Vegetable and fruit antibacterial fresh-keeping wrapping paper

A fresh-keeping packaging, vegetable and fruit technology, applied in the field of vegetable and fruit packaging, can solve the problems of poor fresh-keeping effect, fresh-keeping packaging materials are not healthy and environmentally friendly, etc., to achieve good plant sterilization inhibition, inhibition of bacterial growth and prevention, good antibacterial effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

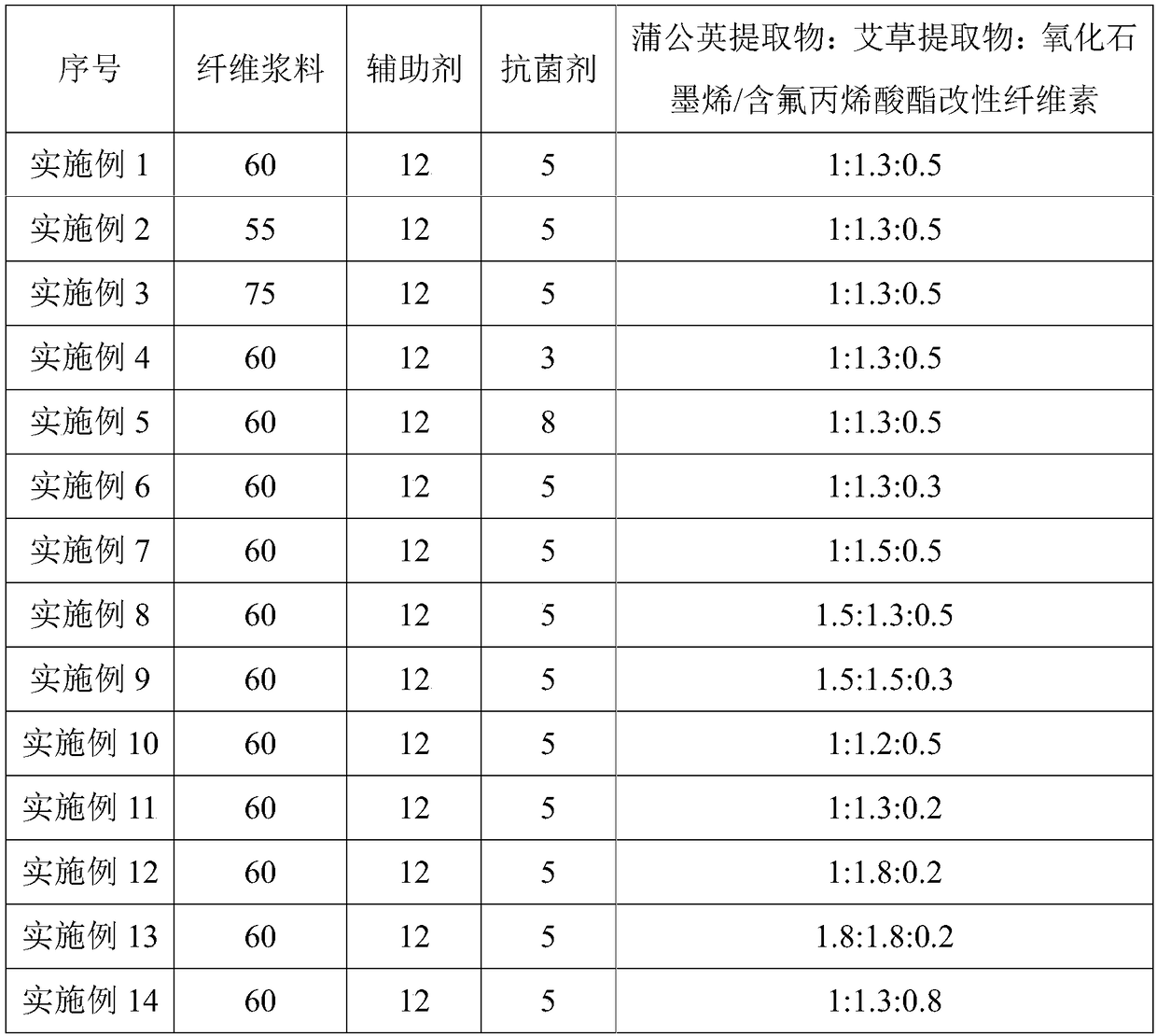

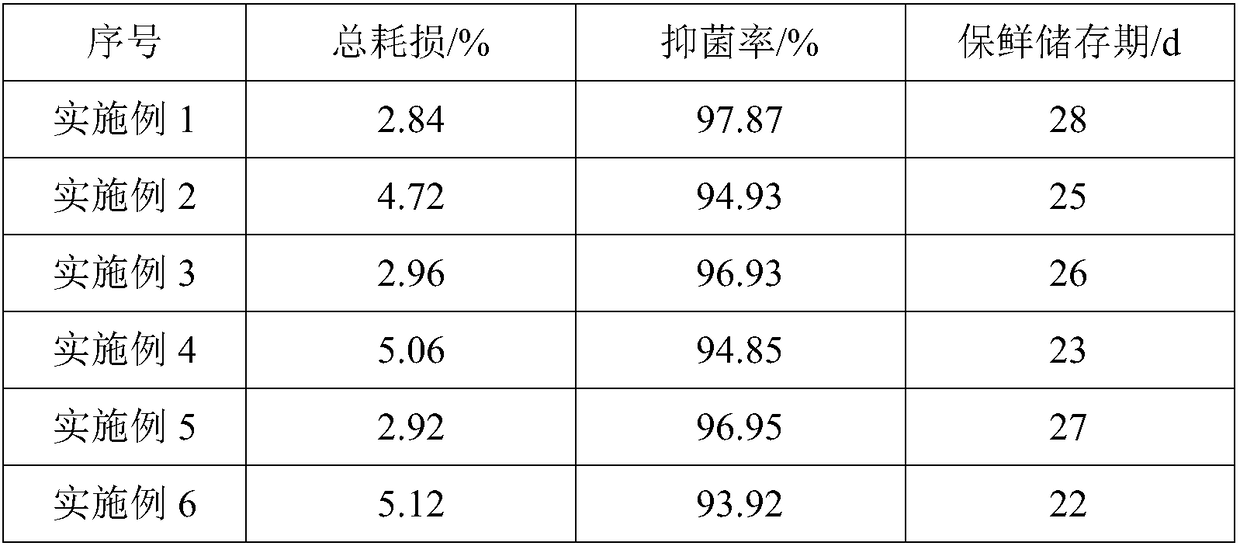

[0028] An antibacterial and fresh-keeping wrapping paper for vegetables and fruits, which is prepared from the following components by mass, and the specific components and contents are shown in Table 1 below. The fiber pulp includes coniferous wood pulp and secondary fibers, and the mass ratio of coniferous wood pulp and secondary fibers is 20:10.

[0029] The preparation steps of the vegetable and fruit antibacterial and fresh-keeping wrapping paper are:

[0030] Mix and beat the raw material fibers until the freeness of the pulp is 250-280CSF, raise the temperature to 80°C, add auxiliary agents, and send them to the headbox after deslagging, dispersing and screening, and form them through the forming net;

[0031] After the slurry forming net is formed, the antibacterial agent is added by coating method between front and rear drying, and fresh-keeping wrapping paper is obtained after drying and calendering.

[0032] Table 1

[0033]

