Concentrated washing powder and preparation method thereof

A technology for concentrating washing powder and detergent, applied in chemical instruments and methods, detergent compositions, detergent compounding agents, etc., can solve the problems of large amount of use, poor cleaning effect, excessive washing powder alkali, etc., and reduce the use of amount, increased wetting effect, high surface activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

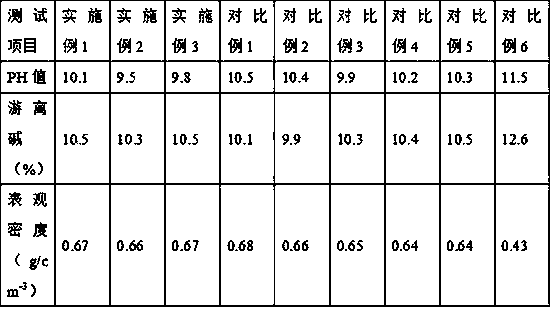

Examples

preparation example Construction

[0030] A preparation method of concentrated washing powder, comprising the steps of:

[0031] In terms of parts by mass, take 8~10 parts of detergent, 3~5 parts of washing aid, 2~4 parts of antibacterial active agent, 2~5 parts of chelating auxiliary agent, 2~4 parts of fabric finishing active agent, 0.2~ 0.5 parts of fluorescent whitening agent CBS, 50~70 parts of water, 0.2~0.4 parts of fatty acid sodium, heated to 40~60°C, stirred and mixed for 20~30min, dried for 5~7h, crushed through 80 mesh sieve, collected sieved particles, and made grains, that is, concentrated washing powder.

Embodiment 1

[0033] Detergent: (1) Add starch to methanol at a mass ratio of 1:10, ultrasonically disperse for 10 minutes, pass through nitrogen protection, heat up to 250°C for 2 hours, filter, take the filtrate and add p-toluenesulfonic acid at a mass ratio of 80:1, Raise the temperature to 110°C, then add 60% iso-octanol of the filtrate quality dropwise, control the dropwise addition time for 20 minutes, keep warm for 1 hour, filter, and take the filtrate a;

[0034] (2) Take the filtrate a and add sodium borohydride at a mass ratio of 40:2, adjust the pH to 8, distill at 140°C and 0.01MPa under reduced pressure to obtain a vacuum distillate, and take the vacuum distillate at a mass ratio of 50:3: 2. Add sodium borohydride and sodium hydroxide solution with a mass fraction of 10% to obtain a mixed solution. Take the mixed solution and add 30% hydrogen peroxide at a mass ratio of 3:2, keep it at 75°C for 2 hours, and adjust the pH to 8. Get the substrate;

[0035] (3) Take alginic acid ...

Embodiment 2

[0043] Detergent: (1) Add starch to methanol at a mass ratio of 2:13, ultrasonically disperse for 13 minutes, pass through nitrogen protection, heat up to 255°C for 3 hours, filter, take the filtrate and add p-toluenesulfonic acid at a mass ratio of 90:2, Raise the temperature to 120°C, then add iso-octanol dropwise with 70% of the filtrate mass, control the dropping time for 25 minutes, keep warm for 1.5 hours, filter, and take the filtrate a;

[0044] (2) Take the filtrate a and add sodium borohydride at a mass ratio of 45:3, adjust the pH to 8.5, and distill under reduced pressure at 145°C and 0.01MPa to obtain a vacuum distillate. Take the vacuum distillate at a mass ratio of 60:4: 5 Add sodium borohydride and sodium hydroxide solution with a mass fraction of 10% to obtain a mixed solution, take the mixed solution and add 30% hydrogen peroxide at a mass ratio of 6:4, keep it warm at 78°C for 2~4h, and adjust the pH to 8.5, get the matrix;

[0045] (3) Take alginic acid an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com