Special novel material for TPU leg guard plate, and preparation method thereof

A leg shield, a new type of technology, applied in the field of sports equipment, can solve the problems affecting the speed of athletes, the shield is bulky, easy to sweat, etc., and achieve the effects of impact resistance, prolonging the service life, and convenient coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

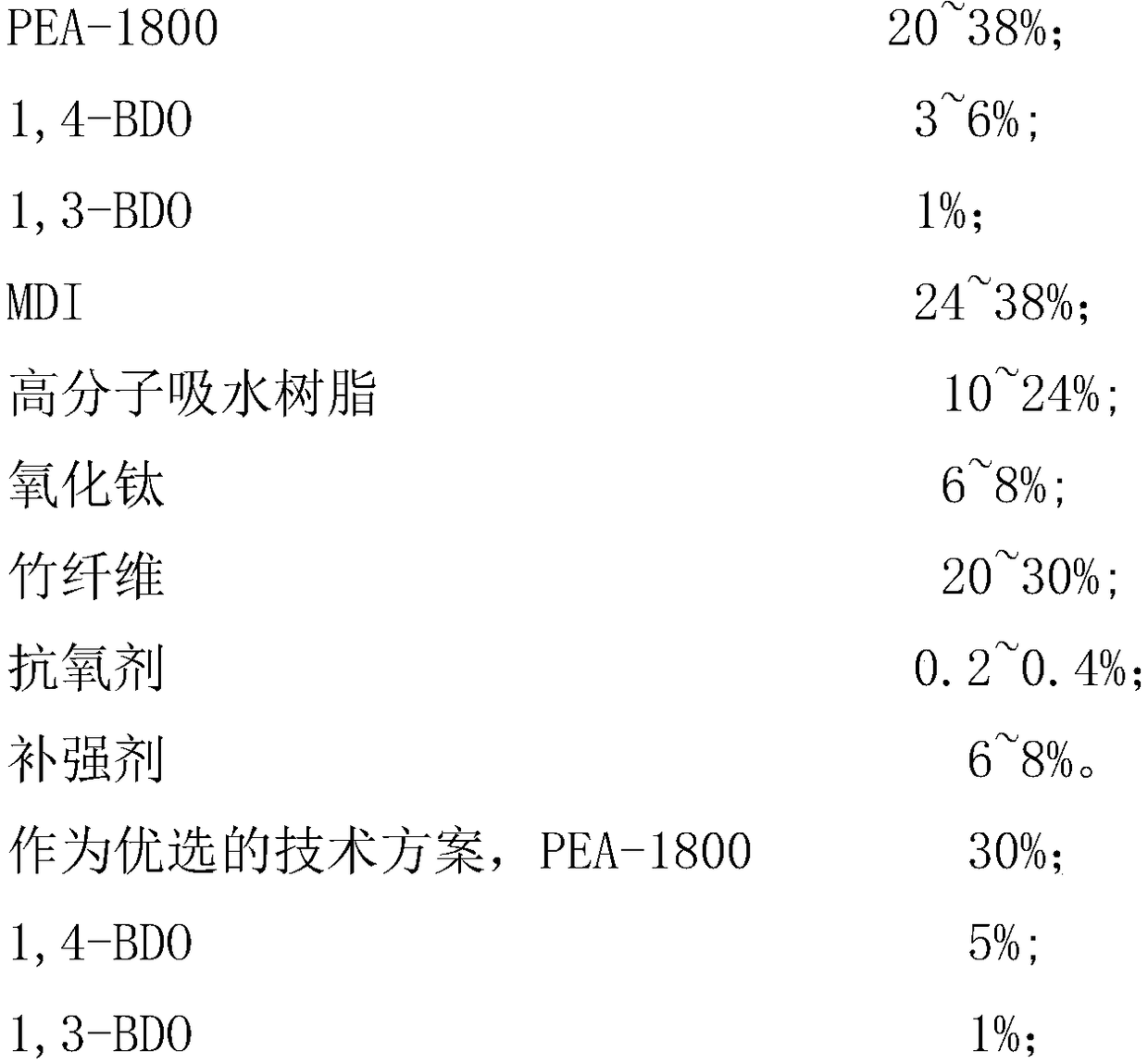

[0044] 1. Weigh 20% by weight of PEA-1800; 3% by weight of 1,4-BDO; 1% by weight of 1,3-BDO; 24% by weight of MDI; Resin; 6% by weight of titanium oxide; 20% by weight of bamboo fiber; 0.2% by weight of antioxidant; 6% by weight of reinforcing agent.

