Industrial rail parallelism detection robot

A technology of parallelism and robotics, applied in the direction of instruments, measuring devices, optical devices, etc., can solve problems such as installation troubles, robot disassembly troubles, inconvenient maintenance and replacement parts, etc., to achieve simple installation work, clear test results, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

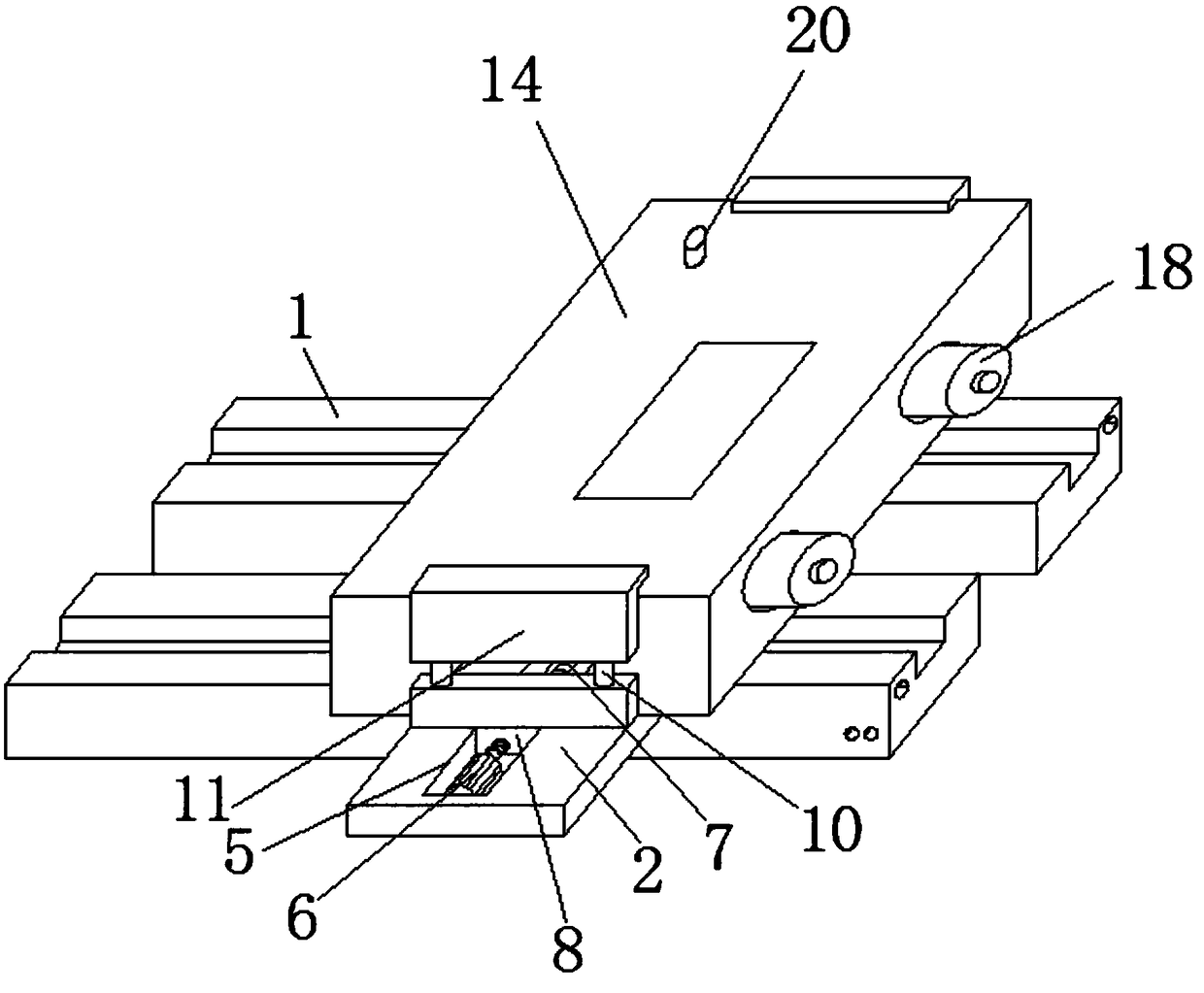

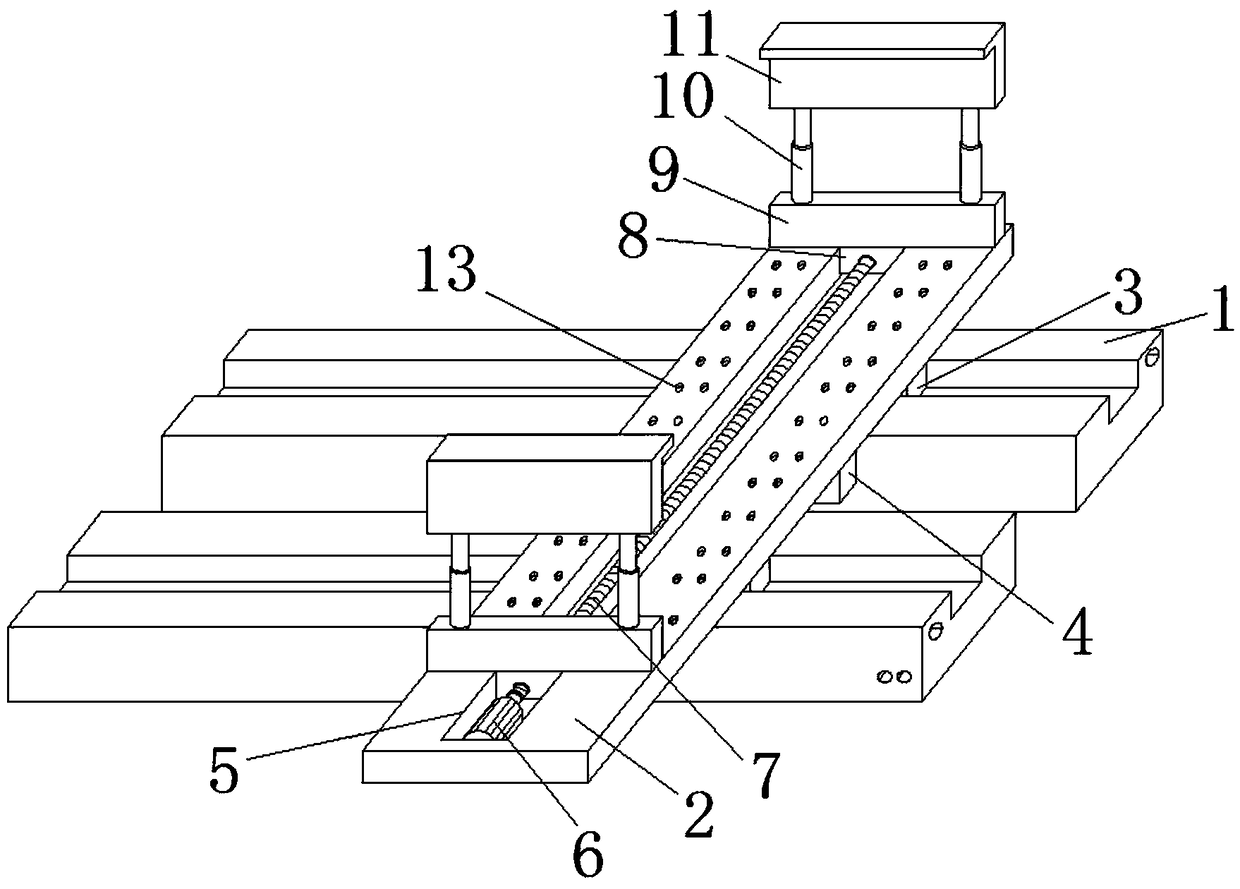

[0022] see Figure 1-4 , the present embodiment provides an industrial track parallelism detection robot, comprising two track bodies 1 and a positioning plate 2, the bottom of the positioning plate 2 is fixedly connected with a hinged seat 19, and the hinged seat 19 The bottom is hinged with a detection slider 3, the detection slider 3 is slidingly connected with the track body 1, the bottom of the positioning plate 2 is fixedly installed with a driving wheel assembly 4, the driving wheel assembly 4 is movably connected with the track body 1, and the top of the positioning plate 2 is opened There is a chute 5, the inner wall of the chute 5 is fixedly connected with a motor 6, the output shaft of the motor 6 is fixedly connected with a screw rod 7, the surface of the screw rod 7 is threadedly connected with a screw rod sliding sleeve 8, and the top of the screw rod sliding sleeve 8 is fixed Connected with a moving plate 9, the top of the moving plate 9 is fixedly connected wit...

Embodiment 2

