Drink machine locked through press fit of lever

A beverage machine and lever technology, applied in the field of beverage extraction and brewing, can solve the problems of incompatibility with bulging capsules, unsmooth pressing, poor sealing, etc., achieving small pressing force, smooth pressing process, and solving problems that are easy to leak water. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

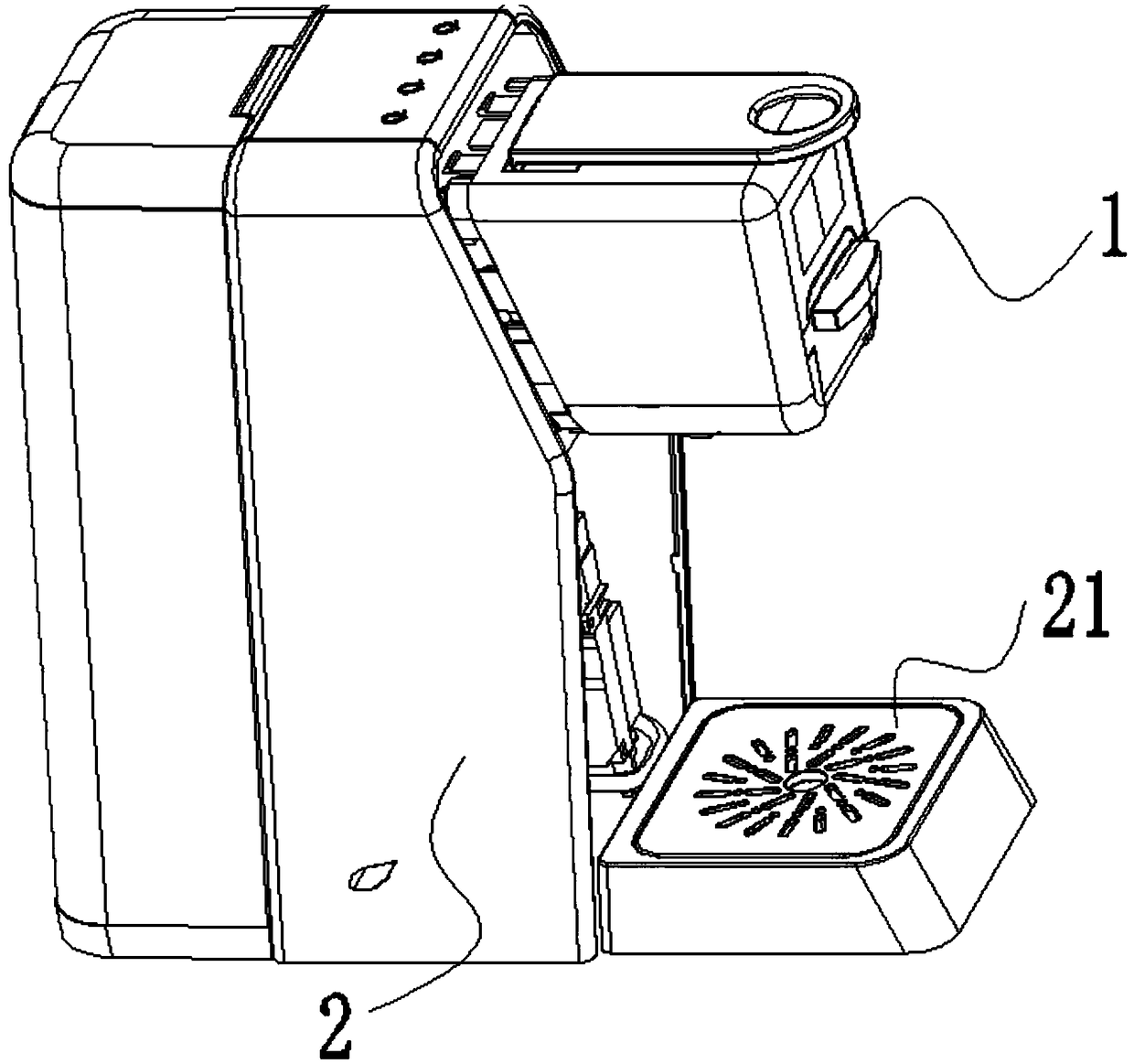

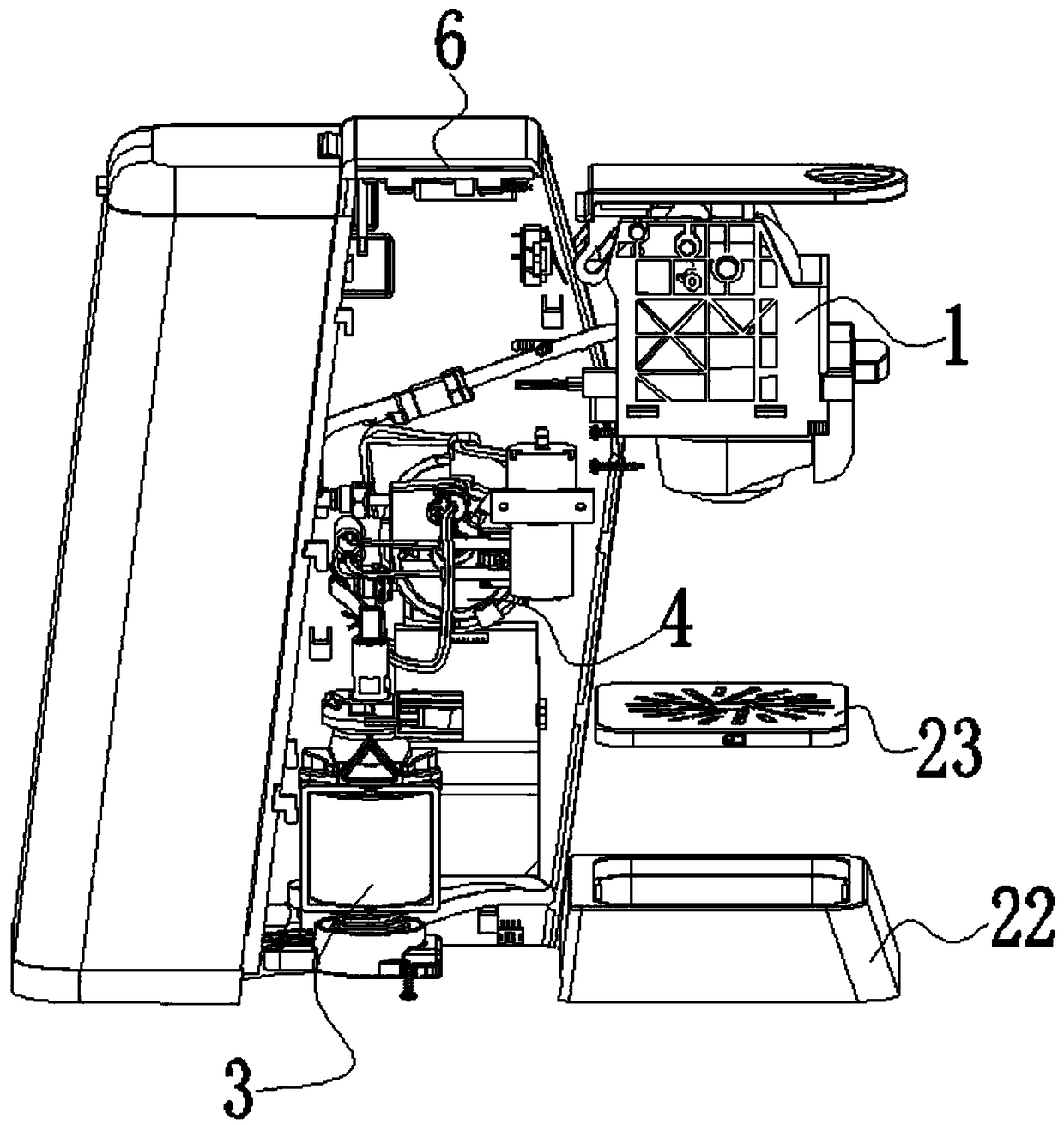

[0055] refer to Figure 1 to Figure 8 , a beverage machine that uses lever pressing and locking, including: a housing 2, a water tank 3 disposed in the housing 2 for storing water, an electromagnetic pump 4 communicated with the water tank 3 in the housing 2, and a water tank 3 disposed in the housing 2 A heater 5 communicating with the electromagnetic pump 4, an extraction assembly 1 arranged in the casing 2 communicating with the heater 5, and a control module 6 arranged on the casing 2 and connected to the water tank 3, the electromagnetic pump 4, and the heater 5 respectively;

[0056] Wherein, a water valve seat 7 for controlling water outlet is provided between the electromagnetic pump 4 and the water tank 3; a flow meter 8 for calculating the water volume is provided at the adjacent position of the water valve seat 7; Pressure relief valve 9 for adjusting water pressure;

[0057] Wherein, the extraction assembly 1 includes: a bracket 15 for fixing, a capsule compartmen...

Embodiment 2

