Workpiece conveying and screening equipment

A technology for screening equipment and workpieces, which is applied in the field of workpiece conveying and screening equipment, can solve problems such as affecting work efficiency, slow screening speed of roller shafts, affecting screening efficiency, etc., and achieves a good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

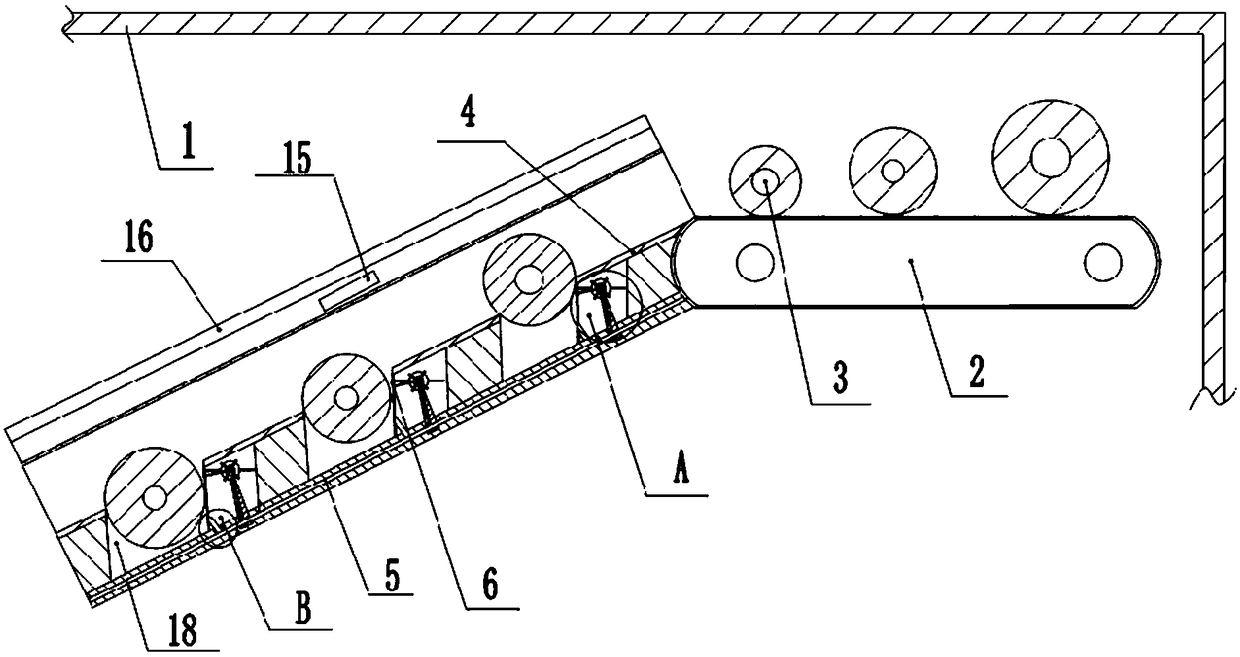

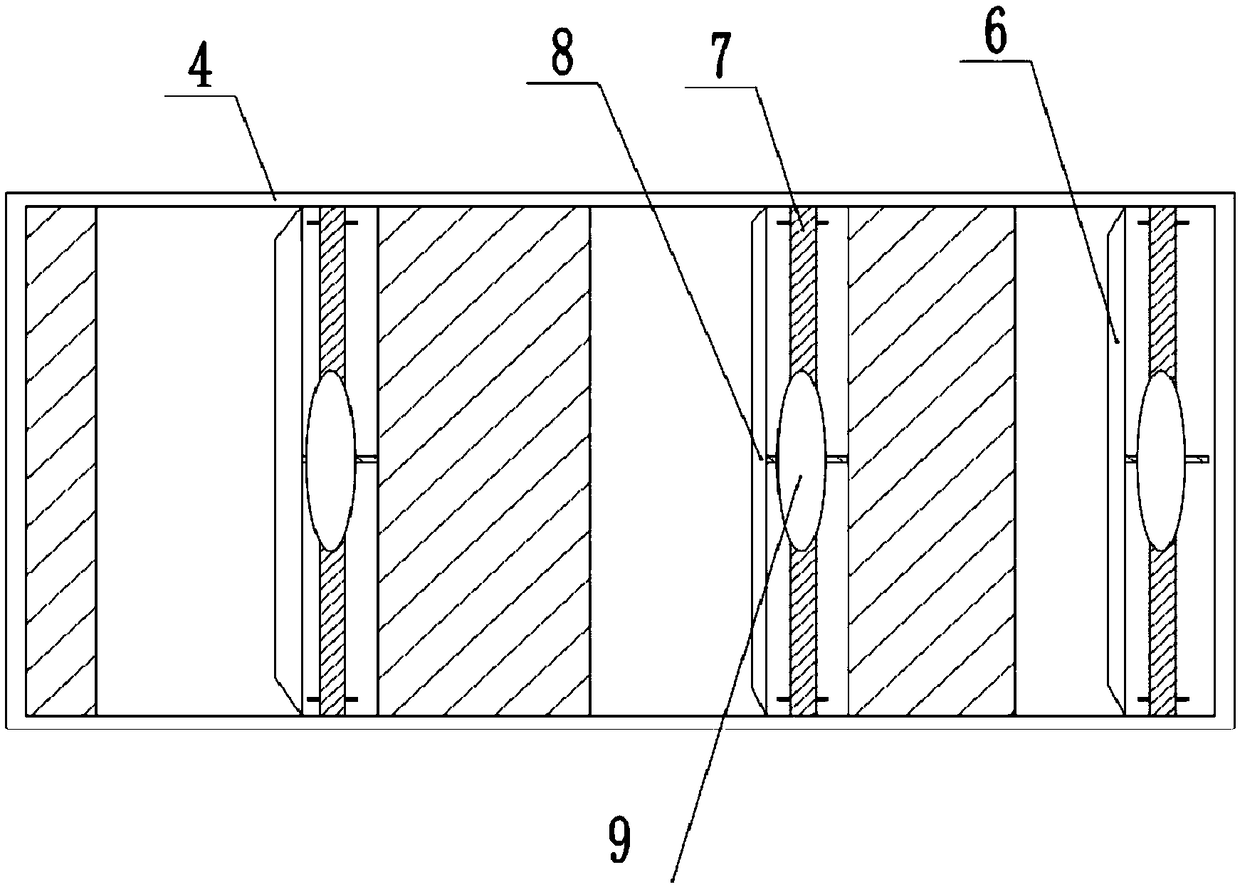

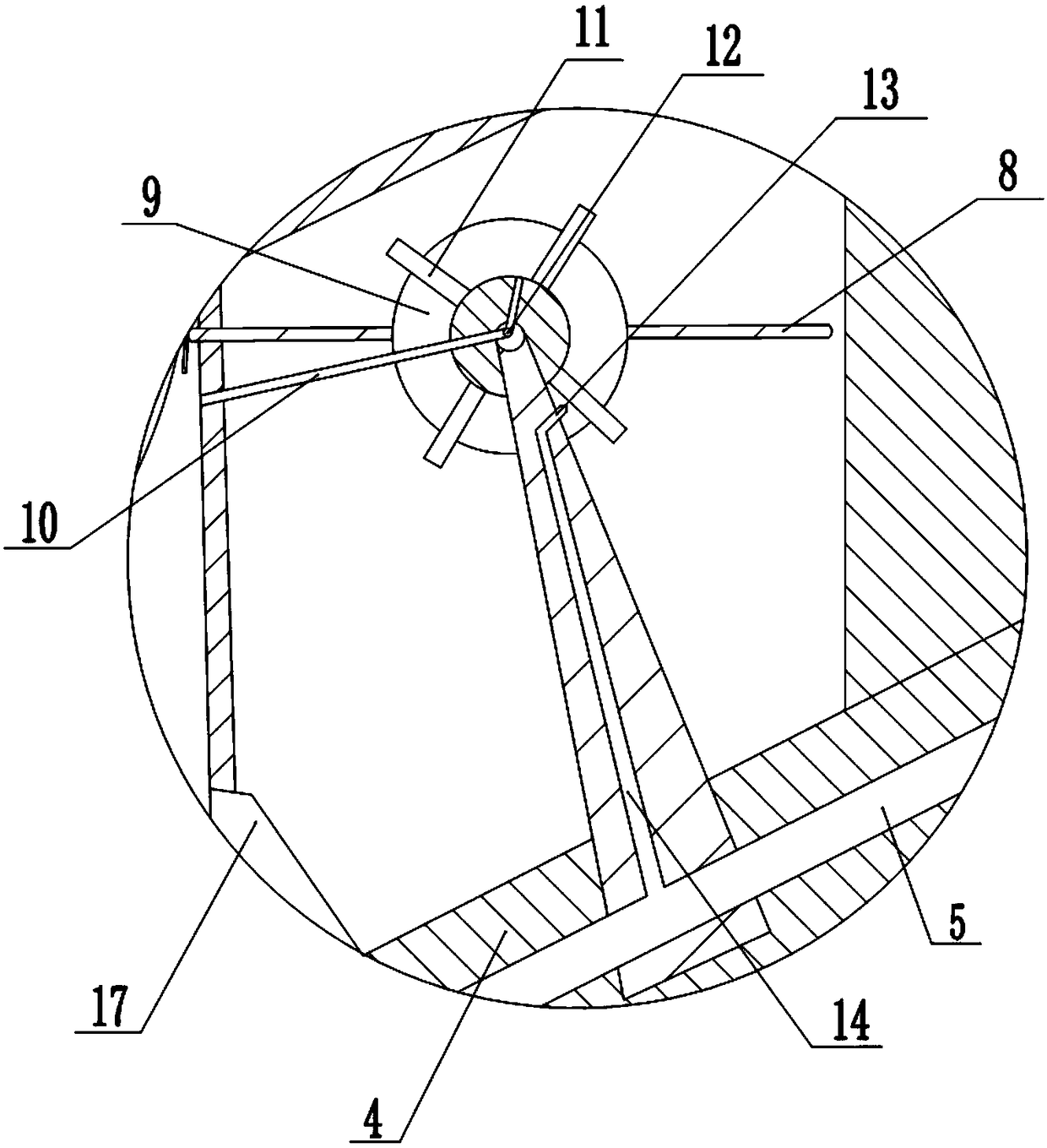

[0022] The reference signs in the drawings of the description include: frame 1, conveyor belt 2, roller shaft 3, screening plate 4, air channel 5, movable plate 6, rotating shaft 7, pole 8, elastic air bag 9, hose 10, fan Leaf 11, first passage 12, air nozzle 13, second passage 14, negative pressure fan 15, negative pressure chamber 16, air pipe 17, screening tank 18.

[0023] Such as figure 1 and figure 2 As shown, the workpiece conveying and screening equipment includes a frame 1, a conveyor belt 2 installed on the frame 1, and a screening plate 4 arranged obliquely at the left end of the conveyor belt 2; the screening plate 4 is fixedly connected with the frame 1, and the screening plate 4 is provided with There are three screening slots 18, and the opening sizes of the three screening slots 18 increase sequentially from top to bottom. A movable plate 6 is hinged at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com