Tin selenide thin film and preparation method thereof

A technology of tin selenide and thin films, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problems of low preparation cost, lack of preparation of high-quality tin selenide thin films, etc., and achieves low requirements for equipment and high production efficiency , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

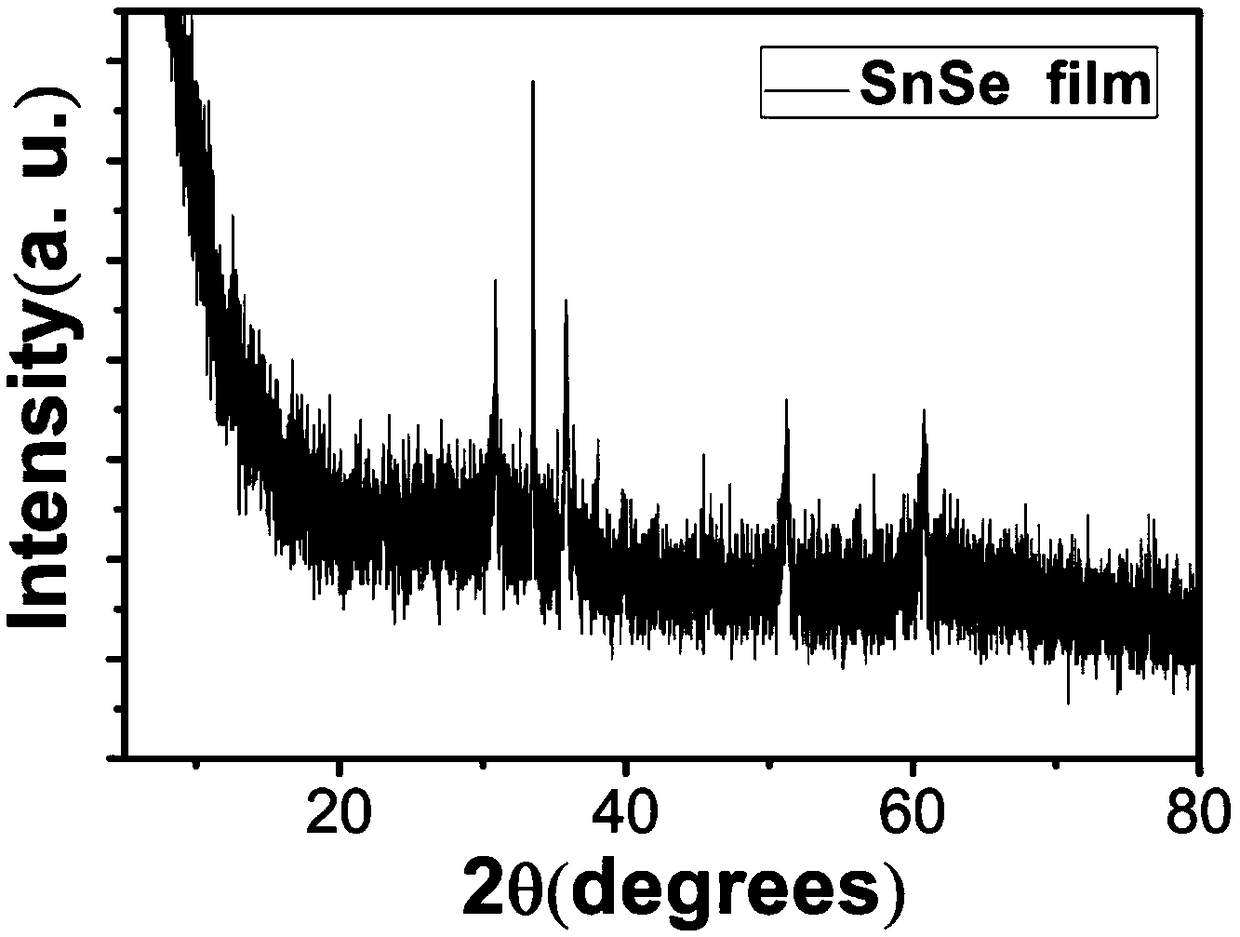

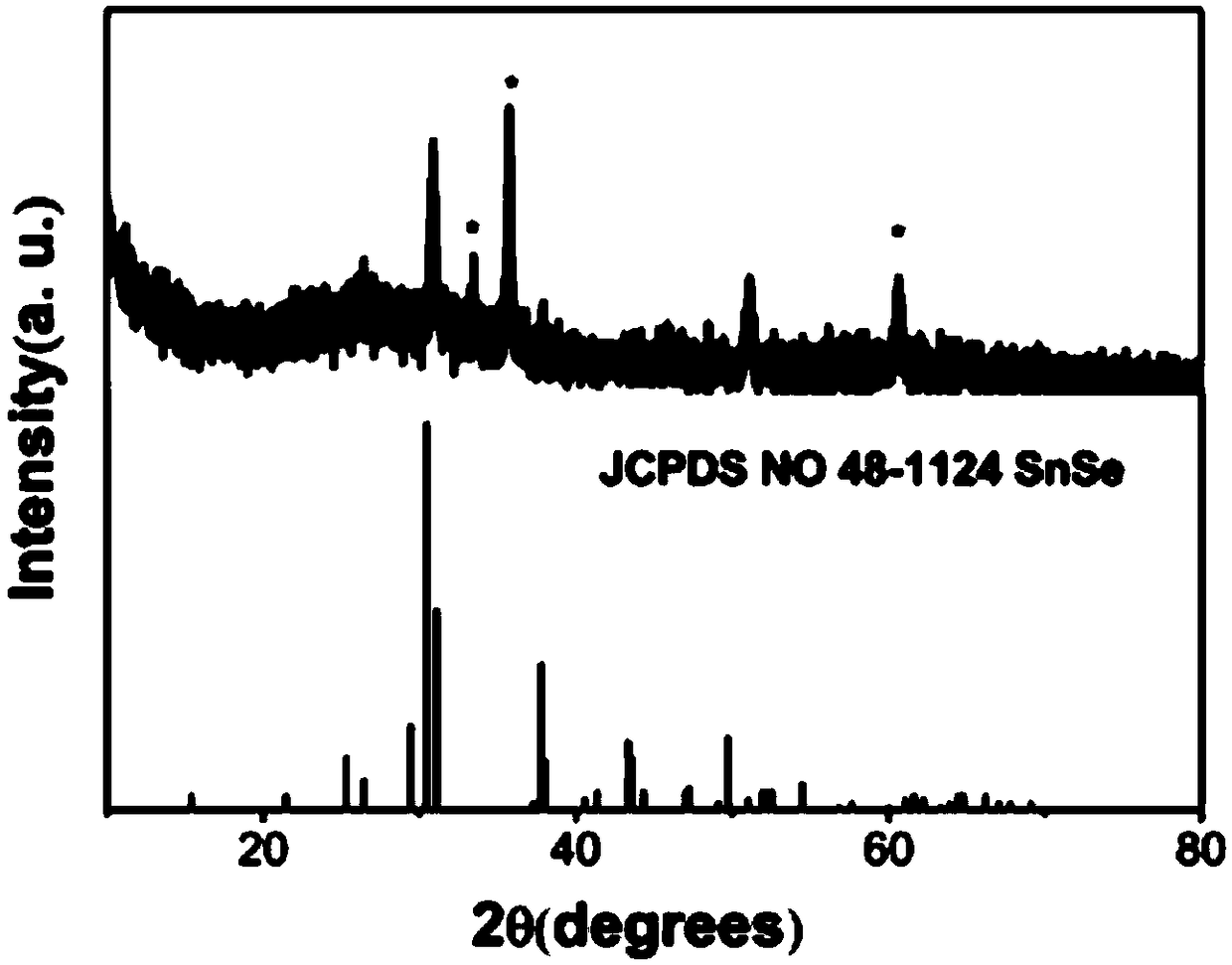

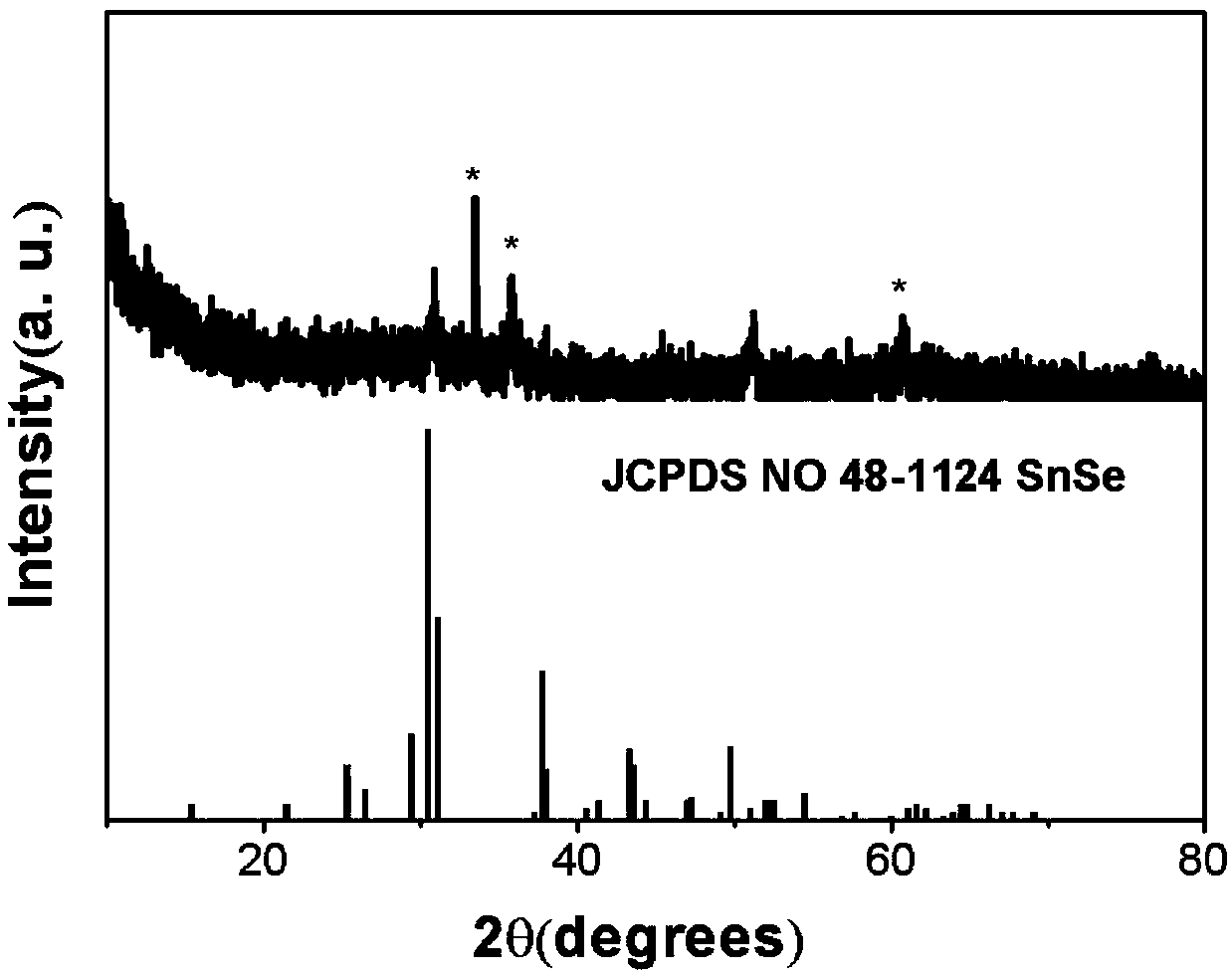

Image

Examples

Embodiment 1

[0041] A tin selenide thin film is prepared by electrodeposition on an ITO substrate by an electrochemical method. Its preparation method specifically comprises the following steps:

[0042] (1) Weigh 10mg of SnSe powder into 30ml of acetone, and use an ultrasonic cleaner to vibrate ultrasonically for 15min~20min to form a dark brown suspension;

[0043] (2) Pour the suspension evenly into two centrifuge tubes, put it into a centrifuge and centrifuge at a speed of 5000 r / min, and take the supernatant into a 50 mL beaker after centrifugation;