[0045] 2. Put 1,4-BDO, 1,3-BDO and PEA-2000 in the No. 1 reaction kettle, stir and mix evenly at a constant speed, then add polymer water-absorbent resin, titanium oxide, bamboo fiber, antioxidant and reinforcement agent, the temperature is set at 80°C; MDI is placed in the No. 2 reactor, and the set temperature is 75°C;

[0046] 3. When the temperature is stable, it is mixed through the high-speed rotating mixing head with a perfusion metering system, so that the molecules of various raw materials are fully collided and mixed, and then flow into the conveyor belt equipped with a ripening plate, and then pass through the drying tunnel equipped with 10 sections of oven. The oven temperature is set The heating temperature is set ...

Embodiment 2

[0050] 1. Weigh 38% by weight of PEA-1800; 6% by weight of 1,4-BDO; 1% by weight of 1,3-BDO; 38% by weight of MDI; Resin; 8% by weight of titanium oxide; 30% by weight of bamboo fiber; 0.4% by weight of antioxidant; 8% by weight of reinforcing agent.

[0051] 2. Put 1,4-BDO, 1,3-BDO and PEA-2000 in the No. 1 reaction kettle, stir and mix evenly at a constant speed, then add polymer water-absorbent resin, titanium oxide, bamboo fiber, antioxidant and reinforcement agent, the temperature is set at 90°C; MDI is placed in the No. 2 reactor, and the set temperature is 85°C;

[0052] 3. When the temperature is stable, it is mixed through a high-speed rotating mixing head with a perfusion metering system, so that the molecules of various raw materials are fully collided and mixed, and then flow into the conveyor belt equipped with a ripening plate, and then pass through the drying tunnel equipped with 14 sections of ovens. The oven temperature is set The heating temperature is set at ...

Embodiment 3

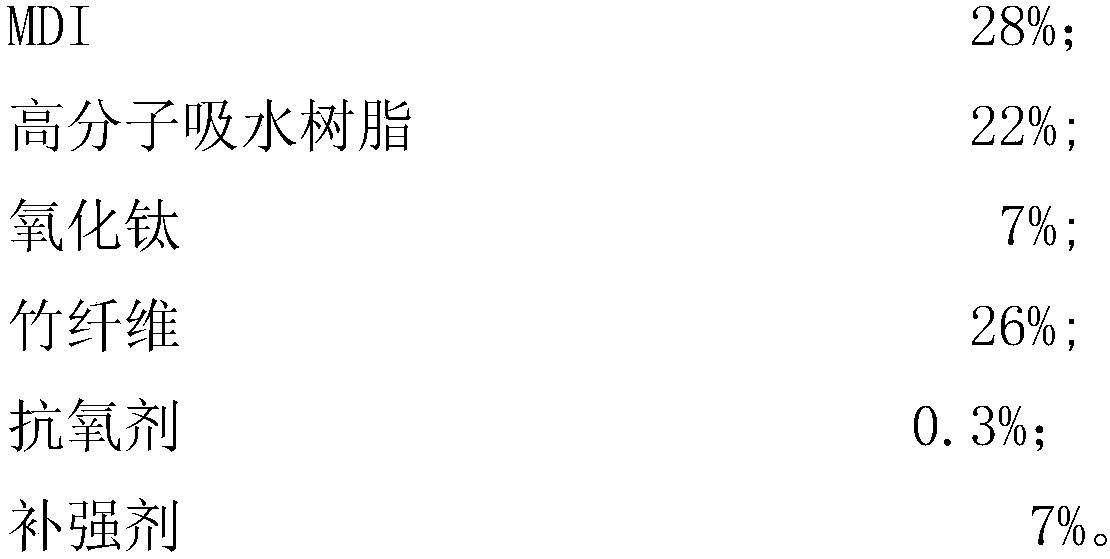

[0056] 1. Weigh 30% by weight of PEA-1800; 5% by weight of 1,4-BDO; 1% by weight of 1,3-BDO; 28% by weight of MDI; Resin; 7% by weight of titanium oxide; 26% by weight of bamboo fiber; 0.3% by weight of antioxidant; 7% by weight of reinforcing agent.

[0057] 2. Put 1,4-BDO, 1,3-BDO and PEA-2000 in the No. 1 reaction kettle, stir and mix evenly at a constant speed, then add polymer water-absorbent resin, titanium oxide, bamboo fiber, antioxidant and reinforcement agent, the temperature is set at 85°C; MDI is placed in the No. 2 reactor, and the set temperature is 80°C;

[0058] 3. When the temperature is stable, it is mixed through the high-speed rotating mixing head with a perfusion metering system, so that the molecules of various raw materials are fully collided and mixed, and then flow into the conveyor belt equipped with a ripening plate, and then pass through the drying tunnel equipped with 12 sections of ovens. The temperature of the oven is set Set at 100°C, the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com