A galloping starting method based on power-frequency-to-variable-frequency switching of a nine-phase motor

A technology of flying car start and power frequency, applied in the field of frequency conversion control, can solve the problems of narrow application area and long waiting time of nine-phase motor, and achieve the effect of reducing waiting time and wide application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

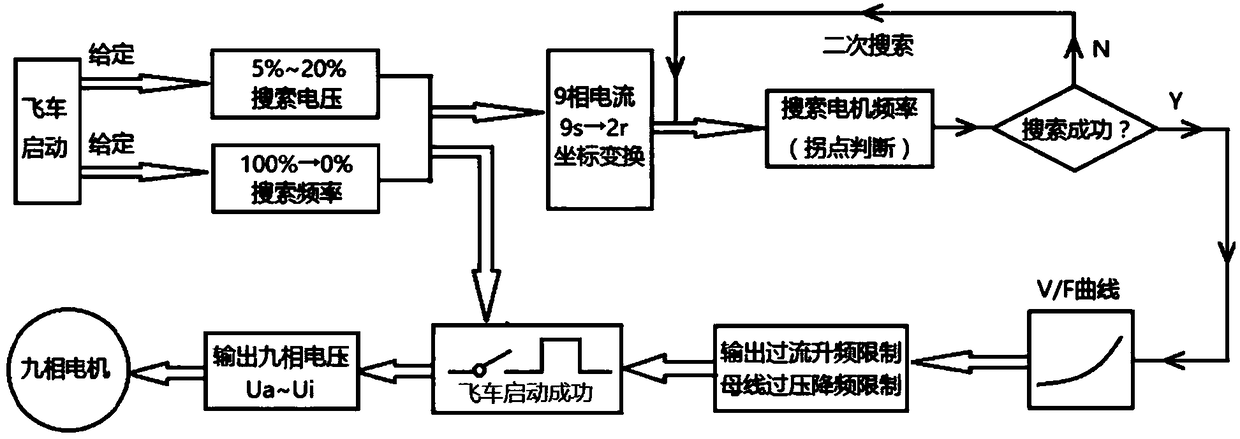

[0022] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

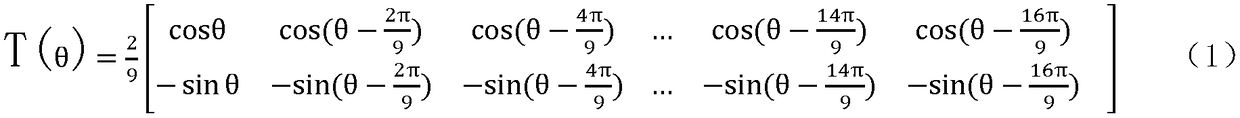

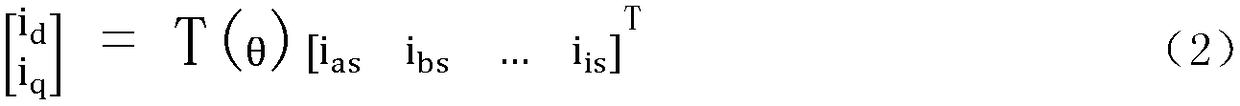

[0023] Such as figure 1 As shown, a flying start method based on a nine-phase motor power frequency cut frequency conversion, including the following steps:

[0024] Step 1. After the motor is switched from power frequency to variable frequency, the inverter first sets an initial output voltage for the rotating motor, and at the same time the given frequency of the inverter gradually ramps down from the rated frequency to 0Hz;

[0025] The initial output voltage is given according to the "full-scale" voltage, which is 5% to 20% of the rated voltage Ue, and is adjusted within 5% to 20% of Ue according to the resistance of the motor stator to ensure that the current is within the rated range. While limiting the output current, it builds negative feedback on the voltage output to automatically suppress overcurrent.

[0026] Step 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com