Cool mouth liquor and preparation method thereof

A cool-mouth-type liquor technology, which is applied in the field of cool-mouth-type liquor and its preparation, can solve the problems of mint-flavored liquor with bitterness, lack of flavor substances of menthyl ester, and high menthol content, so as to increase the cool taste and be suitable for industrialization The effect of simple production and preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The present invention provides a preparation method of the above-mentioned white wine, including the following steps:

[0089] A, alcohol extraction

[0090] Natural plants containing menthol contain alcohol extraction, and concentrate the extract.

[0091] B, esterification reaction

[0092] An additional yellow water is added to the extract concentrated in step a, and the pH is adjusted to be 2 to 6.5, and the esterified enzyme is added to the esterification reaction;

[0093] C, segment distillation

[0094] The solution after esterification reaction was segmented, and the distillation liquid was collected in segments to obtain a base wine having a different amount of mint.

[0095] d, hook

[0096] The raw wine obtained by step c will be hooked as needed to get the cold mouth white wine.

[0097] The present invention employs a natural plant feedstock containing a menthol, an extract containing a menthol, which has a natural mint in natural mint, such as menthol and men...

Embodiment 1

[0166] Example 1 Preparation of cold and mouth white wine in yellow water with strong liquor

[0167] The thick fragrant yellow water was detected by 0.6% acetic acid content.

[0168] The specific steps are as follows:

[0169] A, raw material preparation

[0170] Pulling the mint leaflets 3 times, drained, and the homogeneous shining machine is pulverized, and the sieve is 10 sieves;

[0171] B, alcohol extraction

[0172] The homogenate was stirred in a volume ratio of 1: 3, and the extraction tank was mixed with eating alcohol (95% v / v). After 24 hours of normal temperature (25 ° C), after filtration, the residue was filtered and then used in a 5-volume eating alcohol ( 95% v / v) Extraction 12 hours of normal temperature (25 ° C);

[0173] C, concentrated extract

[0174] The extract was combined with a vacuum to reduce the distillation under 60 ° C, and the extract was concentrated under 60 ° C.

[0175] D, esterification reaction

[0176] The concentrate and yellow water ...

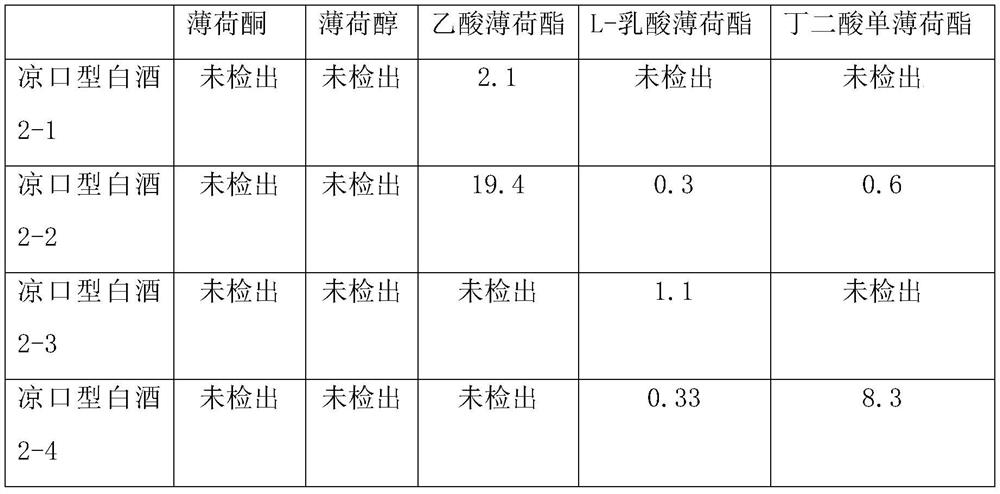

Embodiment 2

[0187] Example 2 Preparation of cold and white wine by yellow water with sauce

[0188] The sauce type of yellow water was detected by 0.8% acetic acid content.

[0189] The specific steps are as follows:

[0190] A, raw material preparation

[0191] The pulverizer is pulverized with a pulverizer, and a 5-point sieve;

[0192] B, alcohol extraction

[0193] The pulverized mint leaves were mixed according to the mass ratio of 1: 20 solid fermented liquor (68% v / v) to mix the extraction tank, heated to 60 ° C, extract for 2 hours; filtered residue, then use 10 times volume solid state Fermentation liquor extracts 2 times under the conditions of the same temperature and time;

[0194] C, concentrated extract

[0195] The extract was combined with 3 extracts, and concentrated with a film concentrator, concentrated under 60 ° C, concentrated extract, and concentrated the extract to a meantol concentration of 15.6%, and the amount concentration of the corresponding substance was 1 m; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com