Glue dispensing equipment with high accuracy and load, and control method

A high-load, high-precision technology, applied to the device and coating of the surface coating liquid, can solve the problems of inability to process at the same time, not easy to carry, large volume, etc., to achieve miniaturized production, convenient operation, and reduce volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

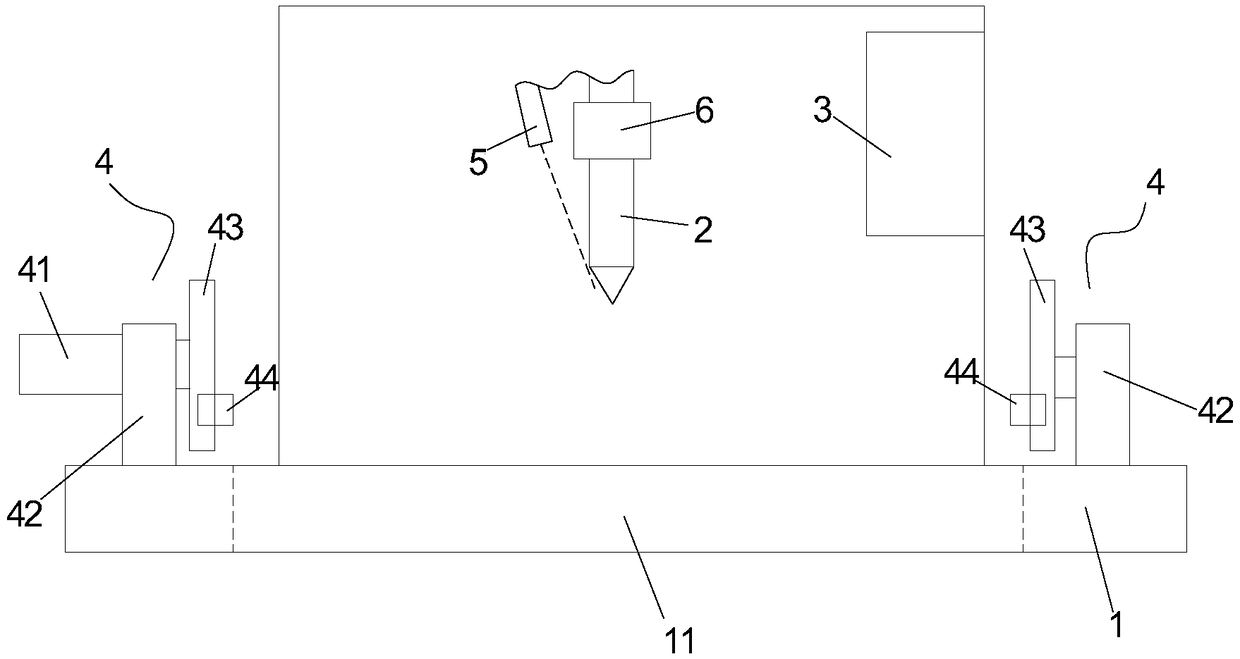

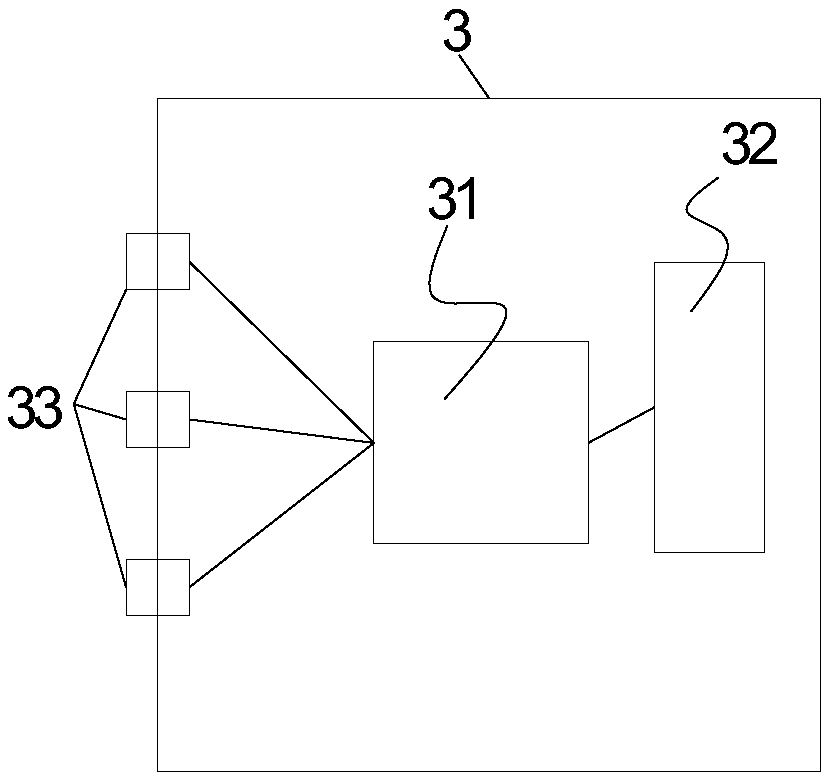

[0023] See attached figure 1 , figure 2 As shown, a high-precision and high-load dispensing equipment in this embodiment includes a dispensing workbench 1 and a gantry cantilever three-dimensional motion structure arranged on the dispensing workbench 1. The gantry cantilever three-dimensional motion structure The motion structure includes a metering and dispensing device 2 and a control electric box 3 with a built-in control main board 31. The control main board 31 is integrated with a signal transceiver module 32, and the control electric box 3 is provided with an interface unit 33 connected to the control main board; The dispensing workbench is also provided with a turning mechanism 4 for clamping the workpiece, and the turning mechanism 4 is driven by a servo motor 41 to realize the 360° rotation of the workpiece. The above-mentioned interface unit 33 includes RS232, USB3.0, and HDMI interfaces.

[0024] The signal transceiver module 32 supports the 5G of the mobile phon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com