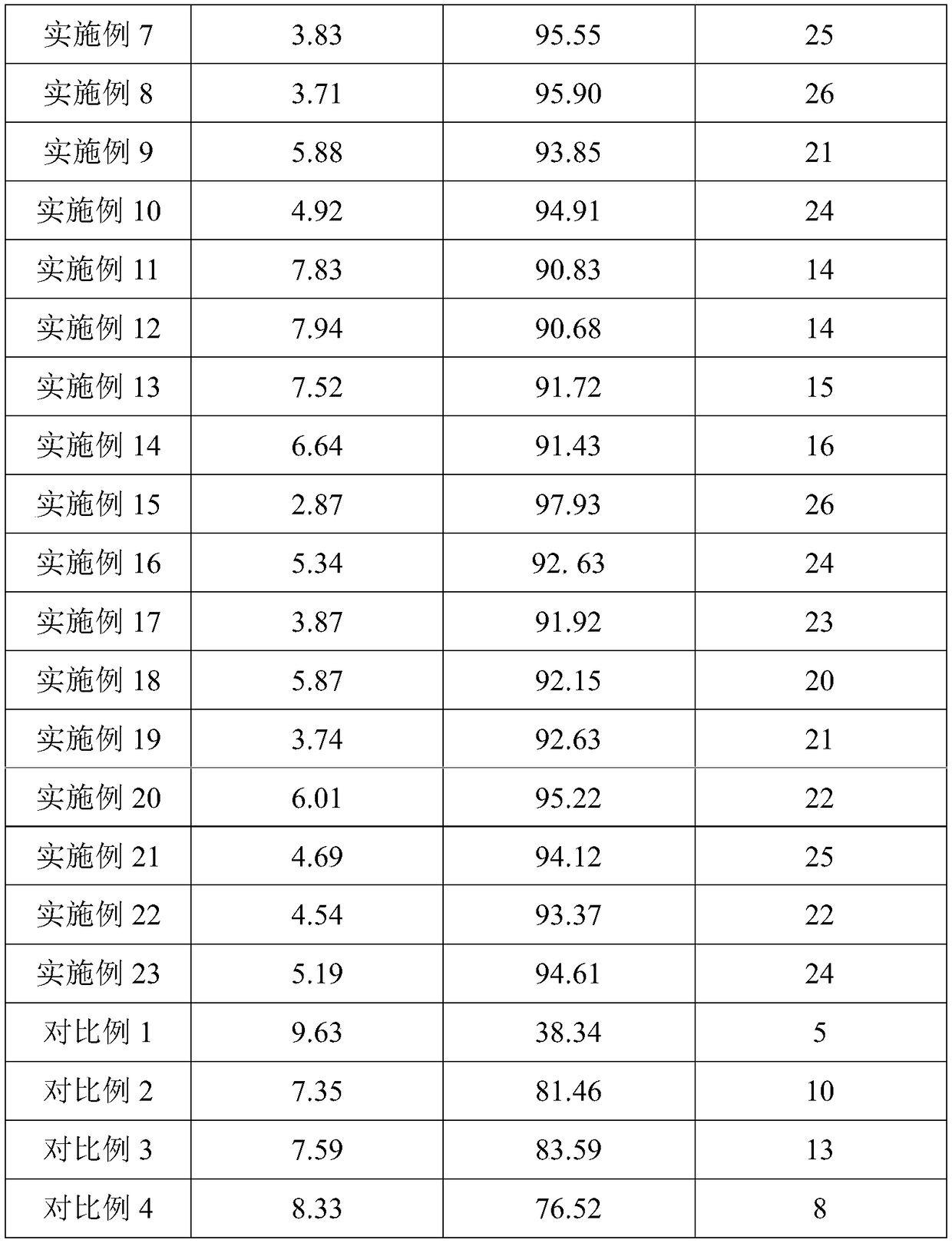

Embodiment 15~23

[0035] A vegetable and fruit antibacterial and fresh-keeping packaging paper, its component raw materials and preparation method are the same as in Example 1, wherein the preparation method of graphene oxide / fluorine-containing acrylate modified cellulose in the antibacterial agent is as follows:

[0036] S1. Preparation of fluorine-containing acrylate modified cellulose: Mix emulsifier, water and fluorine-containing acrylate monomer to pre-emulsify, add cellulose solution and initiator under inert gas conditions, polymerize and synthesize modified cellulose, and polymerize The temperature is 60°C, the polymerization time is 6 hours, the emulsifier is sodium lauryl sulfate, and the initiator is potassium persulfate;

[0037] S2. Preparation of graphene oxide / fluorine-containing acrylate modified cellulose: Prepare a mixed solution of strong alkali, urea and thiourea, cool to -10~-20°C, stir and add the modified cellulose in S1 and evenly dispersed Graphene oxide solution, keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com