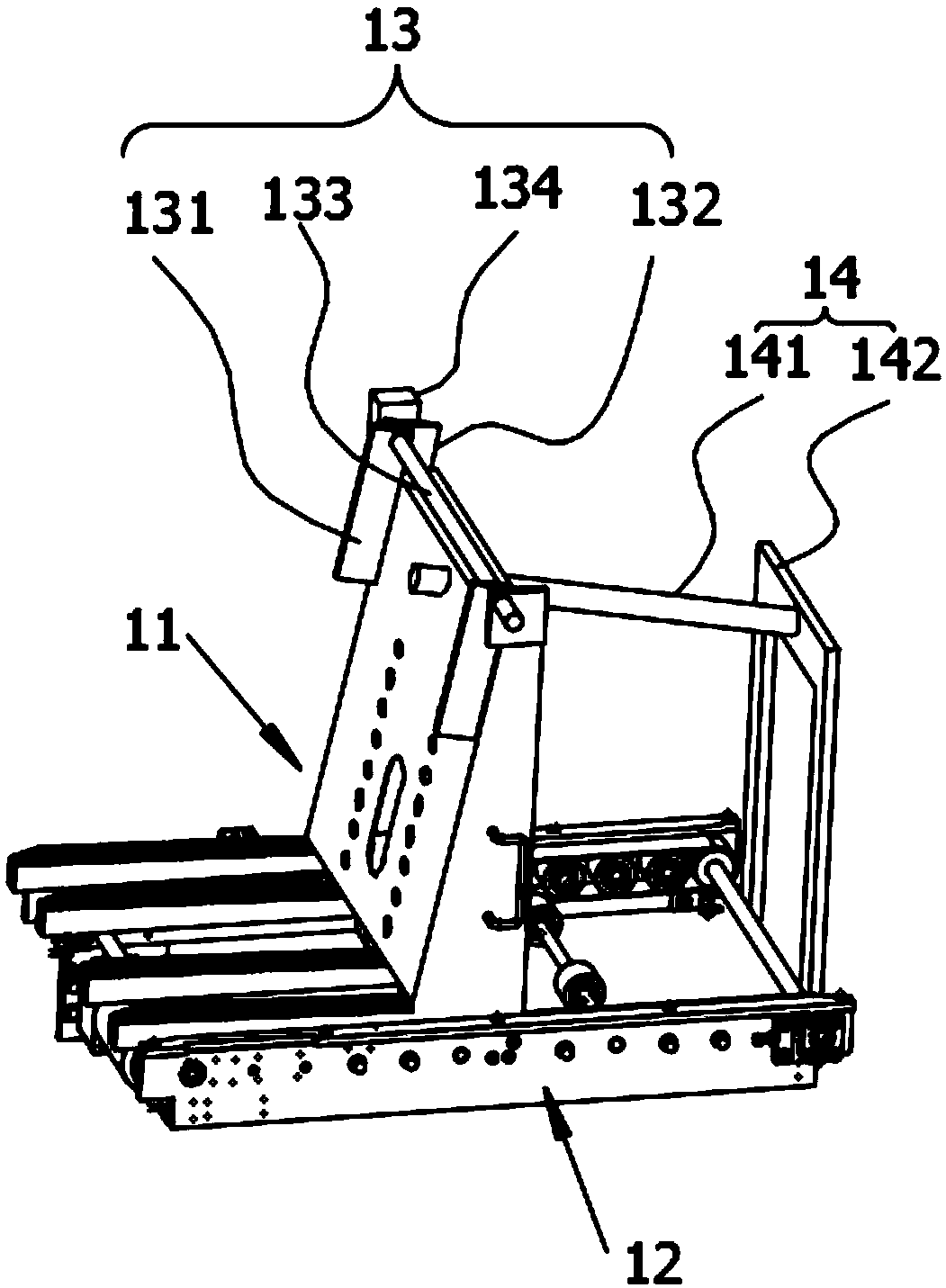

[0051] Embodiment: a kind of PCB board production line is used oblique vertical board machine, as Figure 1-Figure 11 As shown, including the frame, according to the material conveying direction, it includes a plate frame transmission mechanism 100 fixed on the frame, a suction plate mechanism 200, a plate turning mechanism 300 and a horizontal conveying mechanism 400;

[0052] The plate frame transmission mechanism includes a plate frame 11 and a transmission structure 12 that drives the plate frame to move back and forth. The transmission structure includes a transmission bracket 121 fixed on the left and right sides of the frame, at least two transmission rollers 122 that are rollingly connected with the transmission bracket, A transmission belt 123 wound between two transmission rollers and driven by the transmission rollers and a first motor 124 that drives at least one transmission roller to rotate, one end of the transmission roller is fixedly connected to the output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com