Electrostatic spinning device

A technology of electrospinning and driving device, which is applied in the direction of textile and paper making, filament/thread forming, fiber processing, etc., to achieve the effect of reducing the starting voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below by means of the accompanying drawings and examples.

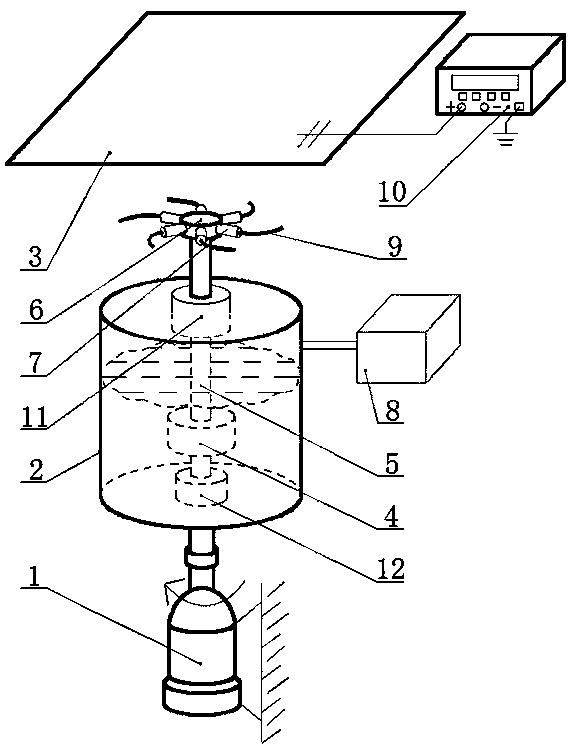

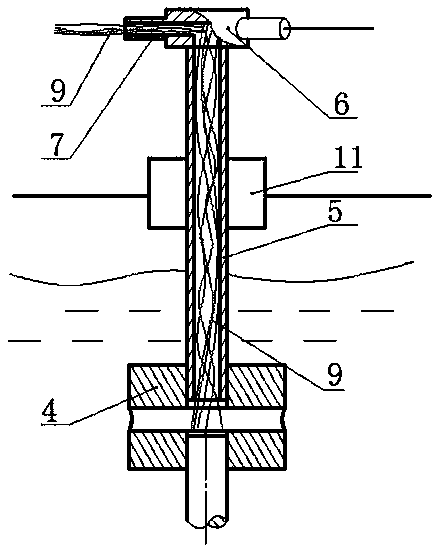

[0024] like figure 1 Shown: an electrospinning device, including a driving device 1, a liquid inlet coupling 4, a liquid passing shaft 5, a solution tank 2, a rotating head 6, a plurality of spinnerets 7, an air pump 8, a collector 3, an induction Rope 9, high voltage power supply 10. The driving device 1 is composed of a driving motor, a shaft coupling, and a rotating shaft. The output speed range of the driving device 1 is 30rpm~1000rpm. A high-voltage power supply 10 is connected to the device 3, and the output voltage value of the high-voltage power supply 10 is 1kV~50kV. By adjusting the output value of the high-voltage power supply 10, the distance between the collector 3 and the spinneret 7, the solubility of the spinning solution, and the temperature of the air pump 8 Electrospinning process parameters such as pressure can further adjust and control the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com