Liquid crystal display panel and preparation method thereof

A technology of liquid crystal display panels and array substrates, applied in nonlinear optics, instruments, optics, etc., can solve the problems of being unable to act as a barrier, unable to make a raised barrier, and unable to have a barrier, so as to avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

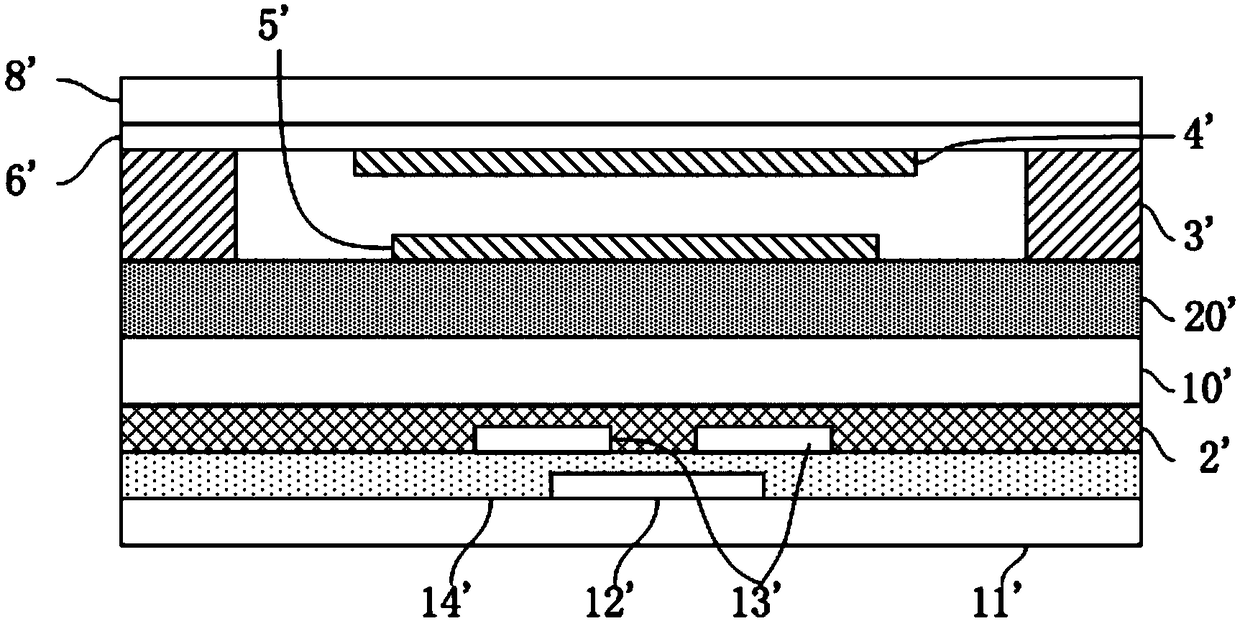

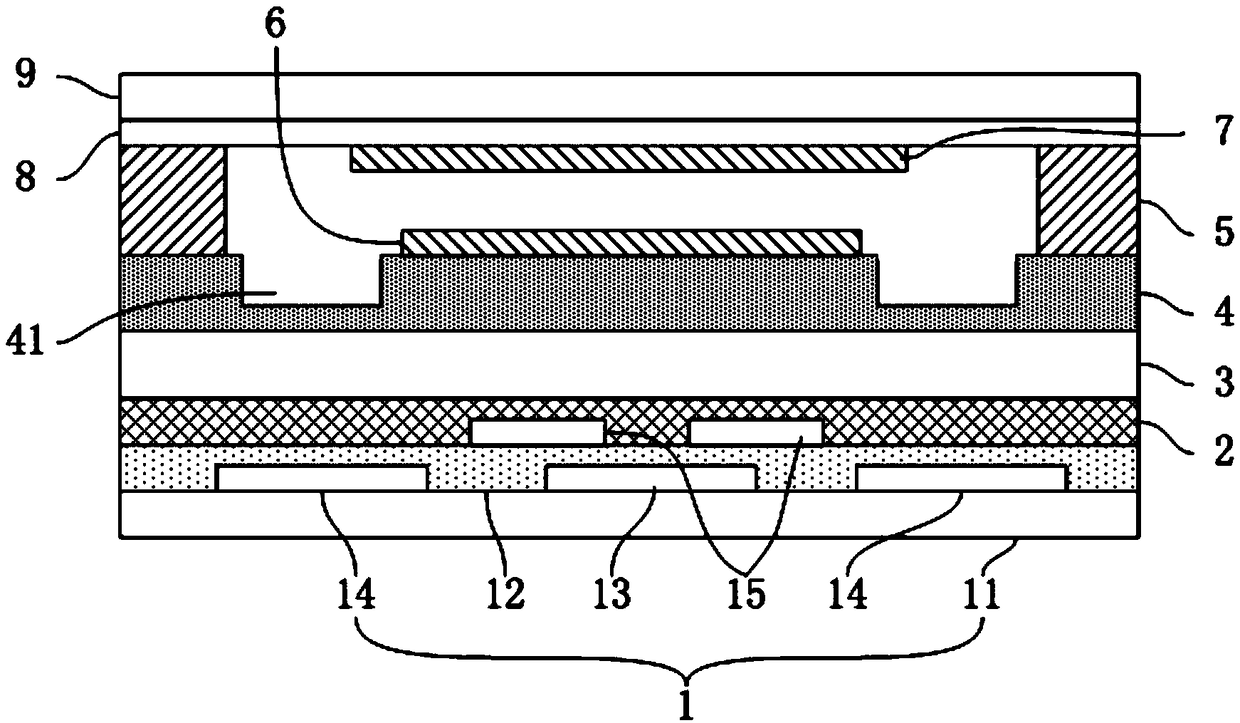

[0033] The invention provides a liquid crystal display panel, such as image 3 The liquid crystal display panel shown includes: an array substrate 1, a passivation layer 2, a planarization layer 3, a BPS (Black photo spacer, black photoresist pad material) material layer 4 sequentially stacked on the array substrate 1, and a first alignment layer 6 , the projection of the first alignment layer 6 on the BPS material layer 4 does not exceed the area of the BPS material layer 4 . The material of the alignment layer is polyimide material.

[0034] Such as Figure 4 As shown, a plurality of grooves 41 are provided on the BPS material layer 4, and the plurality of grooves 41 are distributed along the inner side of the edge of the BPS material layer 4, and a frame glue 5 is also formed on the BPS material layer 4; wherein, The sealant 5 and the first alignment layer 6 are respectively located on two sides of the plurality of grooves 41 .

[0035] Here, since the BPS material lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com