Double-layer impact-proof assembled steel structure truss steel bar processing anti-smashing shed

A steel bar processing and anti-collision technology, which is applied to truss structures, structural elements, and elongated structural members for load-bearing. High requirements and other problems, to achieve the effect of good anti-smashing and anti-impact effect, reasonable structural design force, flexible and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment:

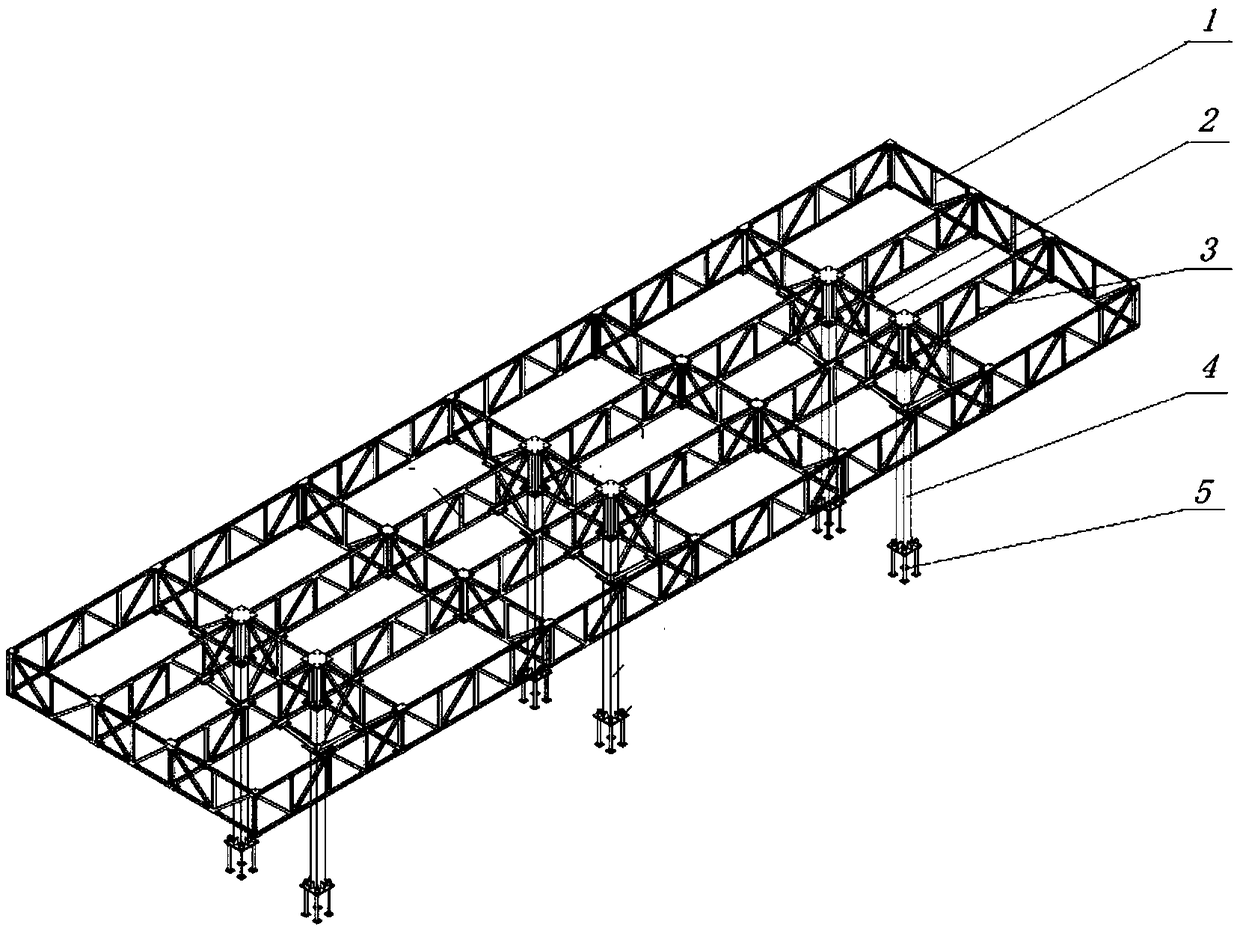