[0044] (3) Weigh 3 mg of iodine powder and add it to the supernatant obtained after centrifugation, and sonicate for 15-20 minutes, so that the iodine powder particles are fully dispersed in acetone to obtain a suspension of SnSe powder and iodine;

[0045] (4) Connect the ITO substrate on which the SnSe film needs to be deposited to the negative pole of the DC stabilized power supply, connect the metal titanium sheet to the positive po...

Embodiment 2

[0049] A tin selenide thin film is prepared by electrodeposition on an ITO substrate by an electrochemical method. Its preparation method specifically comprises the following steps:

[0050] (1) Weigh 20 mg of SnSe powder into 80 mL of acetone, and use an ultrasonic cleaner to vibrate ultrasonically for 15-20 min to form a dark brown suspension;

[0051] (2) Pour the suspension evenly into two centrifuge tubes, put it into a centrifuge for centrifugation, and the speed of the centrifuge is 2000 ~ 5000 r / min. After centrifugation, take the supernatant into a 50 mL beaker;

[0052] (3) Weigh 4 mg of iodine powder into the supernatant obtained after centrifugation and sonicate for 15-20 minutes to fully disperse the iodine powder particles in acetone to obtain a suspension of SnSe powder and iodine;

[0053] (4) Connect the ITO substrate on which the SnSe film needs to be deposited to the negative pole of the DC stabilized power supply, connect the metal titanium sheet to the po...

Embodiment 3

[0057] A tin selenide thin film is prepared by electrodeposition on an ITO substrate by an electrochemical method. Its preparation method specifically comprises the following steps:

[0058] (1) Weigh 30 mg of SnSe powder into 100 mL of acetone, and use an ultrasonic cleaner to vibrate ultrasonically for 15-20 min to form a dark brown suspension;

[0059] (2) Pour the suspension evenly into two centrifuge tubes, put it into a centrifuge for centrifugation, and the speed of the centrifuge is 2000 ~ 5000 r / min. After centrifugation, take the supernatant into a 50 mL beaker;

[0060] (3) Weigh 10 mg of iodine powder, 3 mg of potassium iodide and 5 mg of sodium bicarbonate and add them to the supernatant obtained after centrifugation and sonicate for 15-20 min to fully disperse the iodine powder particles in acetone to obtain the mixture of SnSe powder and iodine Suspension; adjust the pH of the suspension to 8.5-9; (due to the limitation of precision, this range is fine)

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com