A high-strength, high-conductivity, heat-resistant cu-fe-y-mg alloy material with electromagnetic wave shielding performance and its preparation method

A cu-fe-y-mg, shielding performance technology, applied in the field of copper alloy processing, can solve the problems of alloy processing energy, uneven product structure and performance, uneven iron and other problems, achieve high strength and high conductivity, good processing performance The effect of high distortion energy storage and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

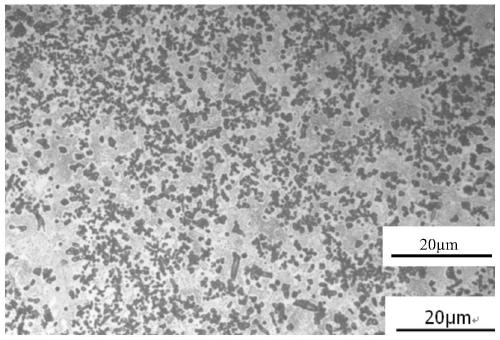

Embodiment 1

[0043] The composition is Fe 20.0wt%, Mg 0.1wt%, Y 0.1wt%, Zr 0.05wt%, Sr 0.06wt%, and the balance is Cu. Prepared as follows: Melting: with electrolytic pure copper, 40wt% Fe master alloy, Cu-13wt% Zr master alloy, Cu-15wt% Y master alloy, Cu-15wt% Sr and Cu-25wt% Mg master alloy as raw materials, According to the composition ratio of the designed copper alloy material, the master alloy composition; first melt the electrolytic pure copper, add Cu-40wt% Fe master alloy according to the iron content of 0.5wt%, put it into the furnace for melting, and the melting temperature is 1250-1270℃ , after melting, add the remaining Cu-40wt% Fe master alloy, the melting temperature is 1480-1500 ° C, after melting Cu-13wt% Zr master alloy, Cu-15wt% Y master alloy, Cu-15wt% Sr master alloy and Cu-25wt% %Mg master alloy, melted under the protection of nitrogen. During the smelting process, the covering agent is cryolite + sodium carbonate + calcium carbonate + fluorite + coke borax (cryolit...

