Efficient paper making sewage treatment agent as well as preparation method and application thereof

A technology for papermaking sewage and treatment agent, applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of toxicity, secondary pollution of water quality, low efficiency of sewage treatment, etc. Low cost, environmental protection, good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

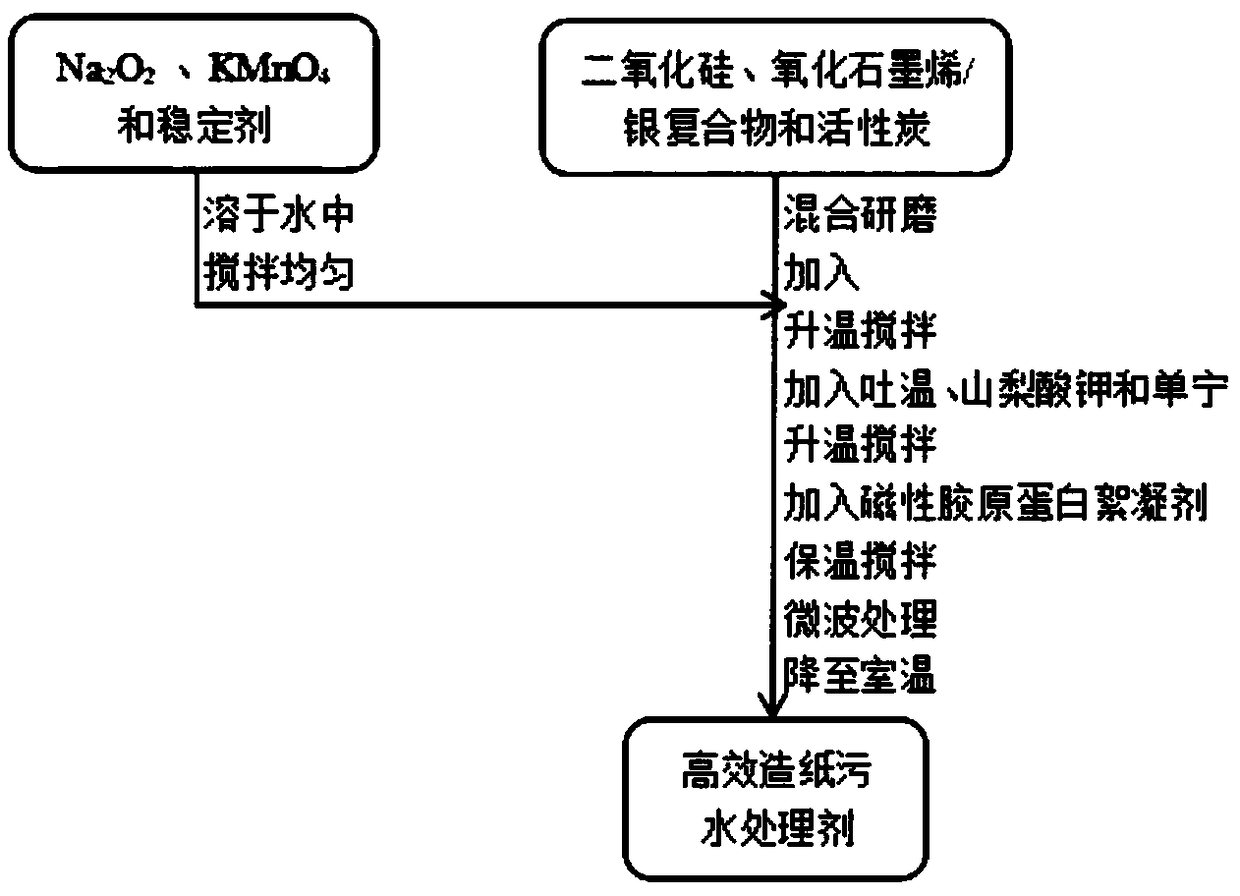

Method used

Image

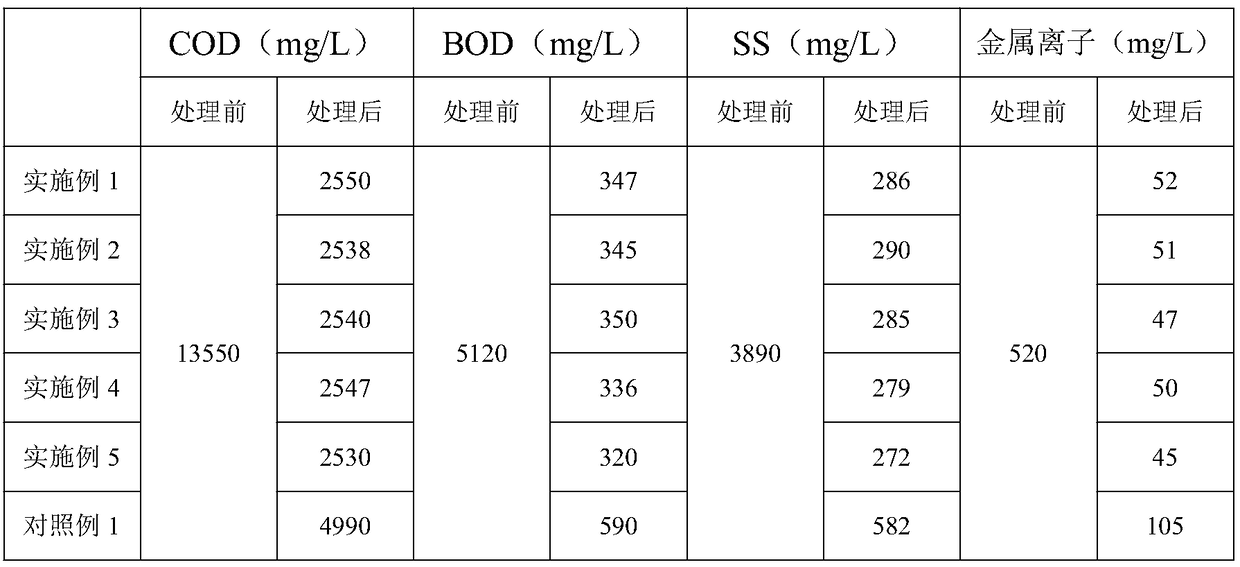

Examples

Embodiment 1

[0024] The preparation of embodiment 1 efficient papermaking sewage treatment agent

[0025] Raw material composition: 100 parts of magnetic collagen flocculant; Na 2 o 2 40 parts; KMnO 4 30 parts; phosphite ester 10 parts, epoxidized soybean oil 10 parts; potassium sorbate 20 parts; silicon dioxide 20 parts; graphene oxide / silver composite 10 parts; activated carbon 20 parts; Tween 10 parts; tannin 5 parts parts; 100 parts of water.

[0026] Preparation of magnetic collagen flocculant: 163g FeCl 2 2H 2 O and 541g FeCl 3 ·6H 2 Dissolve O in deionized water under a constant temperature water bath at 50°C, weigh 1000g of collagen flocculant, put it into the prepared iron salt solution, and add 1mol / L NaOH solution drop by drop under vigorous stirring until the pH is 7.5 , after the glue solution turns brown-black, continue to stir for 30 minutes, put the obtained polymer gel in a drying oven for 24 hours, and dry at a temperature of 40°C to obtain a black block and grind ...

Embodiment 2

[0030] The preparation of embodiment 2 efficient papermaking sewage treatment agent

[0031] Raw material composition: 120 parts of magnetic collagen flocculant; Na 2 o 2 50 parts; KMnO 4 50 parts; hindered phenol 40 parts; potassium sorbate 30 parts; silicon dioxide 40 parts; graphene oxide / silver composite 30 parts; activated carbon 40 parts; Tween 20 parts; tannin 15 parts; water 150 parts.

