Bamboo diatom board

A technology of diatom board and bamboo wood, which is applied in the field of bamboo wood board, can solve the problems of single function of bamboo board, inability to effectively use diatomite, and failure to meet the needs of use, and achieve simple preparation method, high hardness and improved function sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention proposes a bamboo wood diatom board, including the following raw materials by weight: 10 parts of diatomaceous earth, 20 parts of straw, 3 parts of calcium carbonate, 4 parts of plant fiber, 5 parts of zinc stearate, 10 parts of bamboo charcoal powder, and paraffin wax 2 parts, 3 parts of silane coupling agent, 5 parts of epoxy resin, 30 parts of moso bamboo, 10 parts of wood flour;

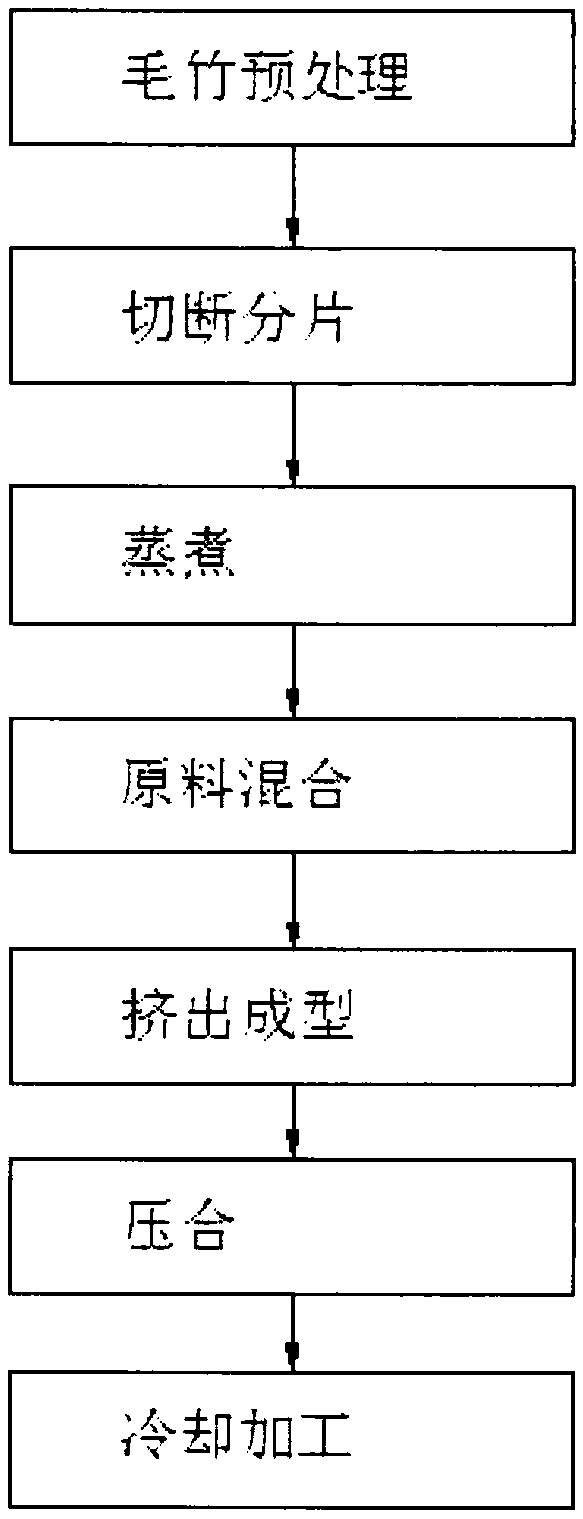

[0025] The preparation method includes the following steps:

[0026] S1: Moso bamboo pretreatment: Choose 4 years old moso bamboo as raw material, clean the moso bamboo, dry it after cleaning, and dry it for 1 hour, so that the moisture content of moso bamboo is 1%;

[0027] S2: Cutting and slicing: cutting the pretreated moso bamboo described in S1, cutting off the bamboo joints, scraping off the green bamboo, cutting the moso bamboo, roughing and slicing the inside of the moso bamboo;

[0028] S3: Steaming: Put the flaky bamboo described in S2 into the cooking furnace, set ...

Embodiment 2

[0034] The present invention proposes a bamboo wood diatom board, which includes the following raw materials in parts by weight: 20 parts of diatomaceous earth, 25 parts of straw, 5 parts of calcium carbonate, 7 parts of plant fiber, 10 parts of zinc stearate, 12 parts of bamboo charcoal powder, and paraffin wax 5 parts, 5 parts of silane coupling agent, 7 parts of epoxy resin, 10 parts of moso bamboo, 15 parts of wood flour;

[0035] The preparation method includes the following steps:

[0036] S1: Pretreatment of Moso bamboo: Choose 5 years old Moso bamboo as raw material, clean the Moso bamboo, dry it after cleaning, and dry it for 2h, so that the moisture content of Moso bamboo is 5%;

[0037] S2: Cutting and slicing: cutting the pretreated moso bamboo described in S1, cutting off the bamboo joints, scraping off the green bamboo, cutting the moso bamboo, roughing and slicing the inside of the moso bamboo;

[0038] S3: Steaming: Put the flaky bamboo described in S2 into the cooking...

Embodiment 3

[0044] The present invention proposes a bamboo wood diatom board, which includes the following raw materials in parts by weight: 30 parts of diatomaceous earth, 30 parts of straw, 8 parts of calcium carbonate, 10 parts of plant fiber, 15 parts of zinc stearate, 15 parts of bamboo charcoal powder, and paraffin wax 7 parts, 8 parts of silane coupling agent, 10 parts of epoxy resin, 50 parts of moso bamboo, 20 parts of wood flour;

[0045] The preparation method includes the following steps:

[0046] S1: Pretreatment of moso bamboo: choose 6-year-old moso bamboo as the raw material, clean the moso bamboo, dry it after cleaning, and dry it for 3 hours to make the moso bamboo have 8% moisture content;

[0047] S2: Cutting and slicing: cutting the pretreated moso bamboo described in S1, cutting off the bamboo joints, scraping off the green bamboo, cutting the moso bamboo, roughing and slicing the inside of the moso bamboo;

[0048] S3: Steaming: Put the flaky bamboo described in S2 into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com