Ball grinding and mixing device

A mixing device and ball milling technology, applied in the direction of solid separation, sieve, grid, etc., can solve the problems of non-layered abrasives and uneven mixing of raw materials, and achieve the effect of good cleaning effect and maintaining cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

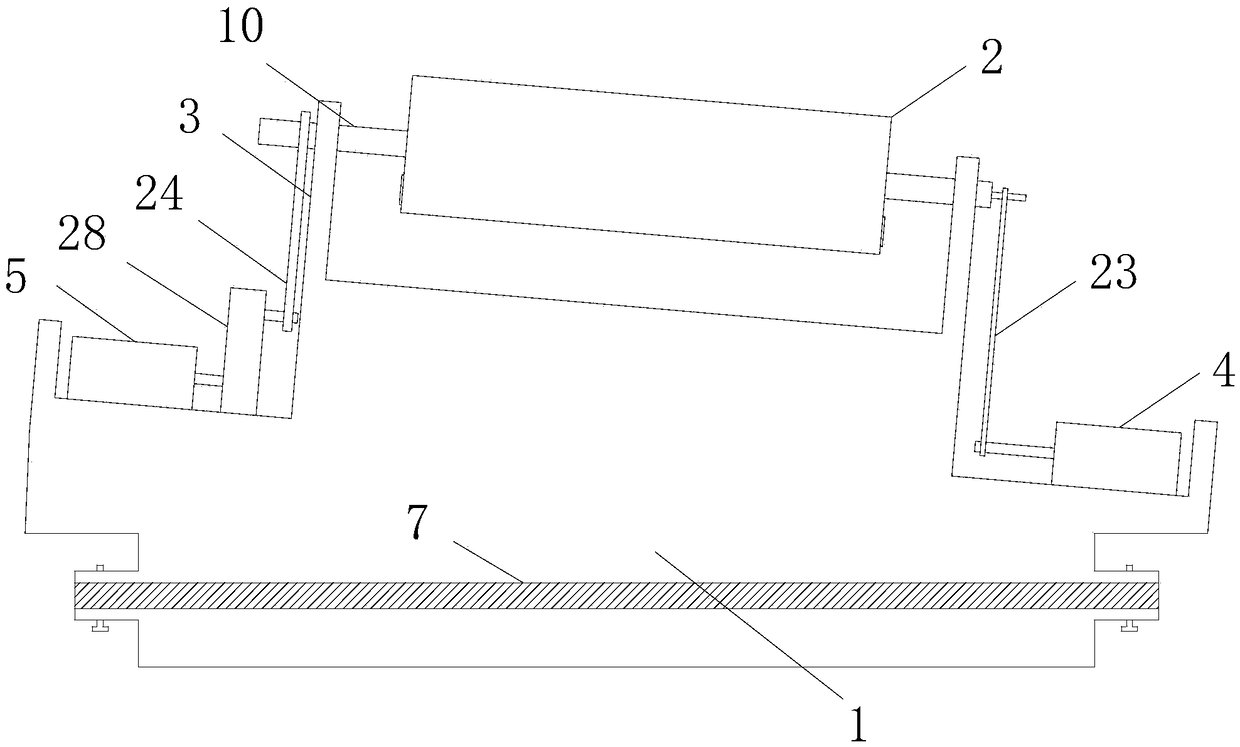

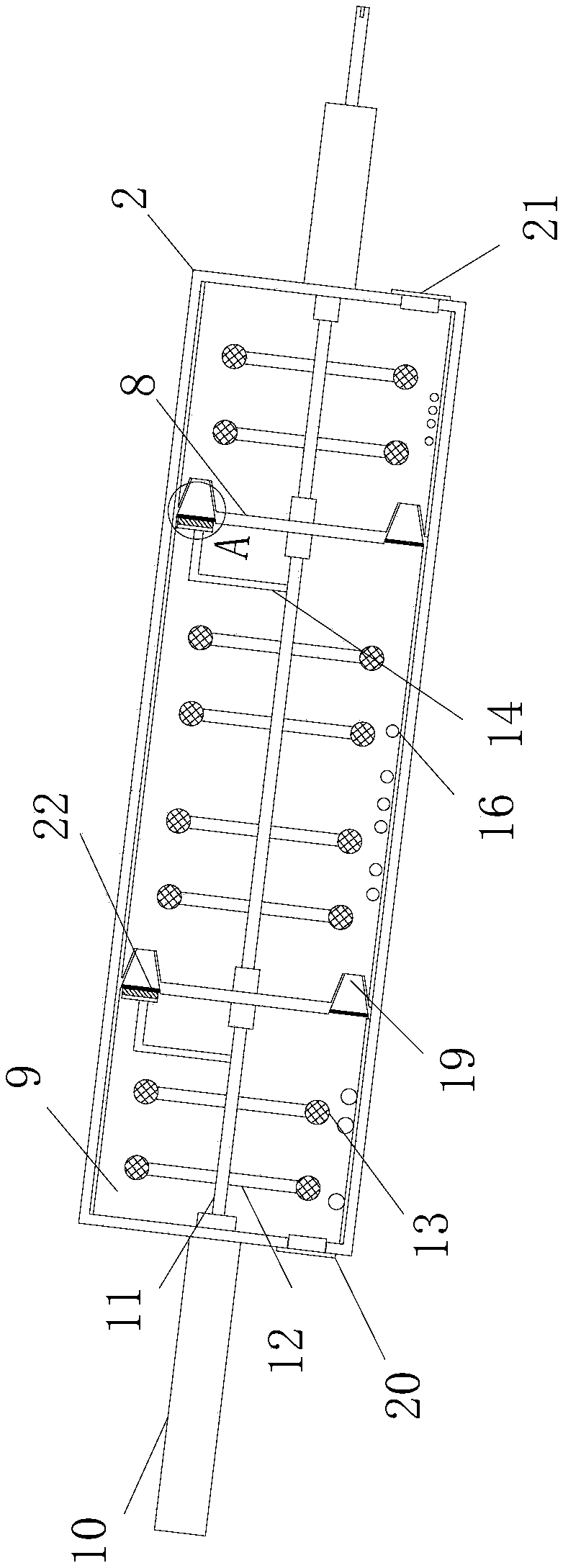

[0057] see figure 1 , figure 2 , image 3 with Figure 4 , The ball mill mixing device of this embodiment includes a drum 2, a plurality of grinding balls 16, a driving device 2, a device seat 1, a cleaning mechanism, and a stirring mechanism.

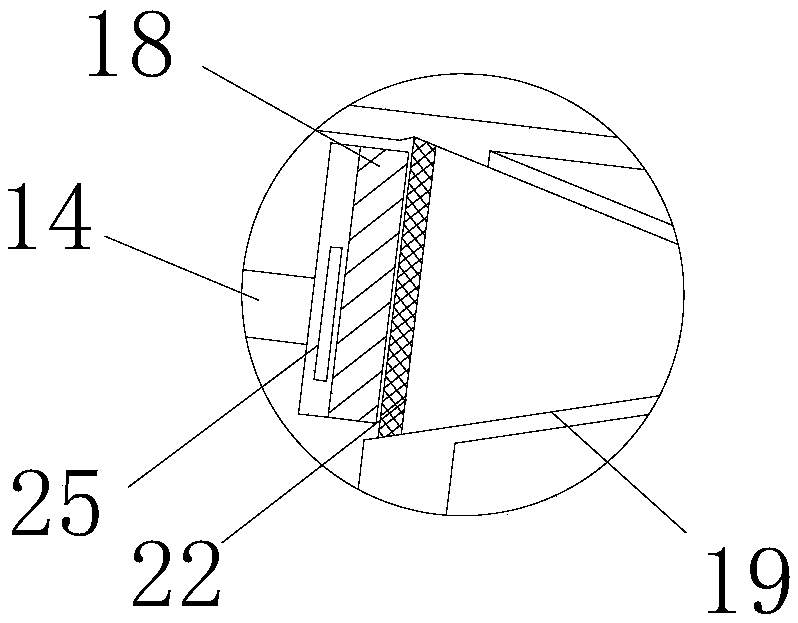

[0058]The drum 2 is inclined, and the inside of the drum 2 is divided into a plurality of grinding bins 9 sequentially along the direction of the drum 2's downward inclination through the partition board 8, and the plurality of grinding bins 9 are used for layered grinding of materials. Moreover, at least one opening is provided on the edge of each partition 8 , and a filter net 22 is arranged in each opening. The mesh diameter of each filter screen 22 decreases successively along the direction in which the drum 2 inclines downward. One side of each filter screen 22 is correspondingly provided with a funnel 19, and each funnel 19 is positioned at the side of the corresponding filter screen 22 along the direction of inclination of ...

Embodiment 2

