Centrifugal device for round ball sorting

A centrifugal device and sorting technology, which is applied in the direction of solid separation, classification, chemical instruments and methods, etc., can solve the problem that the sorting accuracy cannot meet the production needs, achieve uniform force, ensure stability, and reduce collision friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

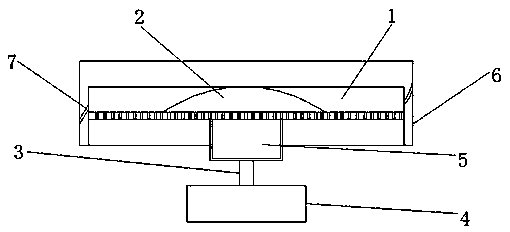

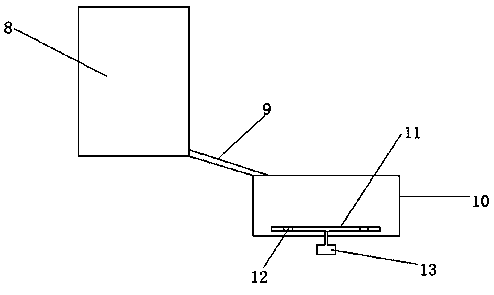

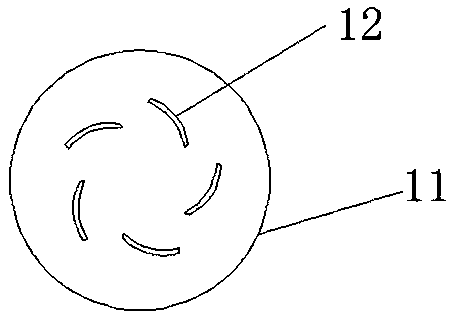

[0019] figure 1 It shows a centrifugal device for sorting round balls, including a sorting disc 1, a sorting body 2, a rotating shaft 3 and a power unit 4. The circular opening of the sorting disc 1 is upward, and the disc 1 is downward. The bottom surface is sunken downward to form a hollow separation cavity, and the sorting body is installed in the separation cavity. The sorting body 2 is a vertebral structure, the busbar of the sorting body 2 is a single-leaf hyperbola, and the rotating shaft 3 is fixed on the lower bottom of the sorting body. The central axis of the rotating shaft 3 is collinear with the central axis of the sorting disc 1, the output end of the power device is connected to the rotating shaft, and the rotating shaft is connected to the sorting disc through a reduction gear.

[0020] Further, the hyperbolic equation is:

[0021] X² / 4.17²-Y² / 9.64²=1;

[0022] Among them, x and y are the point coordinates on the hyperbola, the thickness of the hyperboloid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com