[0063] refer to Figure 4 ~ Figure 5 The difference from the above embodiments is that the press-fit sealing member 12 includes: an end cap 121 arranged at the lower end of the press-fit part 113 and a sealing ring 122 arranged between the end cap 121 and the capsule compartment 13, and the water inlet member 14 penetrates through End cap 121 and sealing ring 122 are set;

[0064] Wherein, a slide block 123 is installed at the corresponding position of the end cover 121 and the slide rail 151, and the limit end cover 121 can only move in the vertical direction, and the end cover 121 is provided with a limit rod 124 near the pressing part 113 to limit the pressing part. 113 and the relative position between the end cap 121.

[0065] Further, the water inlet member 14 includes a water inlet needle 141 for piercing and water inlet and a water guide pipe 142 connected to the water inlet needle 141, the water inlet needle 141 is fixed to the end cap 121 of the press-fit sealing me...

Embodiment 3

[0067] refer to Figure 5 , the difference from the above-mentioned embodiments is that a touch switch 1102 is also provided on the handle 110, the touch switch is electrically connected to the control module, and the power supply is controlled through the touch switch 1102. When the handle 110 is lifted to place the capsule, the touch switch 1102 will work to turn on the power-off protection. After the capsule is placed, the power will be turned on. Dual circuit protection ensures personal safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com