High temperature-resistant high strength stainless steel plate for hearth plate and production method

A technology of stainless steel plate and production method, which is applied in the field of special steel, can solve the problems of not being able to fundamentally guarantee the high-level mechanical properties of the heat-resistant stainless steel furnace bottom plate, increasing the direct cost and time cost of production, and the difficulty of large-scale promotion. , to achieve the effect of reducing the tendency of crack formation, improving creep resistance and durability, and reducing the content of harmful inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

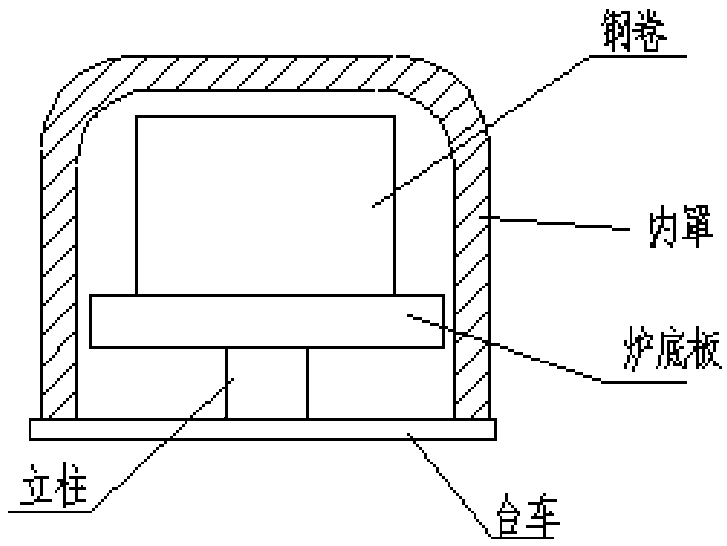

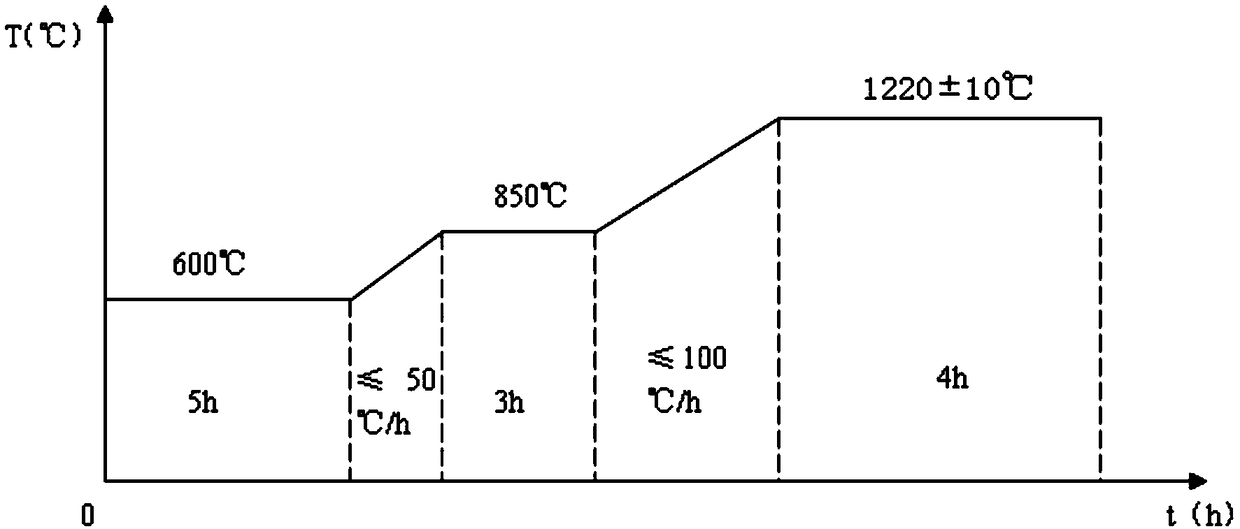

[0032] A high-temperature resistant high-strength stainless steel plate for the bottom plate of a furnace. The production process includes: smelting by a composite blowing method of electric furnace + oxygen lance blowing oxygen, adding lime, fluorite and dephosphorization agent, and performing deep dephosphorization. The tapping temperature is at 1655°C. Then use the LF furnace for refining, add various alloys in the LF furnace, adjust the alloy, add lime and fluorite, and carry out deep desulfurization; add Al powder for deoxidation; the whole process of the LF furnace uses bottom blowing nitrogen to increase nitrogen. At the VD station, a high vacuum of 670Pa is used for 20 minutes. After the vacuum is broken, FeTi and carbonized rice husk are added, and softly blown for 10 minutes (Ar:N is controlled at 2:1), followed by molding. After the steel ingot is demolded and cooled slowly, it is annealed, the cap and the bottom of the ingot are sawed off, the surface of the steel ...