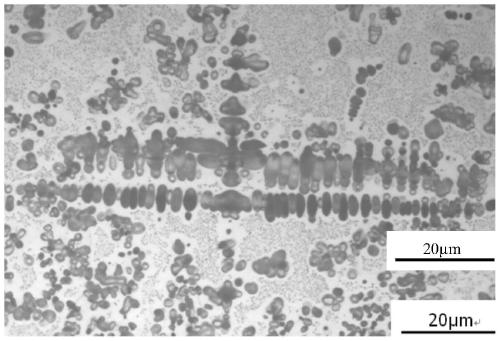

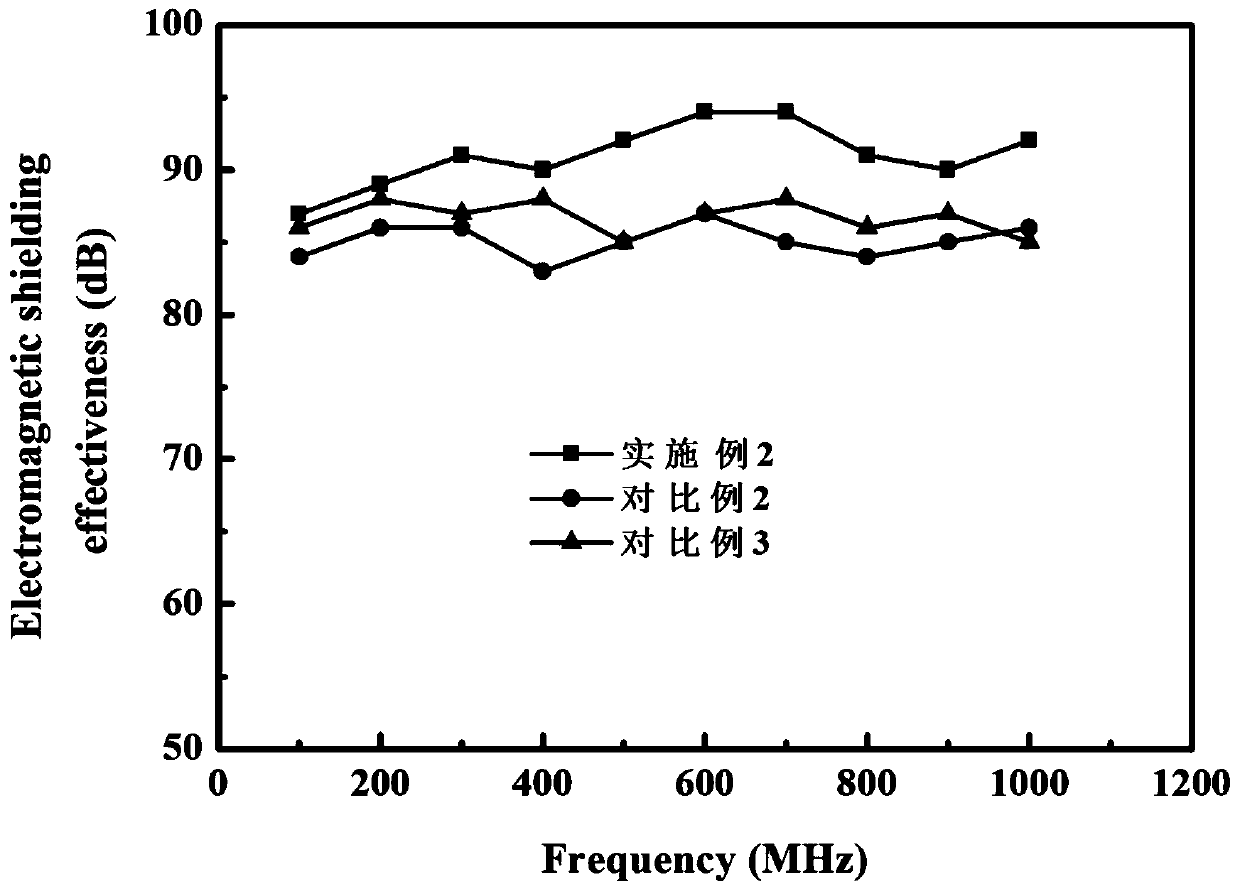

Embodiment 2

[0048] The composition is Fe 20.0wt%, Mg 0.1wt%, Y 0.1wt%, Zr 0.05wt%, Sr 0.06wt%, and the balance is Cu. Prepared as follows: Melting: with electrolytic pure copper, 40wt% Fe master alloy, Cu-13wt% Zr master alloy, Cu-15wt% Y master alloy, Cu-15wt% Sr and Cu-25wt% Mg master alloy as raw materials, According to the composition ratio of the designed copper alloy material, the master alloy composition; first melt the electrolytic pure copper, add the Cu-40wt% Fe master alloy according to the iron content of 0.5wt%, and put it into the furnace for melting; the melting temperature is 1250-1270°C , after melting, add the remaining Cu-40wt% Fe master alloy, the melting temperature is 1480-1500 ° C, after melting Cu-13wt% Zr master alloy, Cu-15wt% Y master alloy, Cu-15wt% Sr master alloy and Cu-25wt% %Mg master alloy, melted under the protection of nitrogen. During the smelting process, the covering agent is cryolite + sodium carbonate + calcium carbonate + fluorite + coke borax (cr...

Embodiment 3

[0056] The composition is Fe 10.0wt%, Mg 0.1wt%, Y 0.1wt%, Zr 0.05wt%, Sr 0.06wt%, and the balance is Cu. Prepared as follows: Melting: with electrolytic pure copper, 40wt% Fe master alloy, Cu-13wt% Zr master alloy, Cu-15wt% Y master alloy, Cu-15wt% Sr and Cu-25wt% Mg master alloy as raw materials, According to the composition ratio of the designed copper alloy material, the master alloy composition; first melt the electrolytic pure copper, add the Cu-40wt% Fe master alloy according to the iron content of 0.5wt%, and put it into the furnace for melting; the melting temperature is 1250-1270°C , after melting, add the remaining Cu-40wt% Fe master alloy, the melting temperature is 1420-1450 ° C, after melting Cu-13wt% Zr master alloy, Cu-15wt% Y master alloy, Cu-15wt% Sr master alloy and Cu-25wt% %Mg master alloy, melted under the protection of nitrogen. During the smelting process, the covering agent is cryolite + sodium carbonate + calcium carbonate + fluorite + coke borax (cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com