Circular cleaning device for automobile brake pads

A technology for cleaning devices and brake pads, which is applied in the direction of cleaning methods using liquids, cleaning methods using tools, cleaning methods and utensils, etc., which can solve problems such as waste of water resources, potential safety hazards, and inability to ensure that brake pads are cleaned in place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

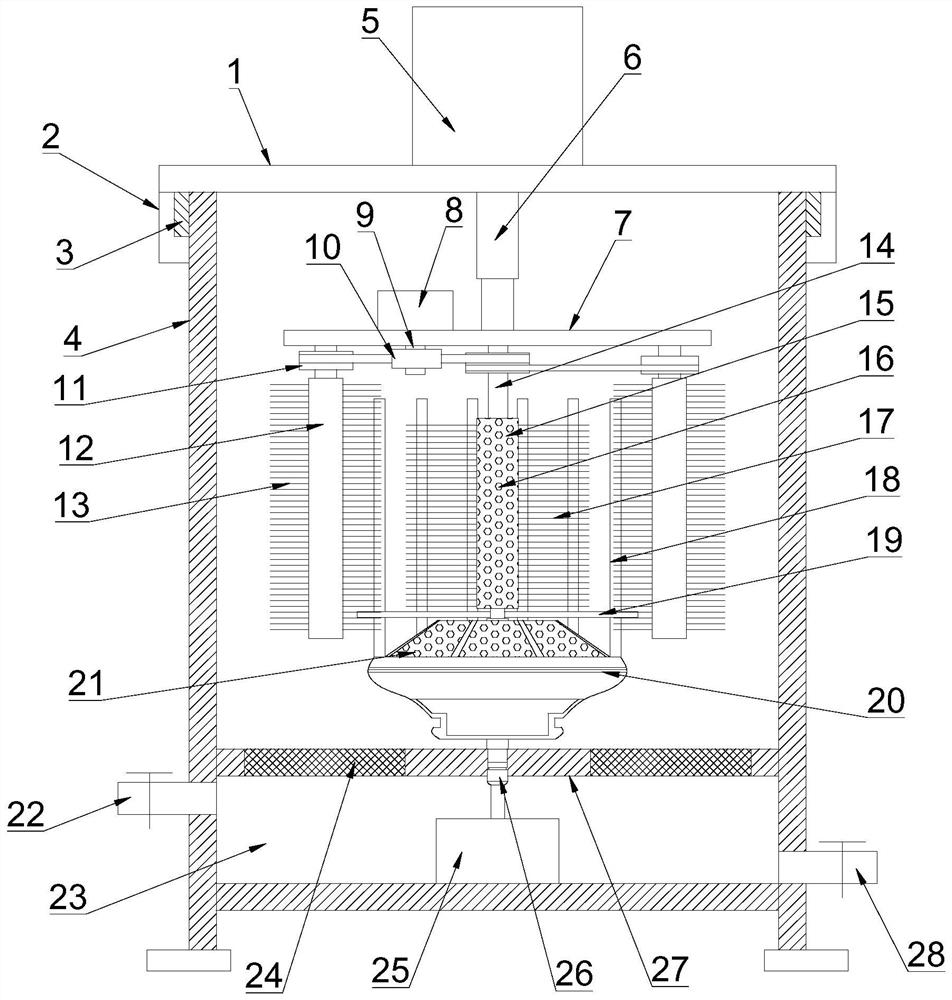

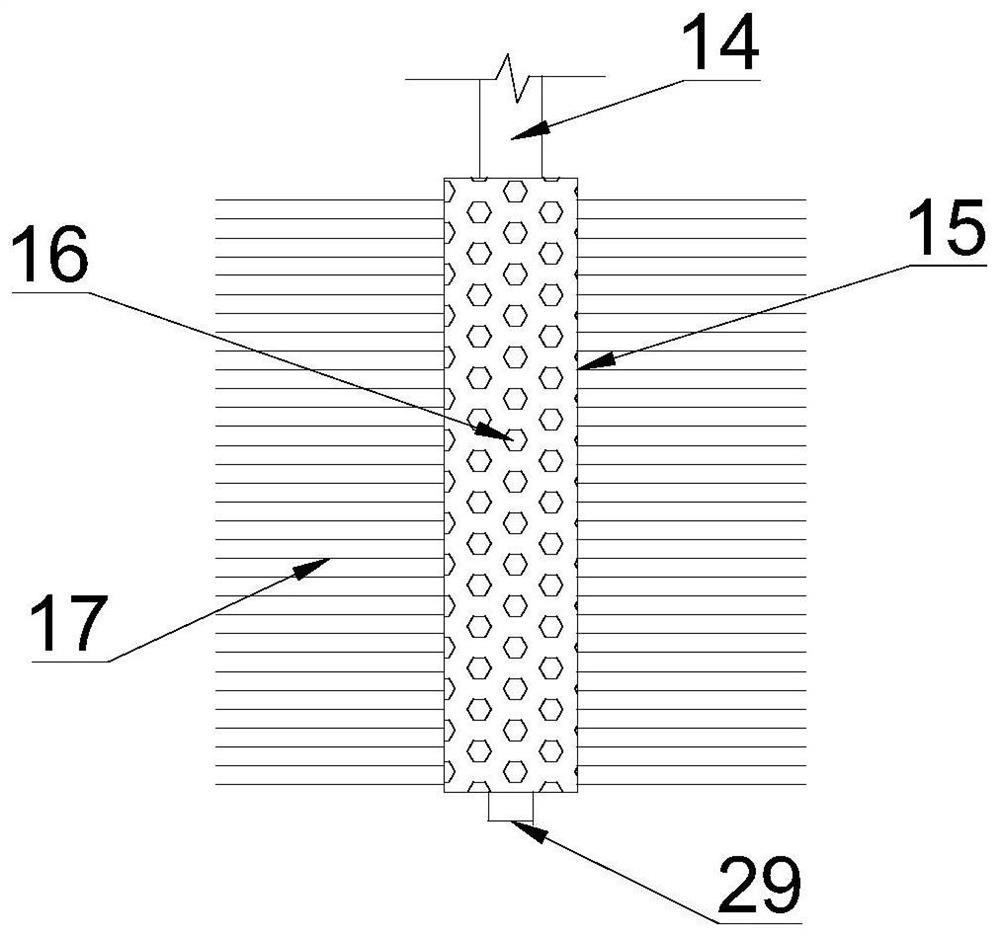

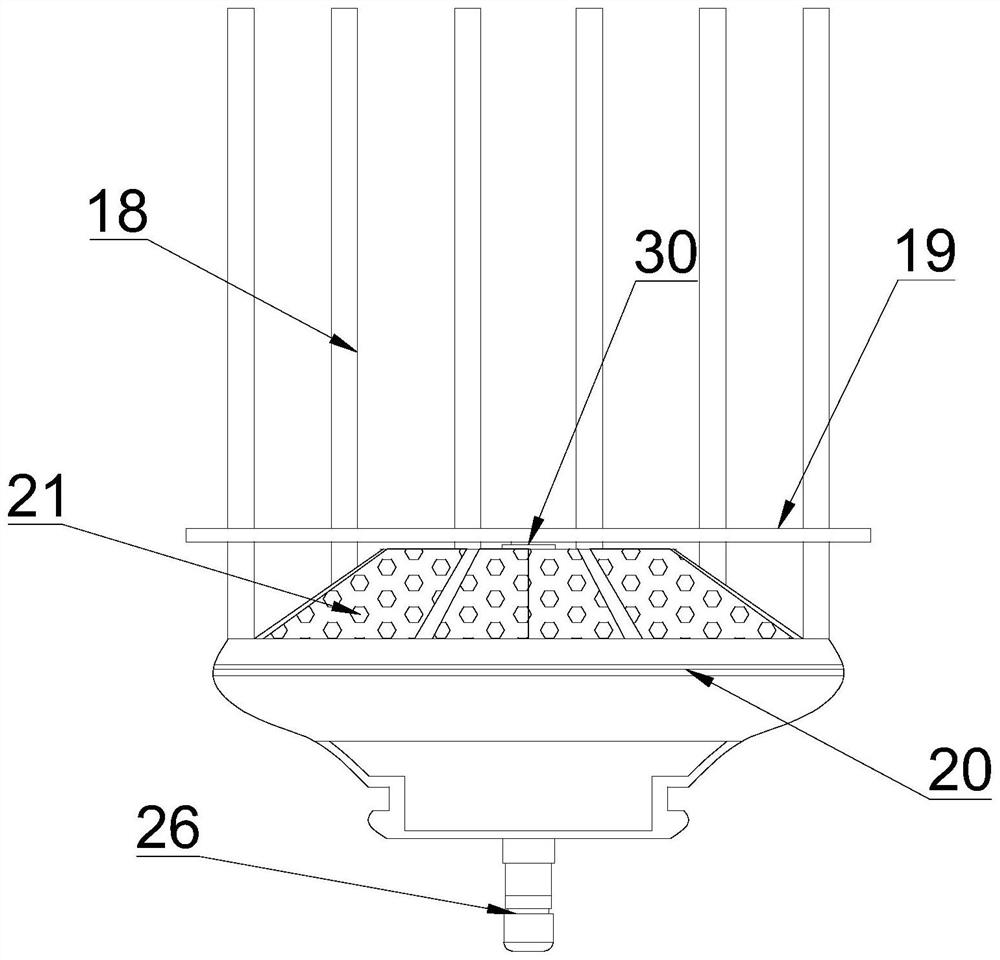

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] see Figure 1-4 , a circular cleaning device for automobile brake pads, comprising a cleaning cylinder cover 1, a cleaning cylinder body 4, a lifting plate 7, a drive sprocket 10, an outer cleaning roller 12, an inner cleaning roller 15, an assembly rod 18 and a cleaning seat 20, The cleaning cylinder cover 1 is installed on the top of the cleaning cylinder 4, and the cleaning cylinder cover 1 and the cleaning cylinder 4 are fastened and connected by the lock 2 and the lock tongue 3, the lock 2 is hinged on the outside of the cleaning cylinder cover 1, and the lock tongue 3 is fixed on the outer wall of the top end of the cleaning cylinder 4, and the lock catch 2 and the lock tongue 3 are fastened to realize the fixed connection between the two. The electric cylinder 5 is installed in the middle of the top end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com