Embodiment 2

[0034] A high-temperature resistant high-strength stainless steel plate for the bottom plate of a furnace. The production process includes: smelting by a composite blowing method of electric furnace + oxygen lance blowing oxygen, adding lime, fluorite and dephosphorization agent, and performing deep dephosphorization. The tapping temperature is at 1671°C. Then use the LF furnace for refining, add various alloys in the LF furnace, adjust the alloy, add lime and fluorite, and carry out deep desulfurization; add Al powder for deoxidation; the whole process of the LF furnace uses bottom blowing nitrogen to increase nitrogen. At the VD station, a high vacuum of 1330Pa is used for 20 minutes. After the vacuum is broken, FeTi and carbonized rice husk are added, and softly blown for 10 minutes (Ar:N is controlled at 2:1), followed by molding. After the steel ingot is demolded and cooled slowly, it is annealed, the cap and the bottom of the ingot are sawed off, the surface of the steel...

Embodiment 3

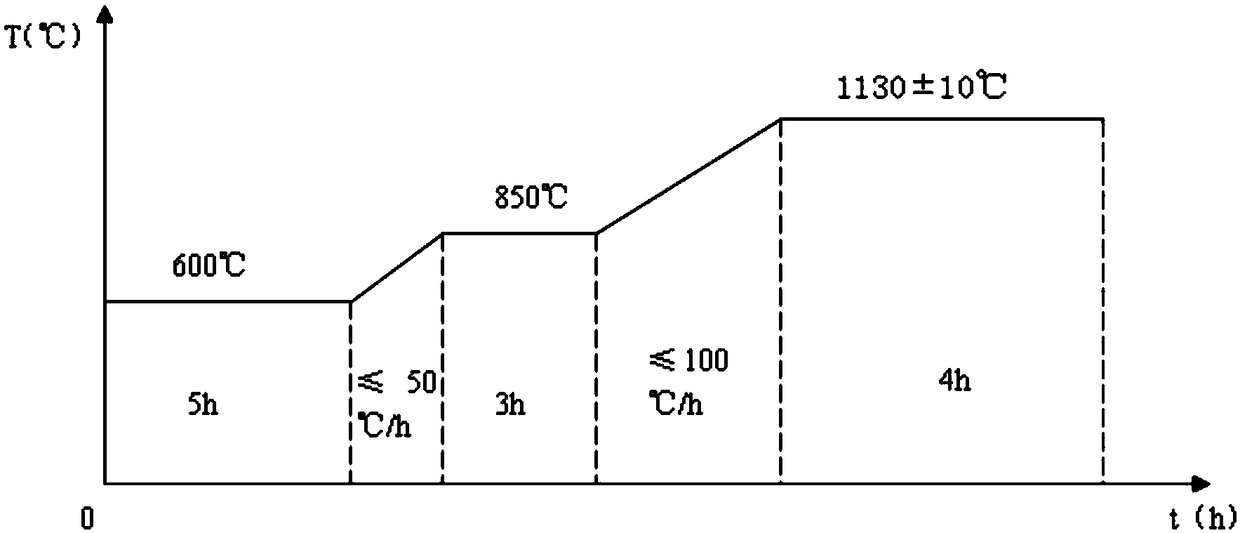

[0036] A high-temperature resistant high-strength stainless steel plate for the bottom plate of a furnace. The production process includes: smelting by a composite blowing method of electric furnace + oxygen lance blowing oxygen, adding lime, fluorite and dephosphorization agent, and performing deep dephosphorization. The tapping temperature is at 1681°C. Then use the LF furnace for refining, add various alloys in the LF furnace, adjust the alloy, add lime and fluorite, and carry out deep desulfurization; add Al powder for deoxidation; the whole process of the LF furnace uses bottom blowing nitrogen to increase nitrogen. At the VD station, a high vacuum of 3350Pa is used for 20 minutes. After the vacuum is broken, FeTi and carbonized rice husk are added, and softly blown for 10 minutes (Ar:N is controlled at 1:1), followed by molding. After the steel ingot is demolded and cooled slowly, it is annealed, the cap and the bottom of the ingot are sawed off, the surface of the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com