[0025] see Figure 1-4 , on the basis of Example 1, a further improvement has been made: there is a gap between the bottom of the positioning plate 2 and the track body 1, and the positioning plate 2 is not in contact with the track body 1, which can effectively prevent the stains on the track body 1 from affecting the measurement results As a result, the drive wheel assembly 4 includes an asynchronous motor and a drive wheel, the asynchronous motor and the drive wheel are connected in rotation, and the power supply is controlled by the control assembly 17, so that the asynchronous motor drives the drive wheel to rotate, so that the robot can move by itself, and the positioning plate The top of 2 is provided with evenly distributed heat dissipation holes 13 to avoid excessive heat generation at the contact with the positioning plate 2 when the robot is working.

[0026] Wherein, the inner wall of the chute 5 is fixedly connected with a rotating seat 12, and the inner wall of t...

Embodiment 3

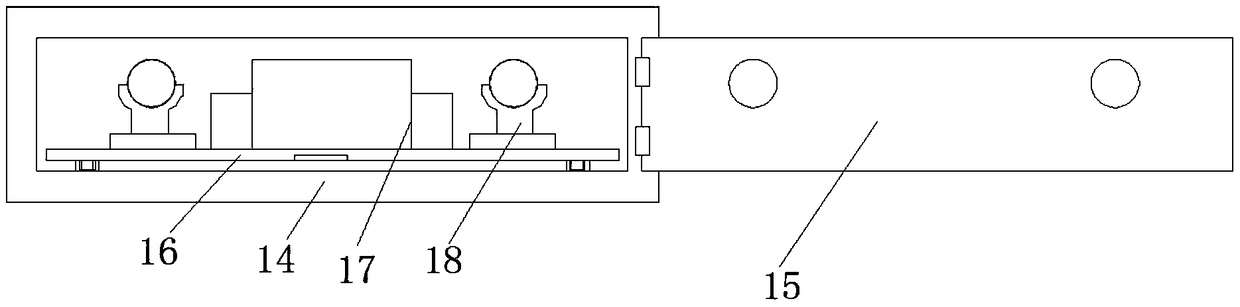

[0028] see figure 1 Or 3, a further improvement is made on the basis of Embodiment 1: the control assembly 17 includes a battery and a central controller, and when the parallelism is detected, the battery is used to supply power to the device, and the central controller plays a role in controlling the entire motion process , the top of the casing 14 is fixedly connected to the limit guide rail, the inner wall of the limit guide rail is slidably connected with a slider, the slider is fixedly connected to the mounting plate 16, and the sliding block slides inside the limit guide rail, so that the pulling of the mounting plate 16 can be made more efficient. Smooth, and can play a position-limiting effect on the mounting plate 16, preventing it from tilting or shifting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com