Water gate dipper type shunting energy dissipating rushing-proof technology

A technology for energy dissipation and energy dissipation of undercurrents, applied in water conservancy projects, marine engineering, coastline protection, etc. problems, to achieve the effect of less engineering, good economic benefits and application prospects, and reduced excavation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

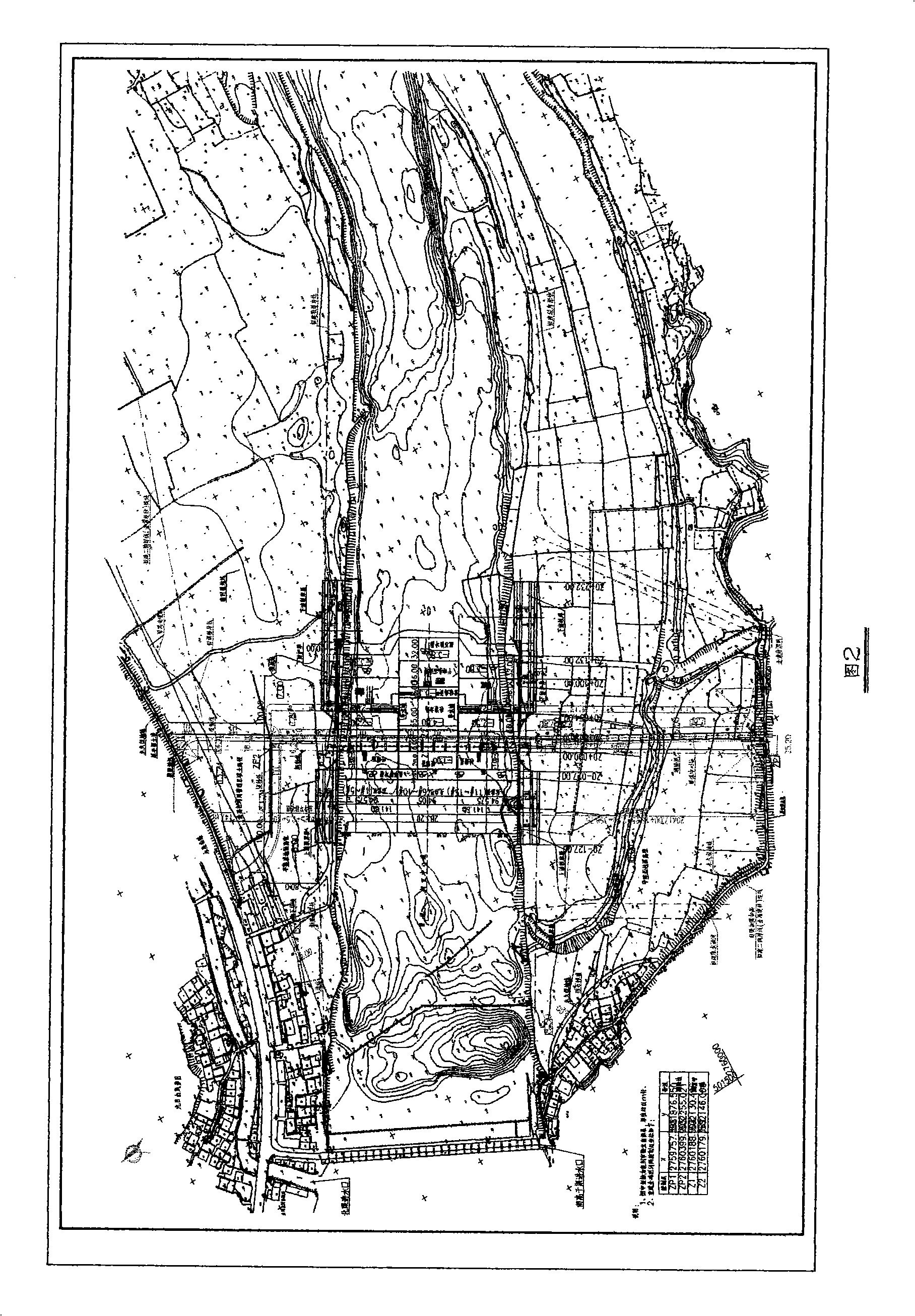

Embodiment 1

[0038] like figure 1 The curve 1 of the upstream surface of the bucket type diverter pier shown is designed as:

[0039] A cylindrical surface with a radius of 3.1m;

[0040] The design of pier top 2 is:

[0041] The upper bottom is 2.7m long, the lower bottom is 3.5m long, and the horizontal trapezoidal shape is 0.622m high;

[0042] Pier bottom 3 is designed as:

[0043] The slope section of 1:4 is connected with the horizontal section of the stilling pool.

[0044] The pier back water surface 4 is designed as:

[0045] A vertical rectangular shape with a width of 3.5m and a height of 2.88m or 3.28m;

[0046] The sluice gate 5 is a wide 8.5m, and a height is a flat steel gate of 7.5m;

[0047] Gate pier 6 is a cuboid with a length of 18m and a thickness of 2.5m, and two ends are columns with a radius of 1.25m;

[0048] The stilling pool 7 is a 1:4 slope surface on one side and a deep 3.2m pool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com