5A12 aluminum alloy cast ingot as well as production method and application thereof

An aluminum alloy ingot, 5A12 technology, applied in the field of alloy processing, can solve the problems of complex wide casting technology and high technical requirements, and achieve the effects of good internal structure, large flow rate and good plasticity of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

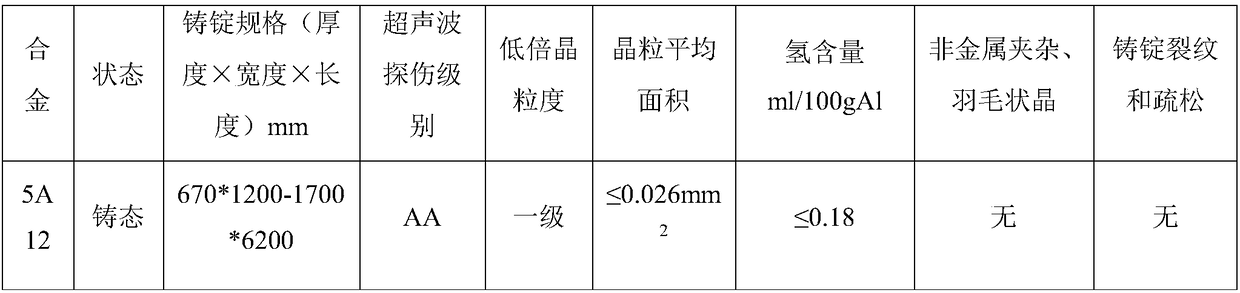

Image

Examples

Embodiment 1

[0031] The 5A12 aluminum alloy ingot of the present invention, the mass percent content of each alloy element in the 5A12 aluminum alloy ingot is: Si≤0.15%, Fe 0.15%, Cu≤0.05%, Mn 0.55%, Mg 9.0%, Cr≤0.1 %, Ni≤0.1%, Zn≤0.1%, Ti 0.08%, Be 0.0015%, Sb 0.02%, other impurity elements <0.05%, and the balance is Al;

Embodiment 2

[0033] The 5A12 aluminum alloy ingot of the present invention, the mass percent content of each alloy element in the 5A12 aluminum alloy ingot is: Si≤0.15%, Fe 0.2%, Cu≤0.05%, Mn 0.6%, Mg 9.3%, Cr≤0.1 %, Ni≤0.1%, Zn≤0.1%, Ti 0.07%, Be 0.002%, Sb 0.015%, other impurity elements <0.05%, and the balance is Al;

Embodiment 3

[0035] The 5A12 aluminum alloy ingot of the present invention, the mass percent content of each alloy element in the 5A12 aluminum alloy ingot is: Si≤0.15%, Fe 0.1%, Cu≤0.05%, Mn 0.5%, Mg 8.8%, Cr≤0.1 %, Ni≤0.1%, Zn≤0.1%, Ti 0.09%, Be 0.001%, Sb 0.01%, other impurity elements <0.05%, and the balance is Al;

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com