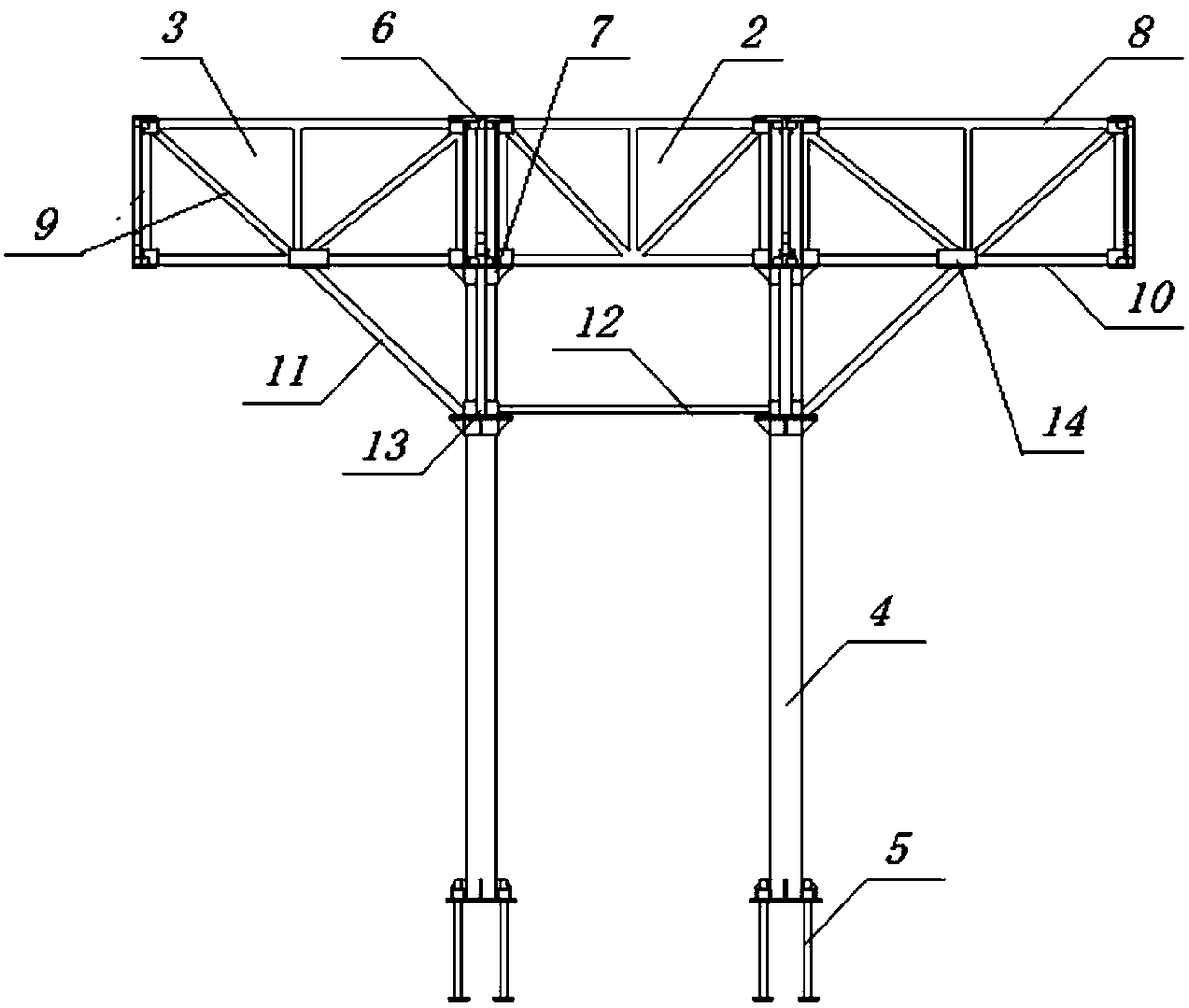

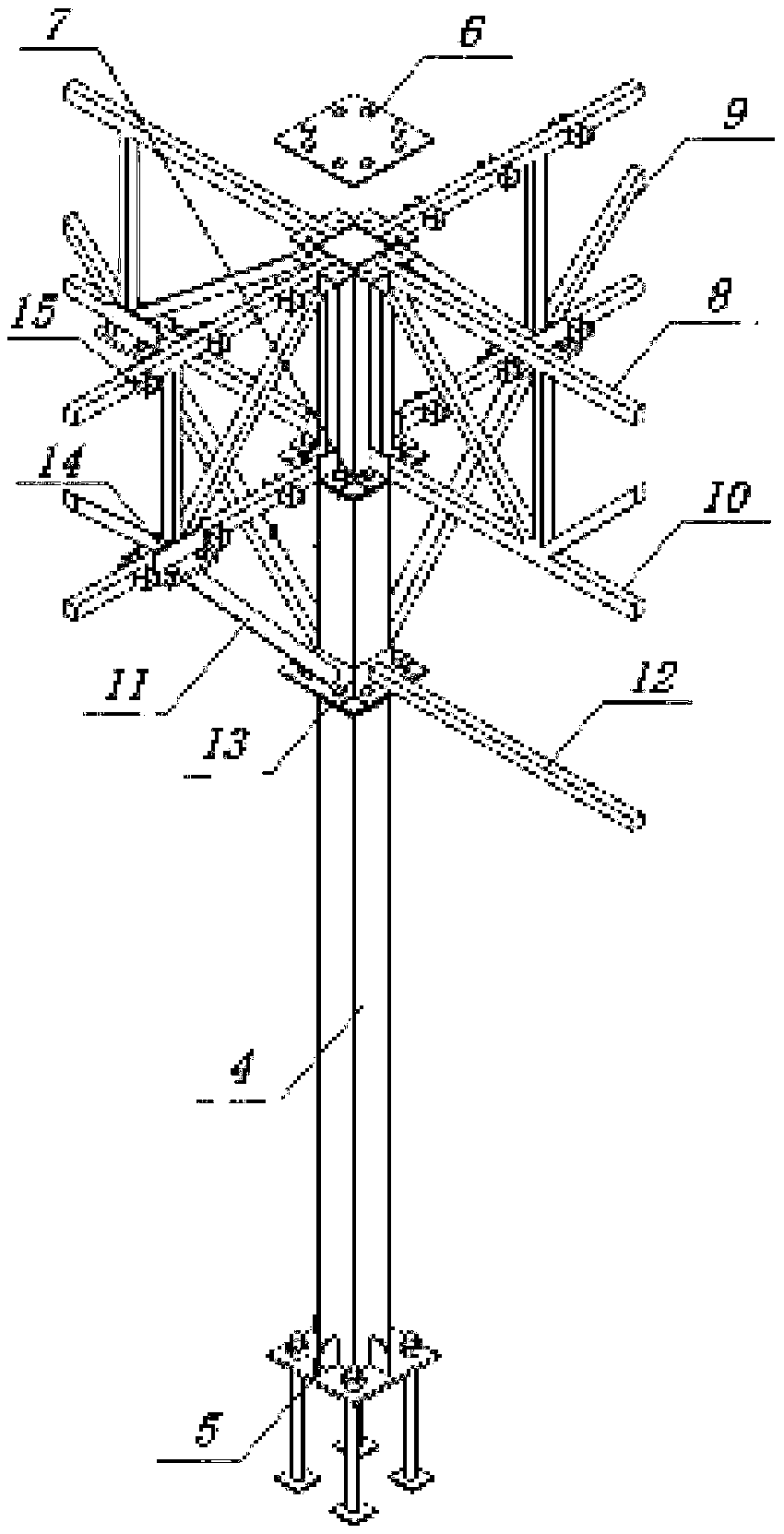

[0020] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention includes a support unit, the support unit includes two square tube columns 4 and a support frame, and a column foot 5 with embedded parts is arranged at the lower end of the square tube column 4; The inter-column trusses 2 between the upper ends of the square tube columns 4 are evenly connected and arranged on the remaining three sides of the upper end of each square tube column 4, and three inner trusses 3 are arranged around the outer circumference of the six inner trusses 3, which are composed of four outer trusses 1 In the rectangular frame, the inner truss 3 is connected with the rectangular frame, the inner truss 3, the outer truss 1, and the inter-column truss 2 form a grid shape, and the inner truss 3, the outer truss 1, and the inter-column truss 2 all include truss upper chords 8, The truss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com