Gas distribution system of engine, and engine

A technology of engine and active gear, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of increased engine operating noise, changes in the matching relationship of components, and affecting the service life of components, etc., achieving a simple and compact structure, avoiding The effect of loose installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

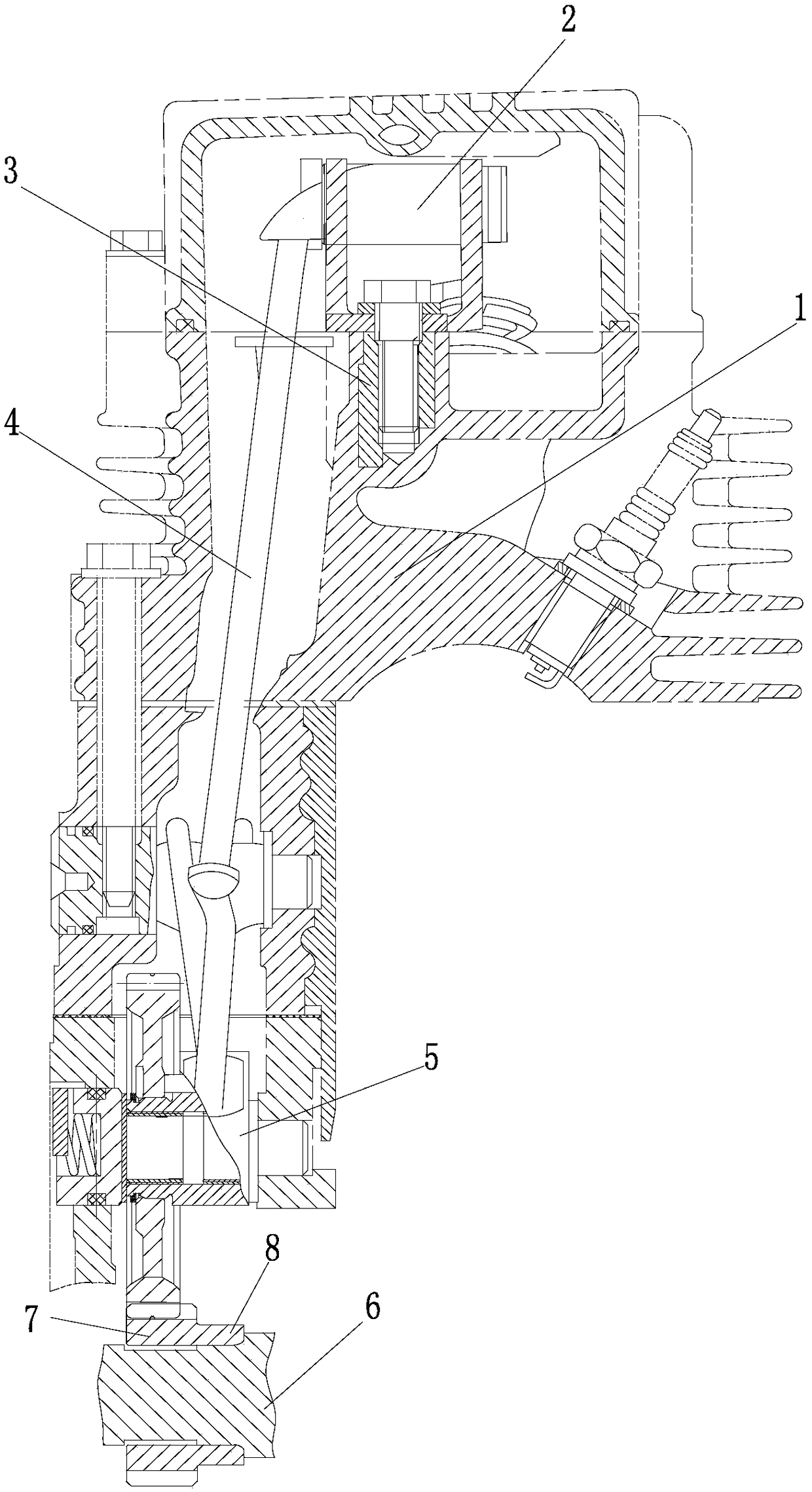

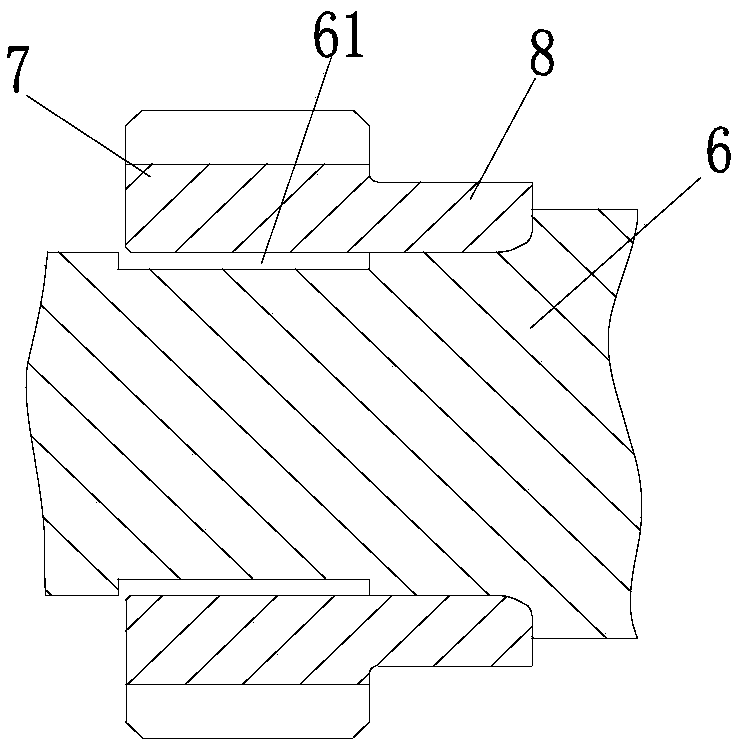

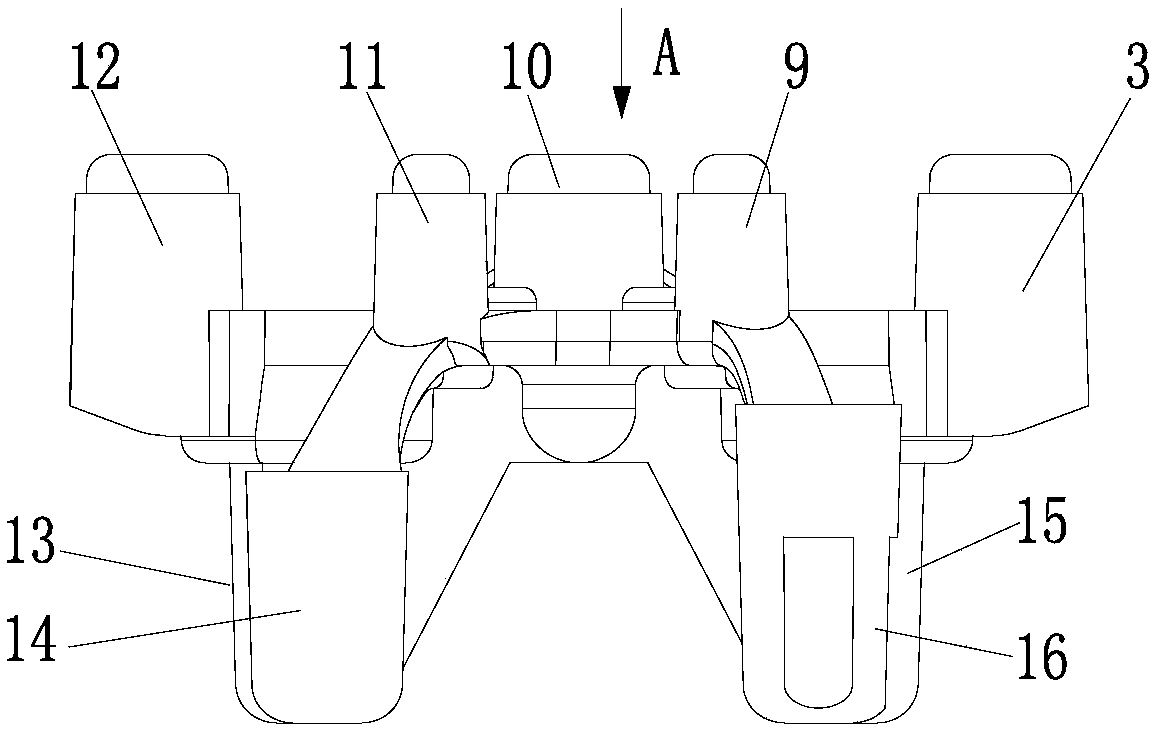

[0023] As shown in the figure: the engine gas distribution system of the present embodiment, the timing driving gear of the gas distribution system includes a timing driving gear body 7 and a shaft sleeve 8 formed by axially extending the timing driving gear body 7 (by the timing driving gear body 7) The side of the timing driving gear is integrally formed to extend out of the shaft sleeve, which can be understood as a shaft shoulder structure), and the timing driving gear body 7 forms a transmission through the shaft sleeve 8 that is sleeved on the crankshaft 6 through transmission, and the gap of the timing driving gear body is sleeved on Crankshaft 6: In the existing design, the timing gear is directly driven (interference) and press-fitted on the crankshaft. Due to the interference force and thermal deformation, the tooth profile of the timing driving gear will be deformed. Unfavorable consequences such as noise and other adverse consequences caused by poor operation will e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com