Model of underground gasification furnace and furnace building and gasification method

An underground gasification and furnace type technology, which is applied in coal gasification, underground mining, construction, etc., can solve the problems of long period of reaching production capacity, unstable gas composition and gas volume, and affecting the stability of gasification operation, so as to solve the problem of reaching production capacity Long cycle, solve the effect of long start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

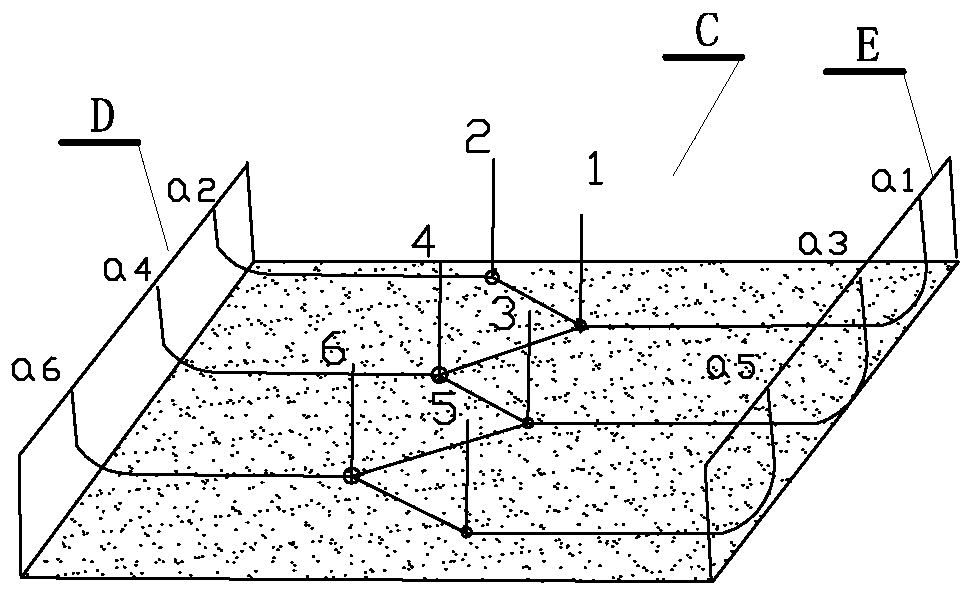

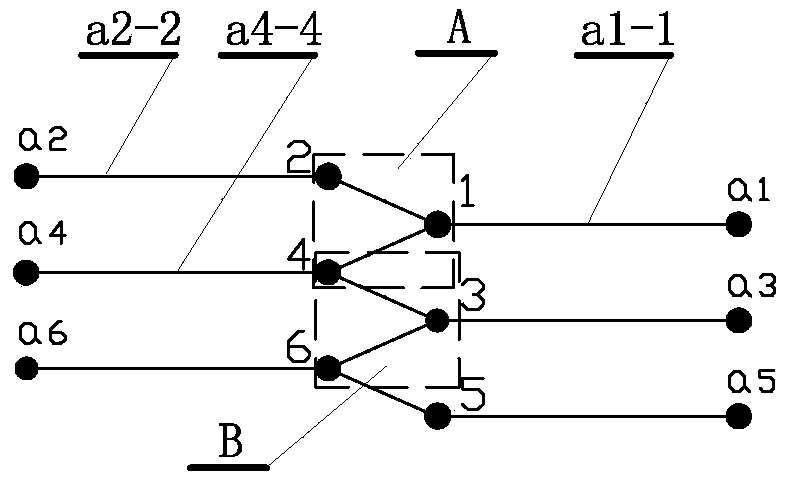

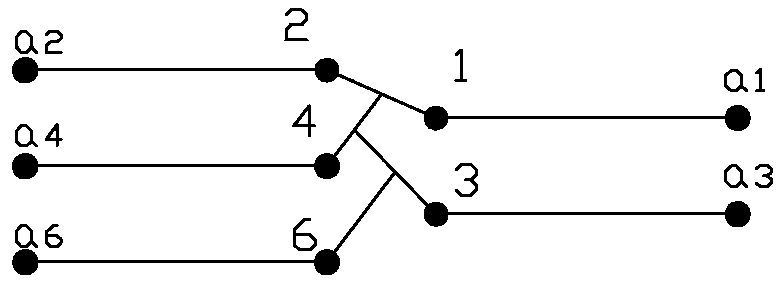

[0040] An underground gasifier furnace type, such as figure 1 and 2 As shown, the underground gasifier furnace type includes multiple gasification unit furnaces figure 2 Only A and B are shown, and there may be multiple gasification unit furnaces connected to each other. Multiple gasification unit furnaces are set in the rectangular mining area C, and the rectangular mining area C can be used in a large coal mining area according to According to actual needs, the gasification unit furnace includes three gas outlet wells 1, 2 and 4, and the three gas outlet wells extend downward to the coal seam in the mining area; the three gas outlet wells are arranged in a triangle, and two of them Gas outlet wells 2 and 4 are at the same distance from an edge D of the rectangular production area to form two gas outlet wells at the two corners of the triangle bottom, and the remaining gas outlet well 1 is a gas outlet well at the top corner of the triangle. Two air intake wells a2 and a4 ...

Embodiment 2

[0049] A method for building an underground gasification furnace is based on the method for building an underground gasification furnace in Example 1. Therefore, the content in Example 1 is also applicable to this embodiment. First, an underground gasification method must be determined. The furnace is built in a rectangular mining area, and the gasification unit furnaces are sequentially established in the rectangular mining area and gasification is sequentially connected to produce gas. This method adopts a backward ignition process for gas production, and the backward ignition process for gas production uses a known technical solution. , is the applicant’s patent application number 201810781695X "A Coal Seam Ignition Device for an Underground Gasifier and a Backward Repeated Ignition Gasification Method", which will not be described here. Among them:

[0050] The steps for setting up the gasification unit furnace in sequence are:

[0051] Step 1: see figure 2 , first estab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com