Method for comprehensive utilization of titanium concentrate

A titanium concentrate, a comprehensive technology, applied in the field of comprehensive utilization of titanium concentrate, can solve the problems of many impurities, waste, low-grade titanium-rich materials, etc., and achieve high quality, significant economic and social value, good economic benefits and application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

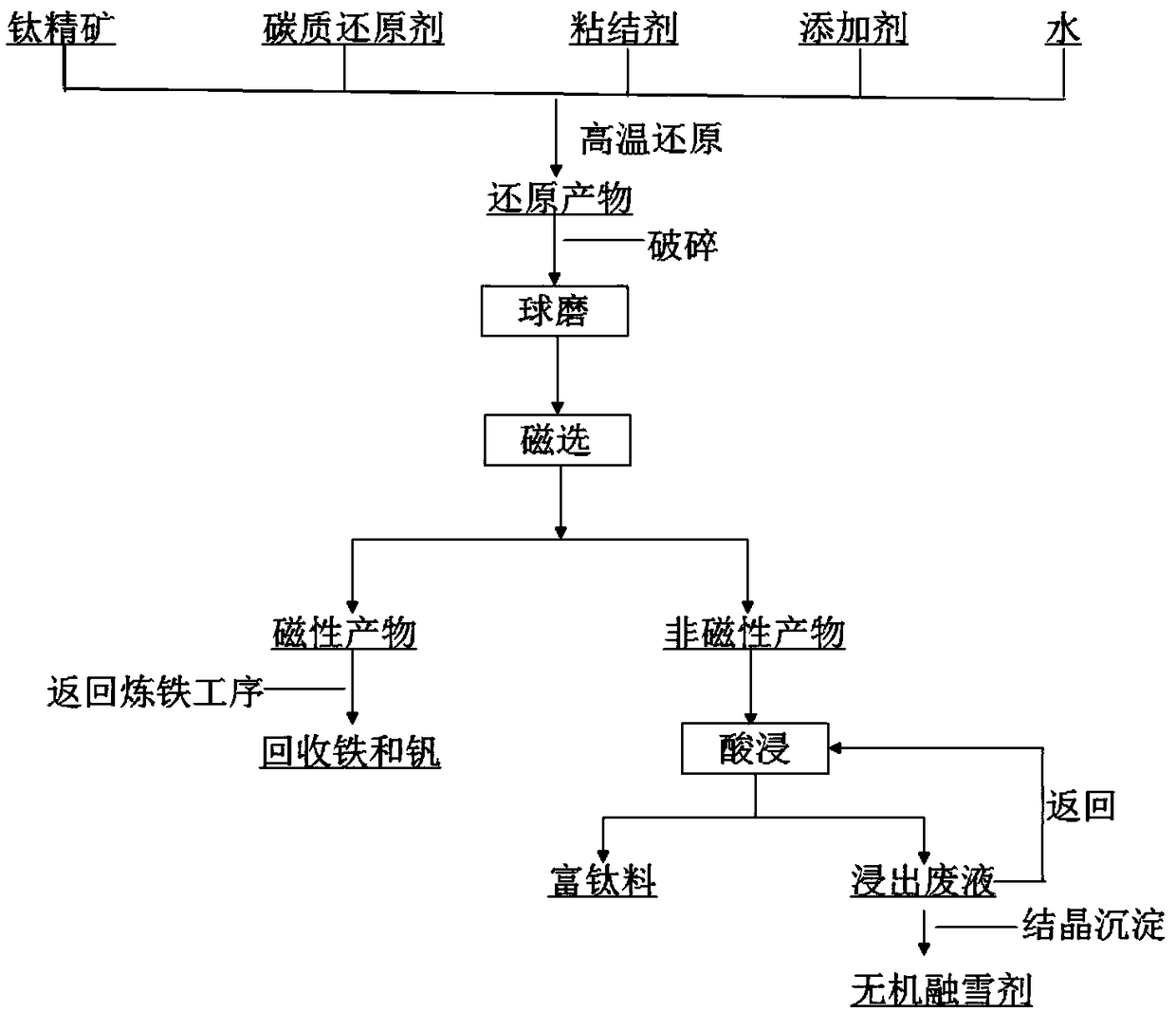

[0048] Such as figure 1 As shown, the present embodiment prepares the titanium-rich material applicable to the titanium-rich material of the boiling chlorination method according to the following method:

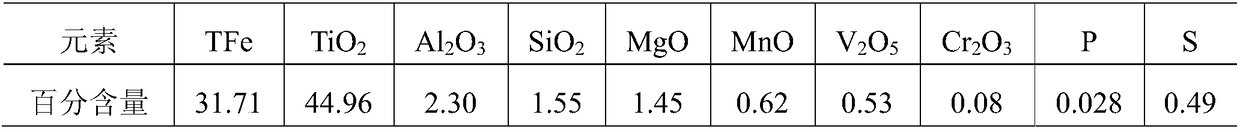

[0049] (1) Take 10g titanium concentrate, grind it to pass through -80 mesh sieve, mix it with 1.79g graphite, 0.71g starch, 0.3g anhydrous sodium carbonate and 0.5ml water to make pellets;

[0050] (2) Place the obtained pellets in a rotary kiln, raise the temperature to 1000° C. to reduce the pellets for 5 hours, and quench the reduction product in water after the reaction to obtain a mixed material;

[0051] (3) The mixed material is crushed, and ball milled into a particle diameter of -200 mesh fine powder, magnetically separated under a magnetic field strength of 70mT to obtain a magnetic product and a non-magnetic product;

[0052] (4) The obtained magnetic product is used as a coolant for extracting vanadium from vanadium-containing molten iron; the magnetic product ...

Embodiment 2

[0055] (1) Take 10g of titanium concentrate, grind it to pass through a -200 mesh sieve, mix it with 2.24g of graphite, 0.37g of starch, 0.3g of anhydrous sodium carbonate and 0.6ml of water to make pellets;

[0056] (2) Place the obtained pellets in a rotary kiln, raise the temperature to 1250° C., and reduce the pellets for 4 hours. After the reaction is completed, the reduction product is cooled by water quenching to obtain a mixed material;

[0057] (3) The mixed material is crushed, and ball milled into a particle diameter of -200 mesh fine powder, magnetically separated under a magnetic field strength of 35mT to obtain a magnetic product and a non-magnetic product;

[0058] (4) The obtained magnetic product is used as a coolant for extracting vanadium from molten iron containing vanadium; the magnetic product is acid-leached at 60°C for 4 hours by hydrochloric acid with an initial concentration of 4mol / L, and the liquid-solid ratio of hydrochloric acid to non-magnetic pro...

Embodiment 3

[0061] (1) Take 10g of titanium concentrate, grind it to pass through a -120 mesh sieve, mix it with 3.36g of petroleum coke, 0.67g of starch, 0.1g of anhydrous sodium carbonate and 0.8ml of water to make pellets;

[0062] (2) Place the obtained pellets in a rotary kiln, raise the temperature to 1200° C. to reduce the pellets for 2 hours, and quench the reduction product in water after the reaction to obtain a mixed material;

[0063] (3) The mixed material is crushed, and ball milled into a particle diameter of -400 mesh fine powder, magnetically separated under a magnetic field strength of 100mT to obtain a magnetic product and a non-magnetic product;

[0064] (4) The obtained magnetic product is used as a coolant for extracting vanadium from molten iron containing vanadium; the magnetic product is acid-leached at 30° C. for 3 hours by hydrochloric acid with an initial concentration of 2mol / L, and the liquid-solid ratio of hydrochloric acid to non-magnetic product is 8:1, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com