Automatic surface-cutting, edge-sealing, pressing and trimming system for boards and method comprising automatic surface-cutting, edge-sealing, pressing and trimming system

A technology for cutting surfaces and plates, applied in the field of automatic plate cutting, edge sealing, pressing and trimming systems, which can solve the problems of reduced practical reliability, complex overall structure, poor automation, etc., to improve work efficiency, high degree of automation, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

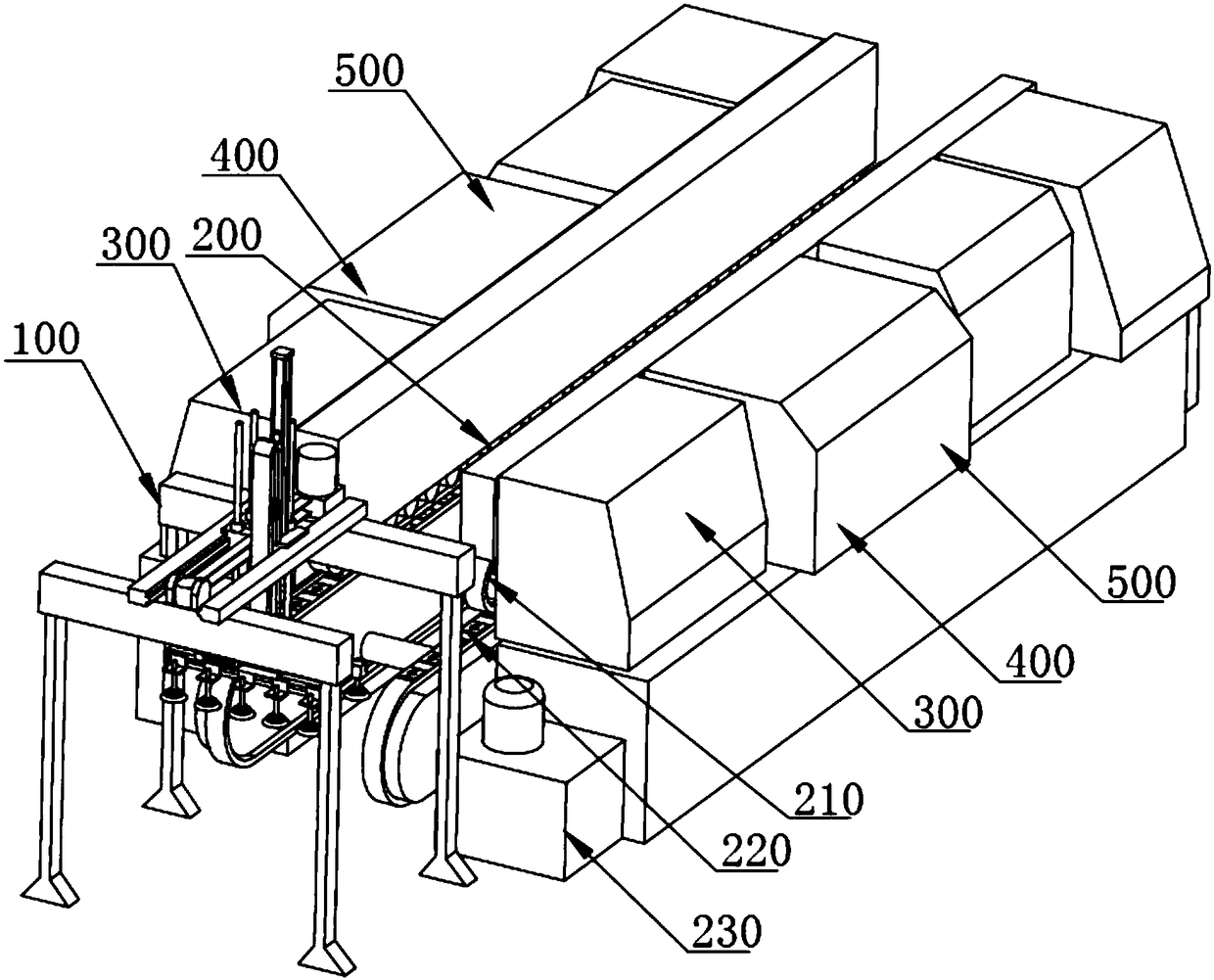

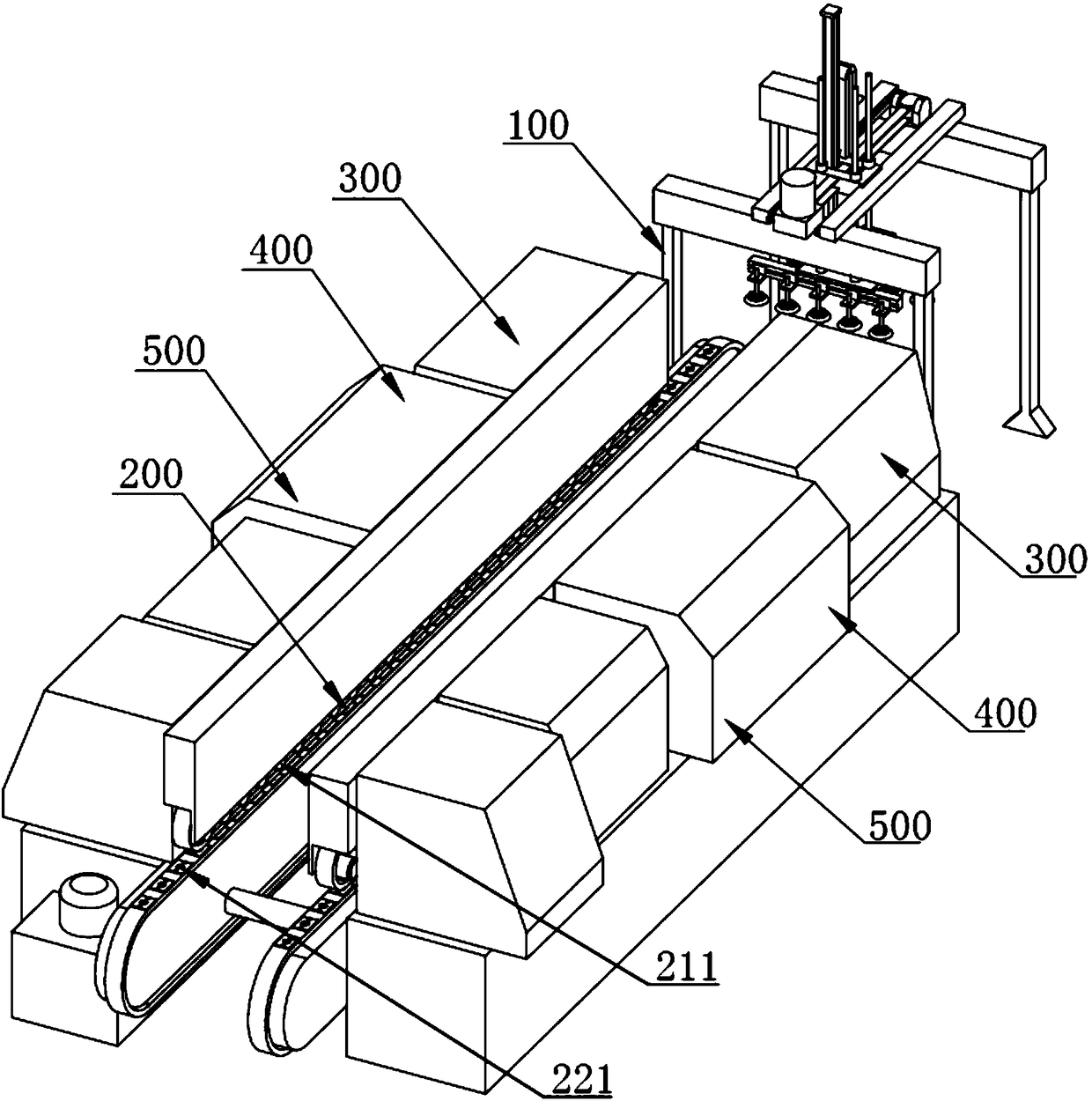

[0047] Such as Figure 1 ~ Figure 2 As shown, a plate automatic surface cutting, gluing, edge sealing and pressing system includes a feeding device 100, a conveying device 200, a surface cutting device 300 and an edge sealing device 400, and the surface cutting device 300 and the edge sealing device 400 are arranged in sequence The conveying device 200, the feeding device 100 is located on one side of the conveying device 200, the cutting device 300 includes a base 310 and a first cutting module 320 and a second cutting module 330 arranged in sequence, the first cutting The noodle module 320 is installed on the base 310 , and the first noodle cutting module 320 and the second noodle cutting module 330 both correspond to the conveying device 200 .