[0032] Preparation of magnetic collagen flocculant: 163g FeCl 2 2H2 O and 541g FeCl 3 ·6H 2 Dissolve O in deionized water under a constant temperature water bath at 50°C, weigh 1200g of collagen flocculant, put it into the prepared iron salt solution, and add 1mol / L NaOH solution dropwise under vigorous stirring until the pH is 8 , after the glue solution turns brown-black, continue to stir for 30 minutes, put the obtained polymer gel in a drying box and dry for 24 hours at a drying temperature of 50°C to obtain a black block and grind it to obtain magnetic collagen flocculant pow...

Embodiment 3

[0036] The preparation of embodiment 3 efficient papermaking sewage treatment agent

[0037] Composition of raw materials: 107 parts of magnetic collagen flocculant; Na 2 o 2 42 parts; KMnO 4 35 parts; zinc stearate 22 parts; potassium sorbate 22 parts; silicon dioxide 23 parts; graphene oxide / silver composite 15 parts; activated carbon 23 parts; Tween 12 parts; tannin 7 parts;

[0038] Preparation of magnetic collagen flocculant: 163g FeCl 2 2H 2 O and 541g FeCl 3 ·6H 2 Dissolve O in deionized water under a constant temperature water bath at 50°C, weigh 1100g of collagen flocculant, put it into the prepared iron salt solution, and add 1mol / L NaOH solution drop by drop under vigorous stirring until the pH is 7.7 , after the glue solution turns brown-black, continue to stir for 30 minutes, put the obtained polymer gel in a drying oven and dry for 24 hours at a drying temperature of 45°C to obtain a black block and grind it to obtain magnetic collagen flocculant powder bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com