[0071] Please combine Figure 5 and Figure 6 , the ball mill mixing device of this embodiment adds a scraping mechanism on the basis of Embodiment 1. When the drum 2 is performing abrasive operations, due to gravity, the material will form a certain angle at the angle between the partition 8 and the inner wall of the drum 2. Accumulation, and agglomeration will occur due to extrusion, and agglomerated materials are inconvenient for grinding. The scraping mechanism is used to scrape up the material accumulated on one side of the filter screen 22 when the drum 2 rotates. The scraping mechanism includes a plurality of extension rods 17 corresponding to a plurality of partitions 8 respectively. One end of the extension rod 17 is provided with a scraper 15 close to the inner wall of the cylinder 2, and the other end of the extension rod 17 is fixedly connected to the inner shaft 11. When the drum 2 rotates, the scraper 15 can scrape up the materials attached to one side of the f...

Embodiment 3

[0075] see Figure 7 , The ball mill mixing device of this embodiment adds another reduction box 27 on the basis of Embodiment 1. Gear box 27 is used for carrying out deceleration transmission to motor one 4, and gear box 27 is positioned at an end outside cylinder 2 through transmission chain one 23 transmission connections of inner shaft 11.

[0076] Wherein, when the motor one 4 starts, the reduction box 27 decelerates the motor one 4 and outputs a larger torque, and then drives the inner shaft 11 to rotate through the transmission chain one 23 . The reduction box 27 makes the force driving the rotation of the inner shaft 11 larger, so that a larger amount of material can be processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com