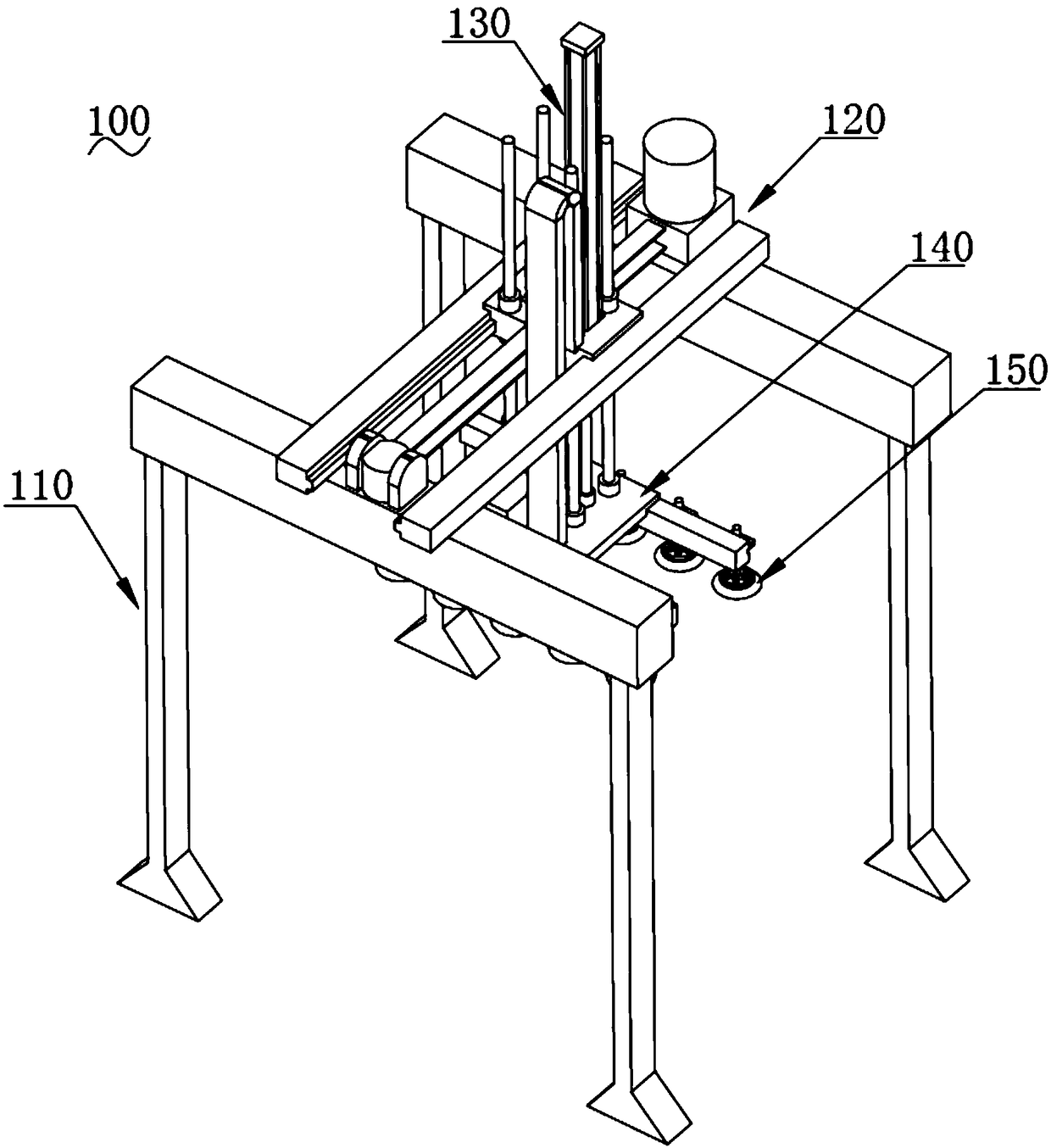

[0048] Such as Figure 3 ~ Figure 6 As shown, a system for automatically cutting, sealing, and trimming plates includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com